Curtain wall system capable of discretionarily being demounted, mounted and changed

A technology for curtain walls and unit components, applied in walls, building components, buildings, etc., can solve the problems of large unit components, high cost, and difficulty in effectively ensuring project quality, and achieve the effect of strengthening extrusion and sealing and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

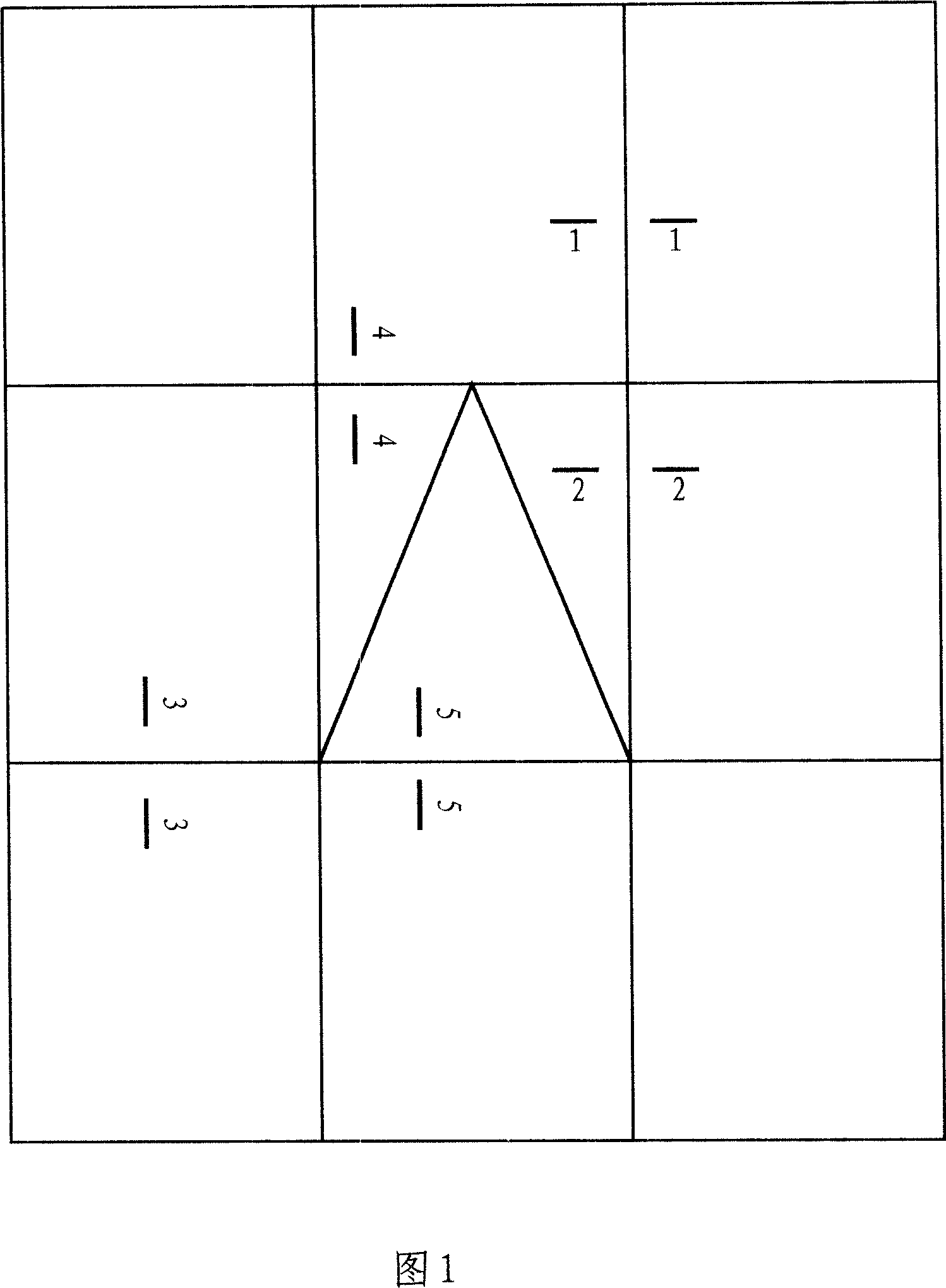

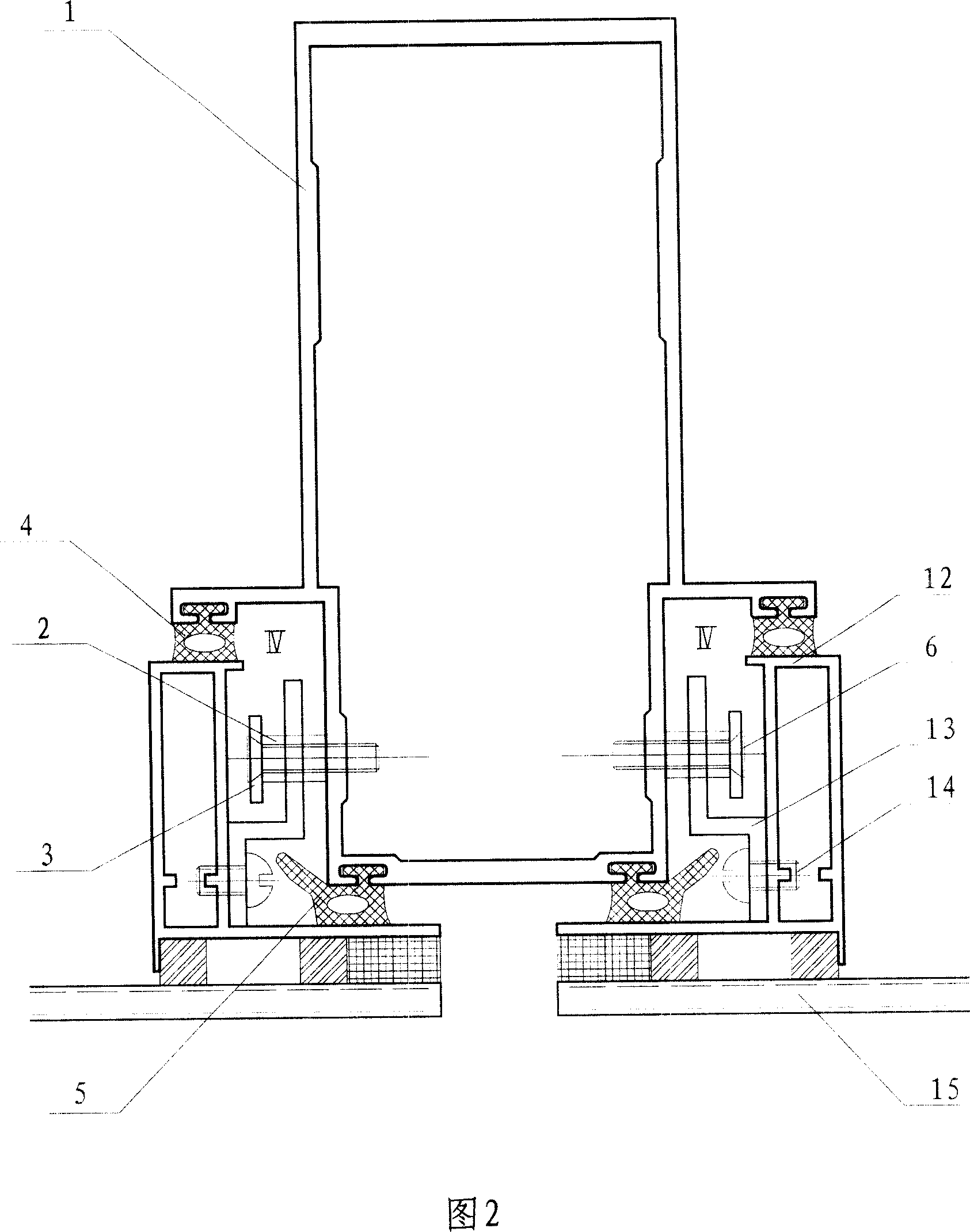

