Heating battery module

A battery module and heating chip technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of poor heating uniformity, small contact area, poor process operability, etc., and achieve consistent contact area and heating uniformity. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

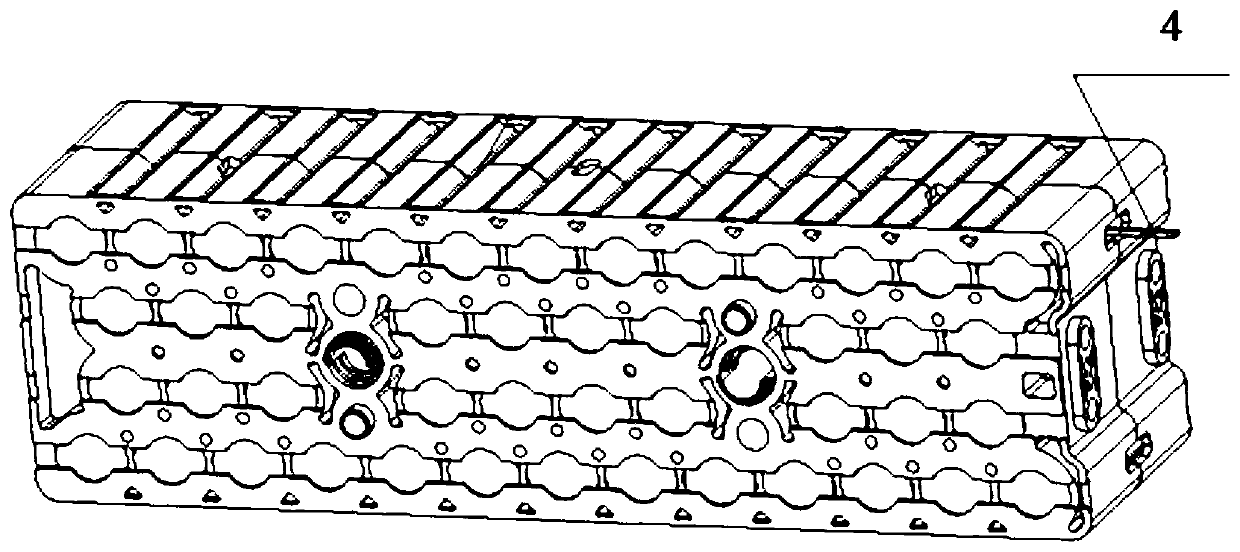

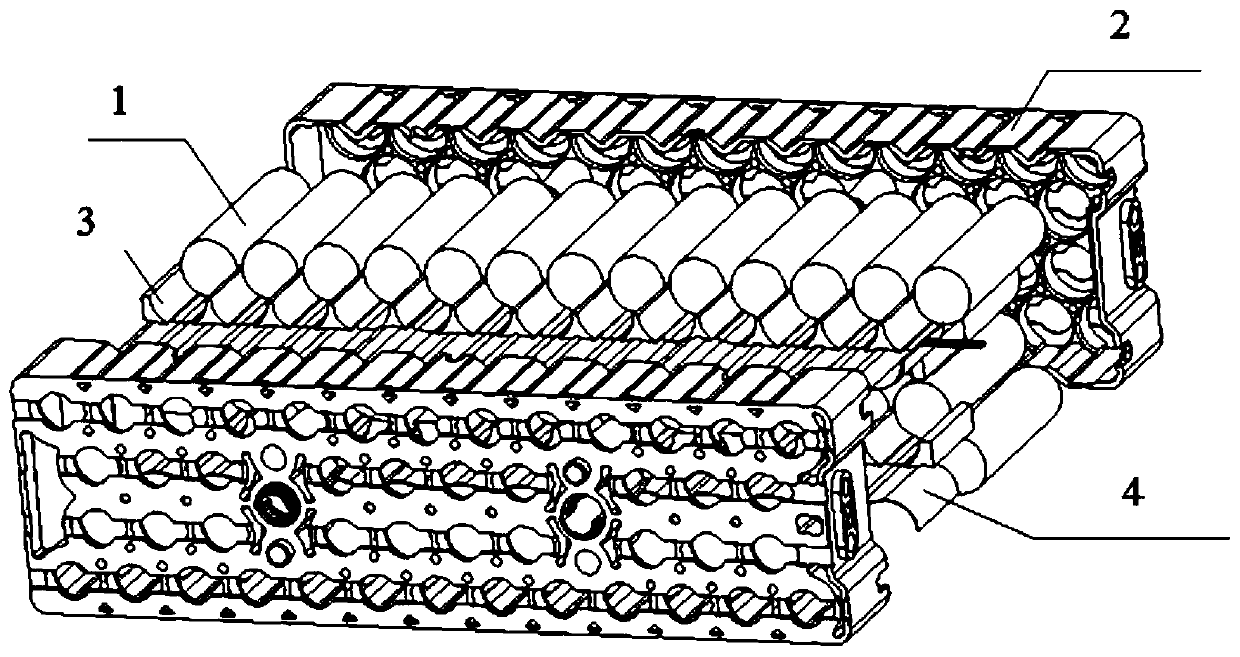

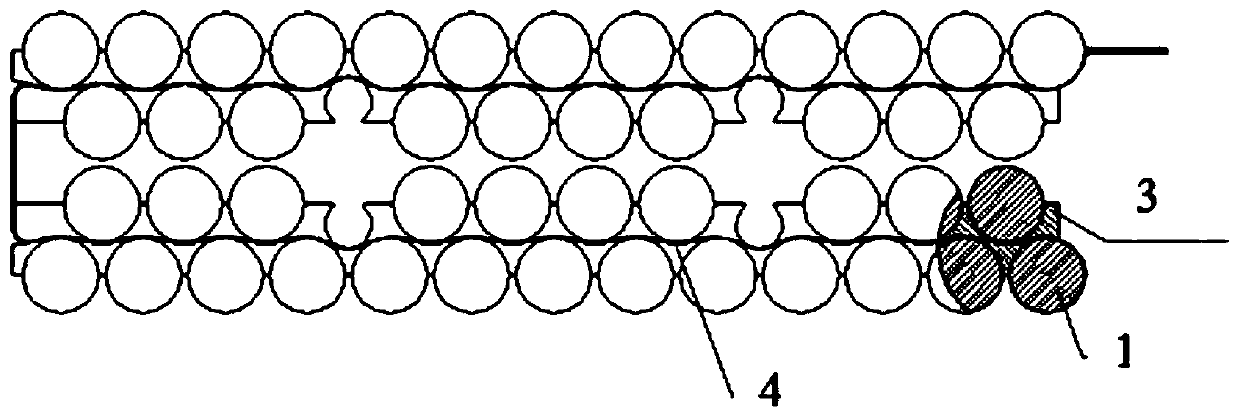

[0017] The heating battery module of the present invention includes a battery cell 1, a matching bracket 2 installed on the front and rear ends of the battery cell 1 and fixing the battery cell 1, a silica gel block 3 and a PI type heating sheet 4, wherein the battery cell 1 is cylindrical , the cylindrical surface of the cell 1 is closely attached to the PI type heating sheet 4, the silica gel block 3 is arranged in parallel with the cell 1 and the silica gel block 3 is closely attached to the PI type heating sheet 4.

[0018] Among them, the PI type heating plate 4 has a three-layer structure, the middle is a metal heating plate 5, usually made of nickel-chromium alloy, copper foil and other materials; the outer two layers are PI (polyimide) film 6, which is an organic polymer Material, high temperature resistance, long-term use temperature range -200 ~ 300 ℃, and go...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com