Thermal radiation plate butt joint structure

A heat radiation plate and plate pair technology, which is applied in heat exchange equipment, heat exchanger shell, lighting and heating equipment, etc., can solve the problems that affect the service life of the product and peripheral failure, so as to improve the service life of the product and reduce the crack the possible effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

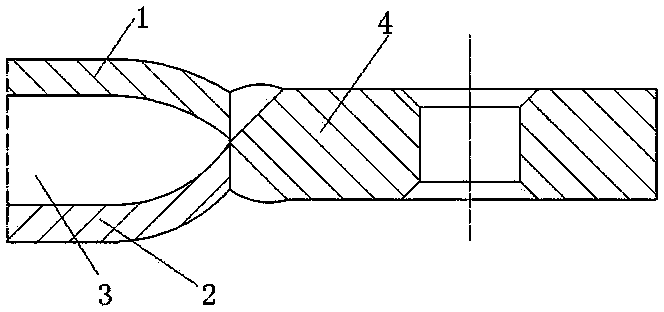

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

[0012] like figure 1 A heat radiation plate butt joint structure shown, including a plate pair,

[0013] The ends of the upper plate 1 and the lower plate 2 of the plate pair are bent toward the direction of the heat exchange medium flow channel 3,

[0014] It also includes slats 4 which extend along the ends of the pair of plates and are respectively fixedly connected with the upper plate 1 and the lower plate 2 at corresponding positions.

[0015] The plate pair is butt welded to the slat 4 with full penetration.

[0016] The invention relates to a butt joint structure of heat radiation plates. Due to the improved connection structure of the upper plate and the lower plate of the plate pair, the heat radiation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com