Lithium-philic heteroatom and metal oxide co-doped three-dimensional fiber frame lithium battery negative electrode and preparation

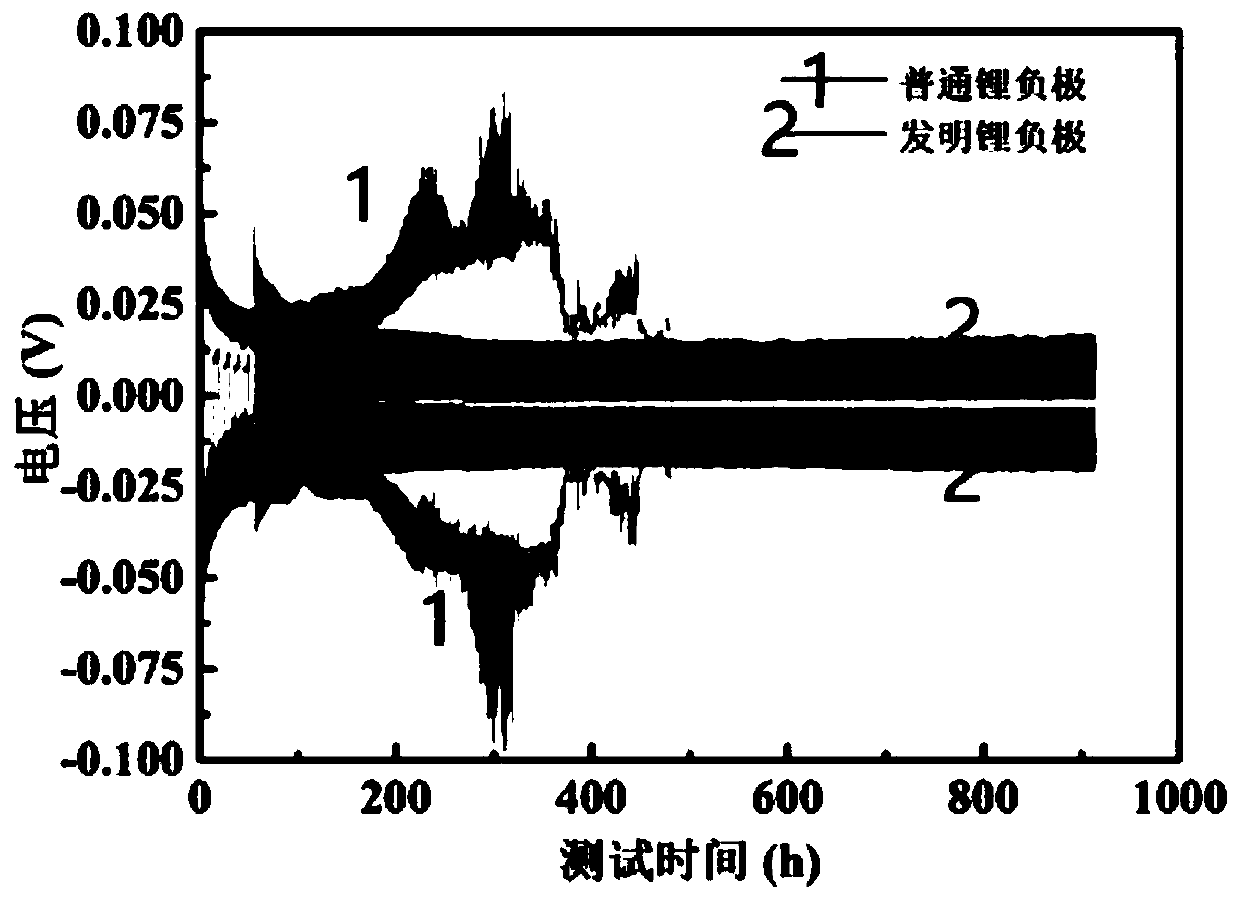

A technology of heteroatoms and oxides, applied in the field of energy storage devices, can solve problems such as lithium dendrite growth, and achieve the effect of avoiding lithium dendrites and improving long-cycle stability and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of stable and safe lithium anode

[0036] Accurately weigh out 5.0g of gelatin and dissolve it in 45.0g of solvent (the mass ratio of water to trifluoroethanol is 1:1), then divide the solvent into two parts, and add 0.356g of acetic acid dihydrate to one part. Zinc, add 0.136g lithium hydroxide monohydrate to the other portion, and after stirring uniformly, add the solution containing lithium hydroxide monohydrate to the solution containing zinc acetate dihydrate dropwise and stir while adding dropwise. The total reaction time is half an hour. Afterwards, it is spun into a fiber film on copper foil using an electrospinning machine (the film thickness is 0.02mm). The technical parameters of electrospinning in step (2) are: advancement amount 0.01mL / min, translation speed 0.08cm / min . Let it stand at room temperature for 24 hours.

[0037] The above modified copper foil is heated in a tube furnace filled with nitrogen. The temperature range of the heating pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com