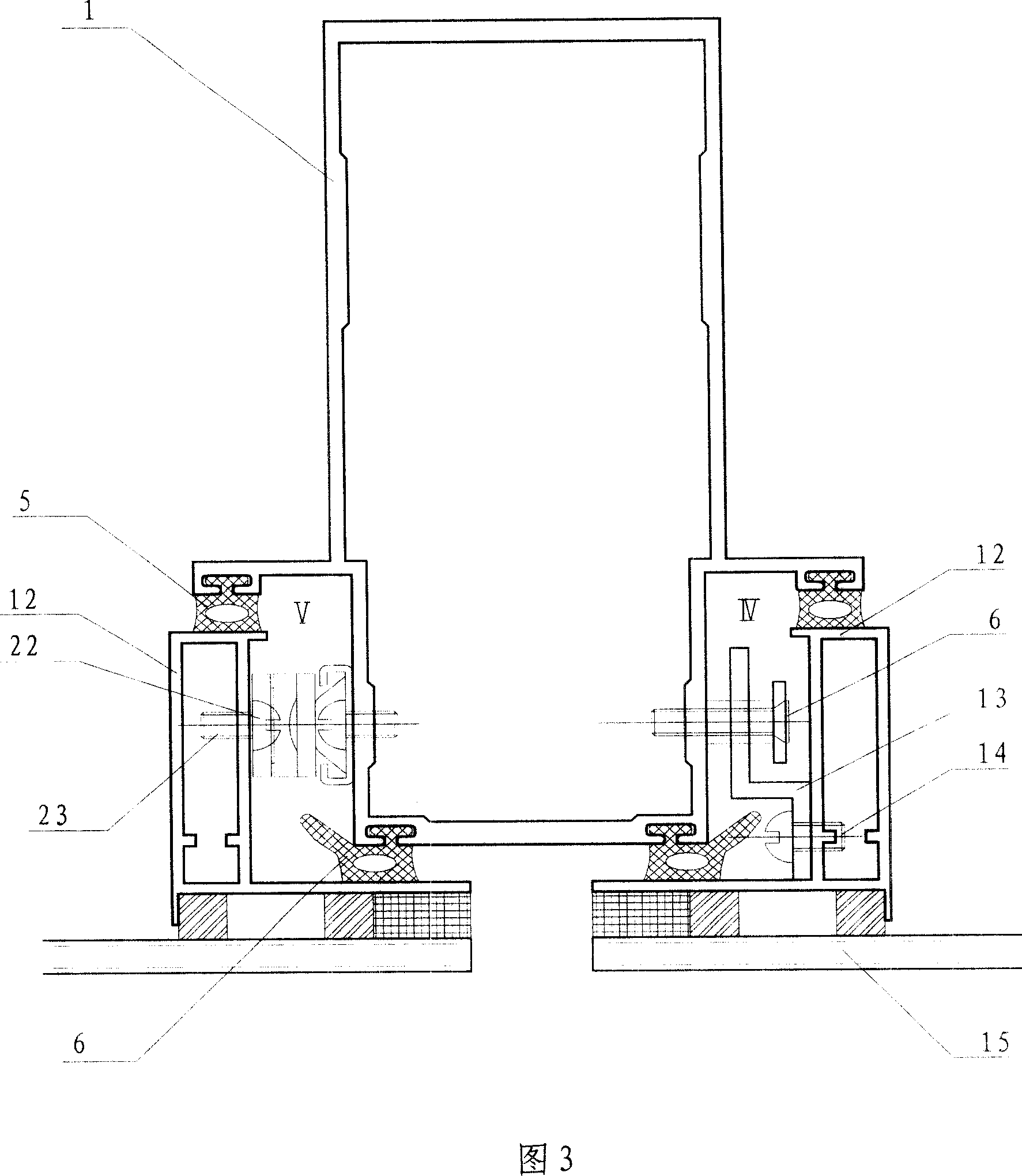

[0027] In order to better illustrate the working principle of the present invention, the following words will be adopted herein:

[0028] Stile assembly: the stile assembly in the present invention includes the stile 1, the stile seal strips 4 and 5, the stile hanging rod 2, the anti-drop plate 3 and the mechanism for connecting the hanging rod and the hanging plate to the stile screw6. When processing the stile, install it on the stile first according to the requirements of the processing drawing, and install it together with the stile as a whole.

[0029] Fixed unit: The fixed unit assembly mentioned in the present invention is installed on the stile, not used as a unit assembly for opening ventilation: including the upper horizontal frame 7, the upper horizontal frame sealing strips 8, 9, 10, the lower horizontal frame 11, Mullion 12, hook 13 installed on the mullion, mechanism screw 14 connecting the hook to the mullion, rubber strip 16 in the combination limit assembly, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com