Preparation method and use method of amorphous vanadium oxide/carbon fiber material for lithium-sulfur battery

A carbon fiber material, lithium-sulfur battery technology, applied in the direction of secondary battery repair/maintenance, secondary battery, electrochemical generator, etc., can solve the problem of reducing the energy density of the electrode, and achieve the effect of performance improvement and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

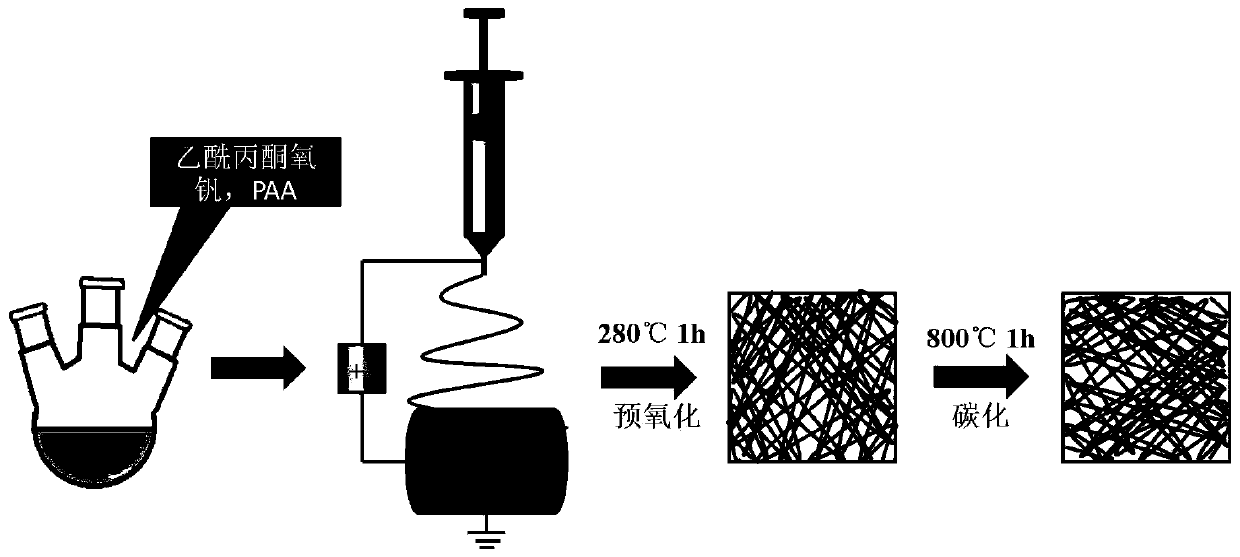

[0039] A method for preparing an amorphous vanadium oxide / carbon fiber material for lithium-sulfur batteries, comprising the steps of:

[0040] Step 1. Weigh vanadyl acetylacetonate, dimethylformamide, 4-4 diaminodiphenyl ether and pyromellitic anhydride of a certain quality respectively according to a certain solid-liquid ratio, and set aside;

[0041] Step 2. Add the dimethylformamide to the vanadyl acetylacetonate weighed in step 1, stir magnetically for a certain period of time, and after fully dissolving, add the 4-4 diaminodiphenyl ether , after ultrasonication for a certain period of time, adding the pyromellitic anhydride in stages under the condition of mechanical stirring, and stirring for a certain period of time to obtain a precursor solution for use;

[0042] Step 3. Electrospinning the precursor solution prepared in step 2 to obtain polymer fibers for use;

[0043] Step 4, place the polymer fiber prepared in step 3 in a tube furnace for heat treatment at 5°C min...

