A kind of formation method of lithium ion battery with nickel cobalt lithium manganate positive electrode

A technology of nickel-cobalt lithium manganese oxide and lithium-ion batteries, which is applied in the field of formation of lithium-ion batteries, can solve the problems of cycle life maintenance rate to be improved, inability to release lithium ions, and large energy loss, etc., and achieve cycle life improvement and improvement effect , Increase the effect of lithium ion content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

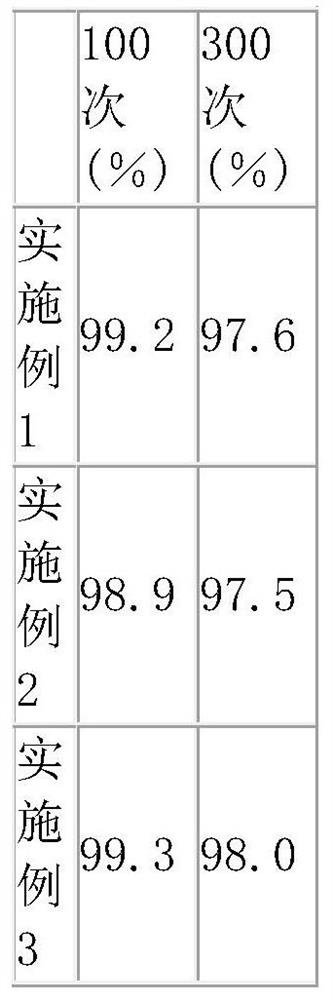

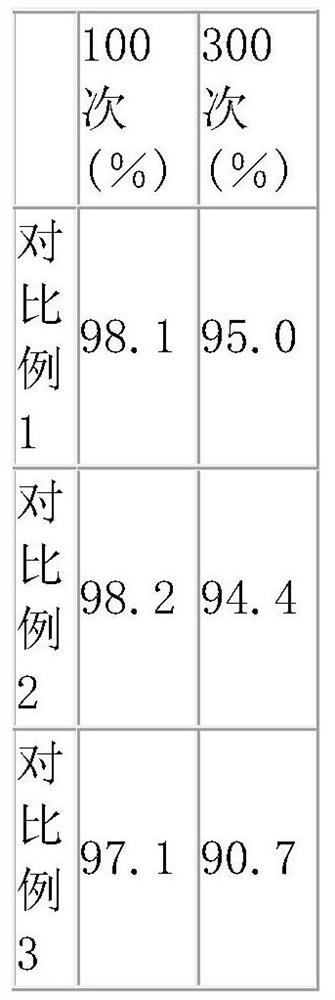

Embodiment 1

[0036] Form into step a:

[0037] 1) A graphite electrode is used as the positive electrode, and a metal lithium electrode is used as the negative electrode, which is placed in the electrolyte a to form a pre-embedded lithium battery;

[0038] 2), the battery is pulse-discharged, the discharge voltage is cut off at 0.08V, the pulse discharge is a pulse current of 0.1C, and the discharge time is 60 seconds with an interval of 2 seconds;

[0039] 3), let stand for 1h;

[0040] 4) Charge the battery at a constant voltage, the charging voltage is 3V, and stop when the charging current is lower than 0.01C;

[0041] 5), the battery is pulse-discharged again, and the discharge voltage is cut off at 0.08V to obtain a graphite negative electrode pre-charged with lithium. The pulse discharge is a pulse current of 0.1C, and the discharge time is 60 seconds with an interval of 2 seconds;

[0042] Formation step b:

[0043] 1) Assembling the nickel-cobalt lithium manganese oxide positiv...

Embodiment 2

[0053] Form into step a:

[0054] 1) A graphite electrode is used as the positive electrode, and a metal lithium electrode is used as the negative electrode, which is placed in the electrolyte a to form a pre-embedded lithium battery;

[0055] 2), the battery is pulse-discharged, the discharge voltage is cut off at 0.08V, the pulse discharge is a pulse current of 0.5C, and the discharge time is 300 seconds with an interval of 5 seconds;

[0056] 3), let stand for 1h;

[0057] 4) Charge the battery at a constant voltage, the charging voltage is 3V, and stop when the charging current is lower than 0.01C;

[0058] 5), the battery is pulse-discharged again, and the discharge voltage is cut off at 0.08V to obtain a graphite negative electrode pre-charged with lithium. The pulse discharge is a pulse current of 0.5C, and the discharge time is 300 seconds with an interval of 5 seconds;

[0059] Formation step b:

[0060] 1) Assembling the nickel-cobalt lithium manganese oxide posit...

Embodiment 3

[0070] Form into step a:

[0071] 1) A graphite electrode is used as the positive electrode, and a metal lithium electrode is used as the negative electrode, which is placed in the electrolyte a to form a pre-embedded lithium battery;

[0072] 2), the battery is pulse-discharged, the discharge voltage is cut off at 0.08V, the pulse discharge is a pulse current of 0.2C, and the discharge time is 100 seconds with an interval of 3 seconds;

[0073] 3), let stand for 1h;

[0074] 4) Charge the battery at a constant voltage, the charging voltage is 3V, and stop when the charging current is lower than 0.01C;

[0075] 5), the battery is pulse-discharged again, and the discharge voltage is cut off at 0.08V to obtain a graphite negative electrode pre-charged with lithium. The pulse discharge is a pulse current of 0.2C, and the discharge time is 100 seconds with an interval of 3 seconds;

[0076] Formation step b:

[0077] 1) Assembling the nickel-cobalt lithium manganese oxide posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com