Energy-absorbing automobile engine suspension

A technology for engine mounts and automobile engines, which is applied in power units, mechanical equipment, vehicle components, etc., can solve the problems of high natural vibration frequency, poor integrity, and cannot meet the requirements of vibration reduction and noise reduction, so as to reduce the occupation. Space and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

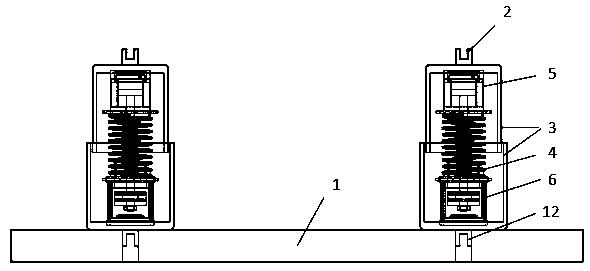

[0057] Said energy-absorbing engine mount, one end is fixedly connected to the engine damping block 1 on the chassis of the automobile through the installation buckle 2, and the other end is fixedly connected to the automobile engine through the installation buckle 12, and the mount includes the installation buckle 2 , mounting buckle 12, shell 3, spiral wire rope shock absorber 4, hydraulic damper 5 and magnetorheological damper 6, etc., said shell 3 includes upper and lower shells, non-contact installation, to ensure that the engine suspension moves up and down There is no interference in the process.

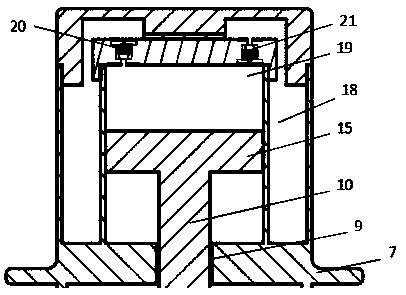

[0058] The spiral wire rope shock absorber 4 includes a limit plate one 7, a limit plate two 8, an annular ventilation duct 9, a spiral steel wire rope 17, a guide rod one 10, and a guide rod two 11. Described limiting plate one 7 and limiting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com