I-shaped steel socket type tramcar prefabricated track beam and tubular pile connecting structure and construction method

A technology of I-shaped steel and trams, which is applied in the direction of infrastructure engineering, tracks, laying tracks, etc., can solve the problems of slow construction time, many manpower required, and difficult positioning, and achieve short construction time, good physical properties, The effect of less manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

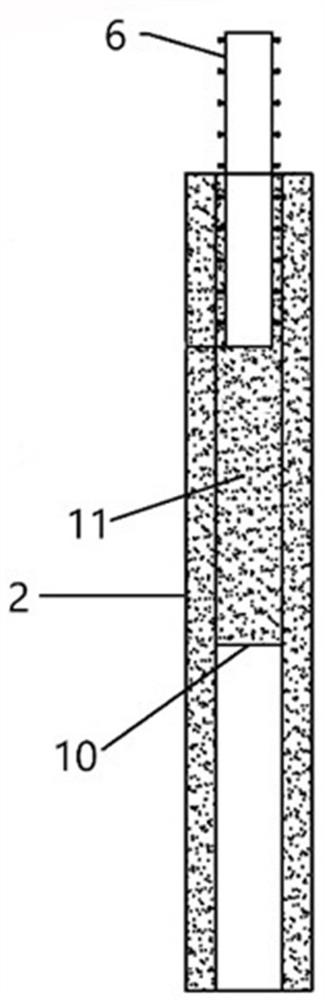

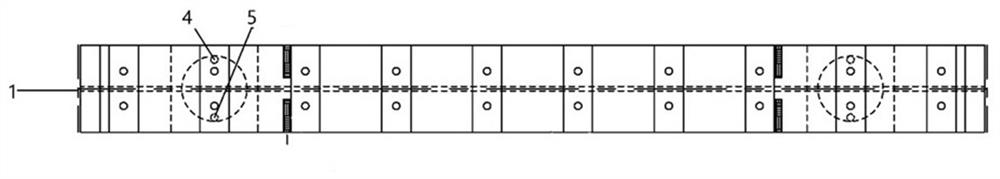

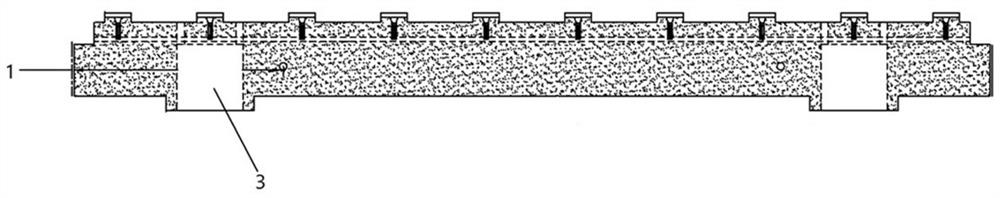

[0039] Example: The I-shaped steel socket tram prefabricated rail beam and pipe pile connection structure in the present embodiment, for realizing the connection between the hollow pipe pile 1 and the prefabricated track beam 2.

[0040] as Figure 1As shown, the hollow pipe pile 1 is provided with a pallet 10 inside, the pallet 10 is fixedly connected to the inner wall of the pile hole of the hollow pipe pile 1. Above the pallet 10 is poured ultra-high performance concrete 11, the ultra-high performance concrete 11 is carried by the pallet 10. Embedded in the interior of the ultra-high performance concrete 11 is an I-beam 6, which is connected to the hollow pipe pile 1 by the ultra-high performance concrete 11. as Figure 5 As shown, the peripheral integral molding of I-beam 6 is provided with quadrature shear nails 7, oblique shear nails 8, and oblique shear nails 9; anti-shear nails provide shear stress for the connecting structure in three different forms. The lengths of quadrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com