specific Embodiment approach 2

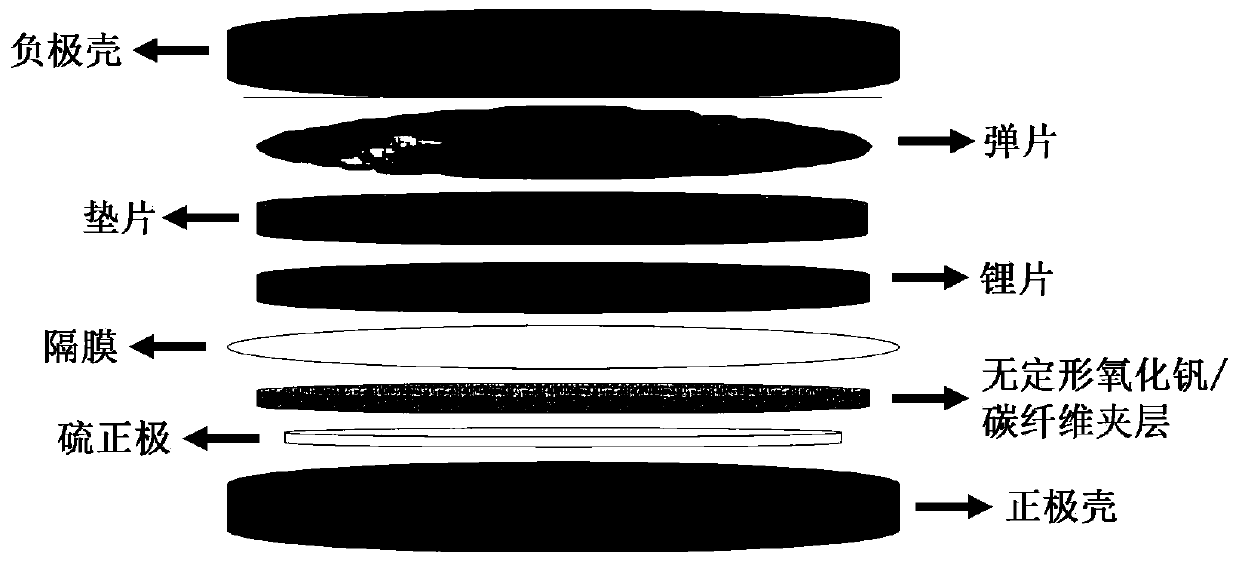

[0054] According to the method for preparing an amorphous vanadium oxide / carbon fiber material for lithium-sulfur batteries described in Embodiment 1, the method for using the amorphous vanadium oxide / carbon fiber material for lithium-sulfur batteries is prepared, The described amorphous vanadium oxide / carbon fiber material for lithium-sulfur batteries is made into a circular interlayer, which is placed between the diaphragm and the positive electrode of the lithium-sulfur battery.

[0055] A method for preparing an amorphous vanadium oxide / carbon fiber material for lithium-sulfur batteries described in this embodiment, and a method for using an amorphous vanadium oxide / carbon fiber material for lithium-sulfur batteries, said The preparation method of the positive electrode is to use sublimed sulfur powder as the positive electrode active material, Super-P as the conductive agent, and PVDF as the binder. After manual grinding in a mortar for 20 minutes, add 5% NMP solution, and...

specific Embodiment approach 3

[0065] A method for preparing an amorphous vanadium oxide / carbon fiber material for lithium-sulfur batteries, comprising the steps of:

[0066] Step 1. Weigh vanadyl acetylacetonate, dimethylformamide, 4-4 diaminodiphenyl ether and pyromellitic anhydride of a certain quality respectively according to a certain solid-liquid ratio, and set aside;

[0067] Step 2. Add the dimethylformamide to the vanadyl acetylacetonate weighed in step 1, stir magnetically for a certain period of time, and after fully dissolving, add the 4-4 diaminodiphenyl ether , after ultrasonication for a certain period of time, adding the pyromellitic anhydride in stages under the condition of mechanical stirring, and stirring for a certain period of time to obtain a precursor solution for use;

[0068] Step 3. Electrospinning the precursor solution prepared in step 2 to obtain polymer fibers for use;

[0069] Step 4, place the polymer fiber prepared in step 3 in a tube furnace for heat treatment at 5°C min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com