Sheet-like adhesive, gas barrier laminated body, and sealed body

A technology of adhesive layer and gas barrier layer, which is applied in the direction of adhesives, adhesive types, non-polymer adhesive additives, etc., can solve the problems of easy reduction of luminous brightness, luminous efficiency and luminous uniformity, and luminous characteristics. Achieve excellent interlayer adhesion and high inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

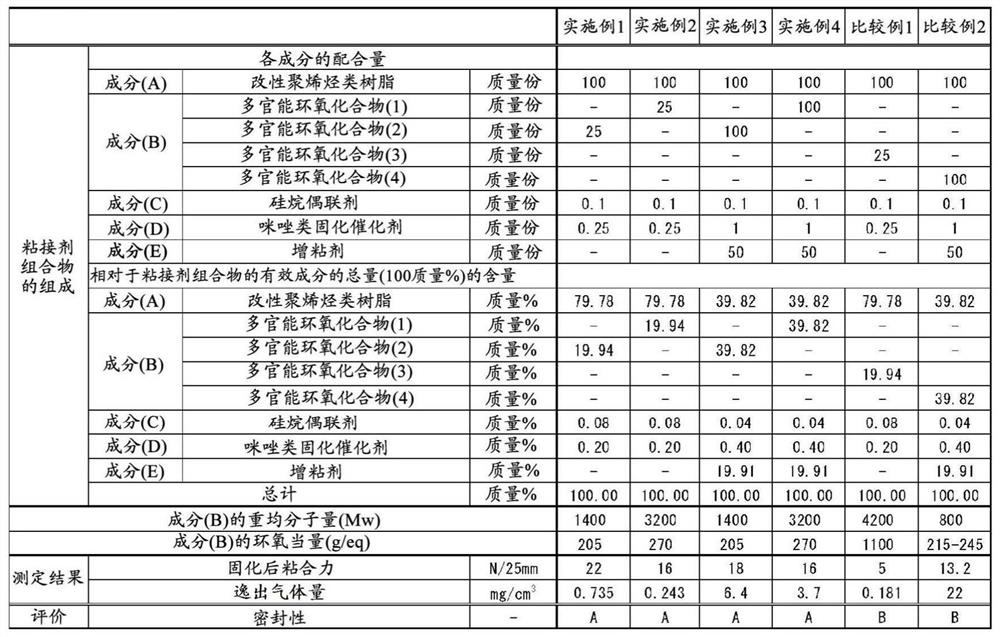

Embodiment 1~4、 comparative example 1~2

[0270] (1) Preparation of adhesive composition

[0271] Each component shown below was added according to the compounding quantity (active ingredient ratio) shown in Table 1, and it diluted with methyl ethyl ketone, and prepared the adhesive composition of 18 mass % of active ingredient concentration, respectively.

[0272] The details of each component used are as follows.

[0273] - Modified polyolefin-based resin (A): manufactured by Mitsui Chemicals Co., Ltd., product name "UNISTOLE H-200", acid-modified α-olefin polymer, solid at 25°C, weight average molecular weight (Mw)=47,000.

[0274] · Thermosetting component (B):

[0275] Polyfunctional epoxy compound (1): manufactured by Mitsubishi Chemical Corporation, product name "YX8034", hydrogenated bisphenol A diglycidyl ether, epoxy equivalent = 270 g / eq, weight average molecular weight (Mw) = 3,200.

[0276] Polyfunctional epoxy compound (2): manufactured by Mitsubishi Chemical Corporation, product name "YX8000", hydroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com