Method for identifying insulator defects by pruning YOLOv3 with small on-site sample size

A technology of insulators and sample size, applied in neural learning methods, character and pattern recognition, optical test flaws/defects, etc., can solve the problems of missed judgment and misjudgment of manual inspection pictures, inability to always use learning results, and cumbersome screening work. , to achieve the effect of optimizing lightweight performance, avoiding precision degradation, and reducing hardware requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

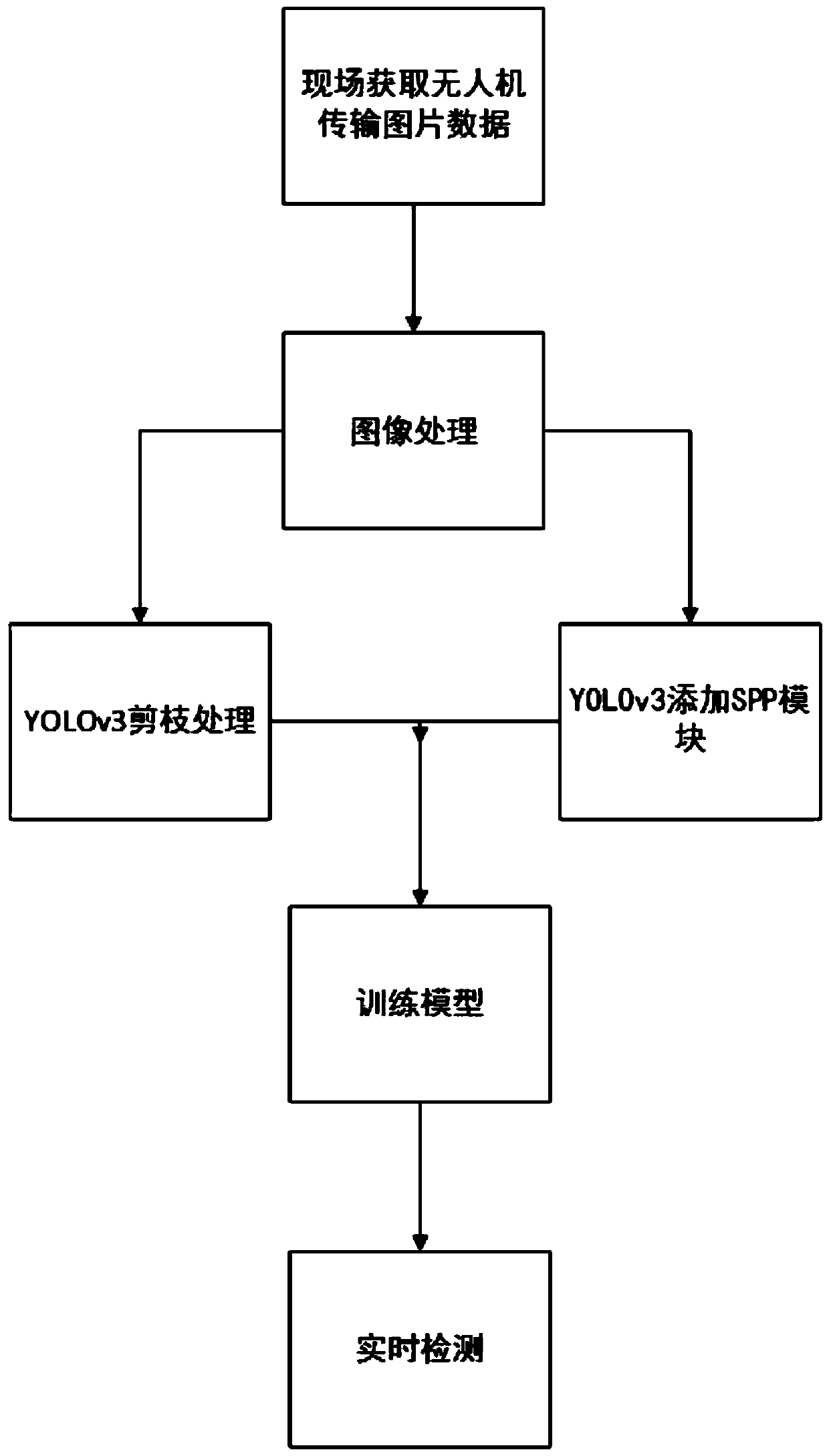

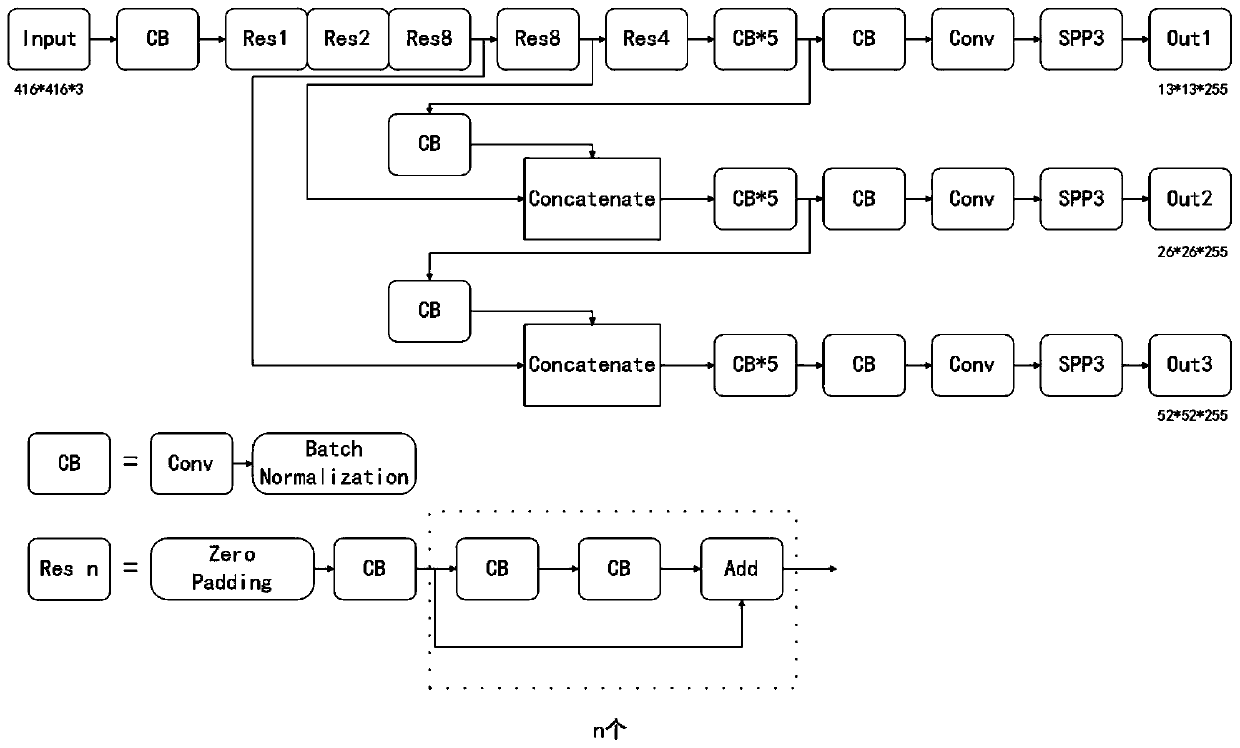

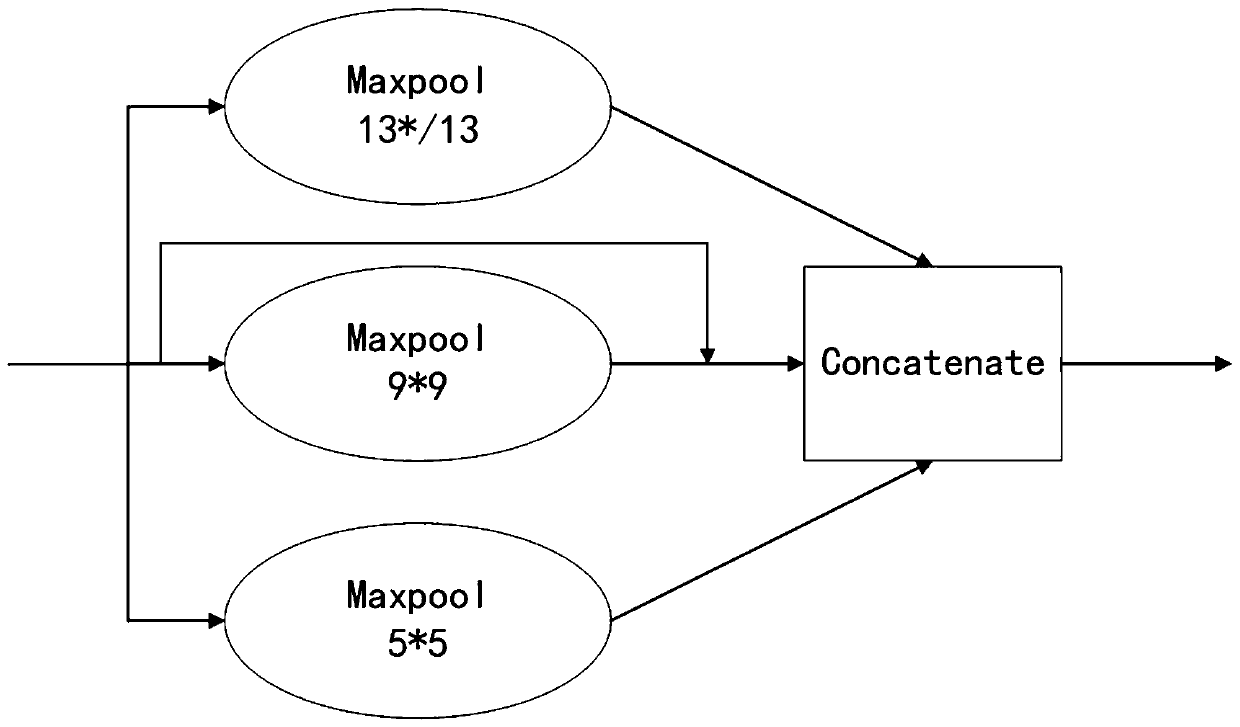

[0033] As shown in the figure, a YOLOv3 pruning method suitable for identifying insulator defects with a small sample size on site, the specific steps are:

[0034] Step 1: According to the real-time transmission of image data according to the drone inspection, obtain the insulator image and the corresponding XML label data, and change it to TXT format according to the file characteristics of Darknet-53. The labeling tool LabelImg used is a visual image calibration Tool, the data set required by the YOLOv3 algorithm needs to use this tool to calibrate the target in the image and generate an XML file that follows the format of PASCAL VOC;

[0035] Step 2: Carry out pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com