Electric vehicle and front cabin structure thereof

A technology for electric vehicles and front apron, which is applied to the substructure, vehicle parts, bumpers and other directions to achieve the effects of good mechanical performance, good safety performance and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

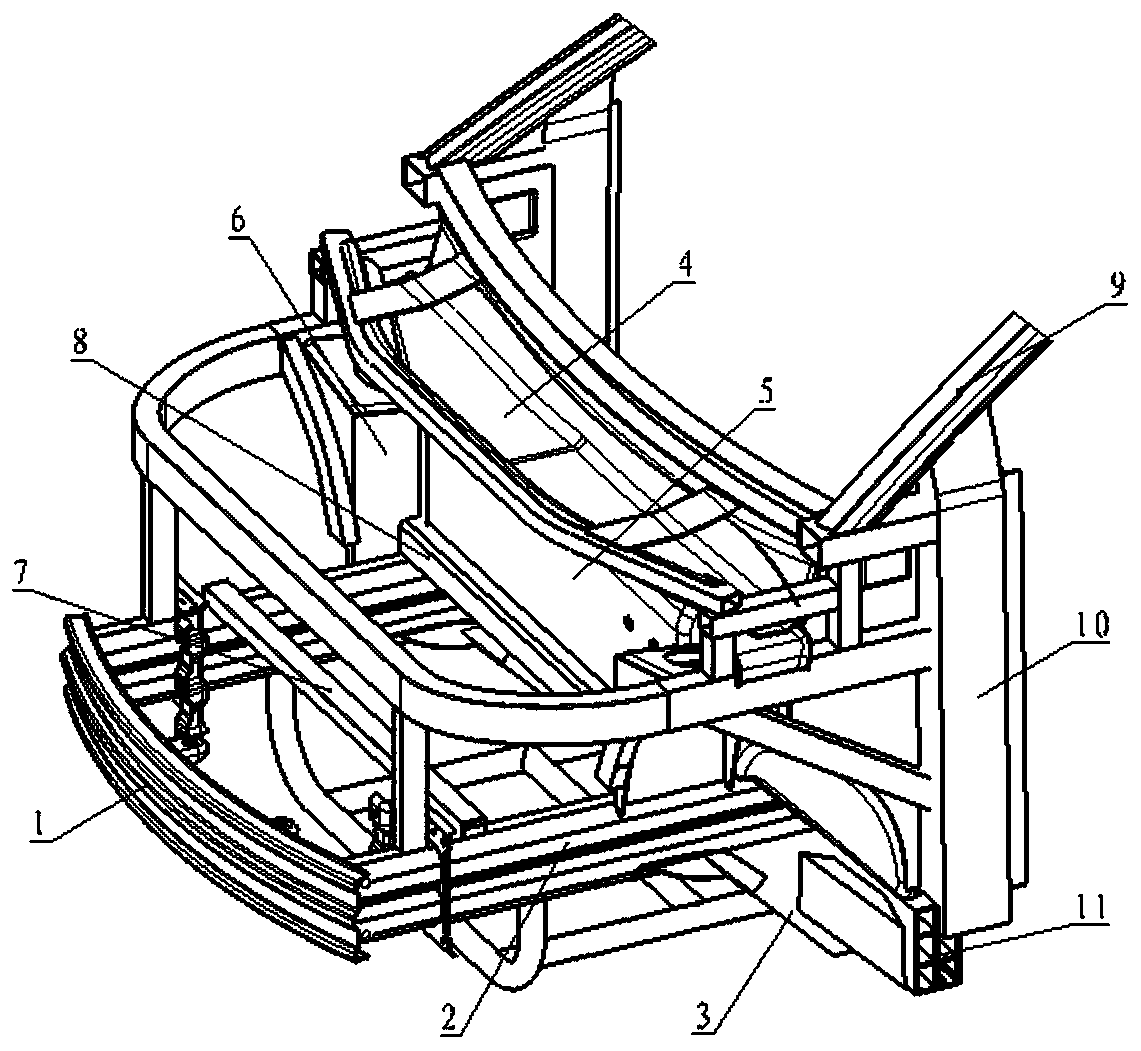

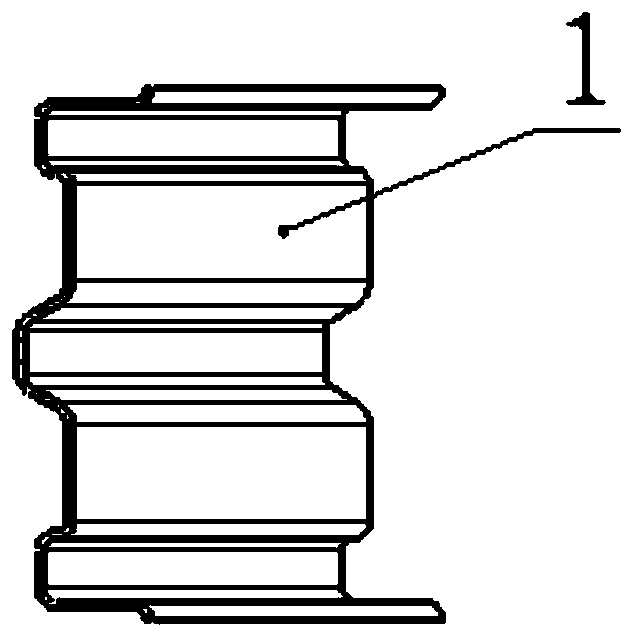

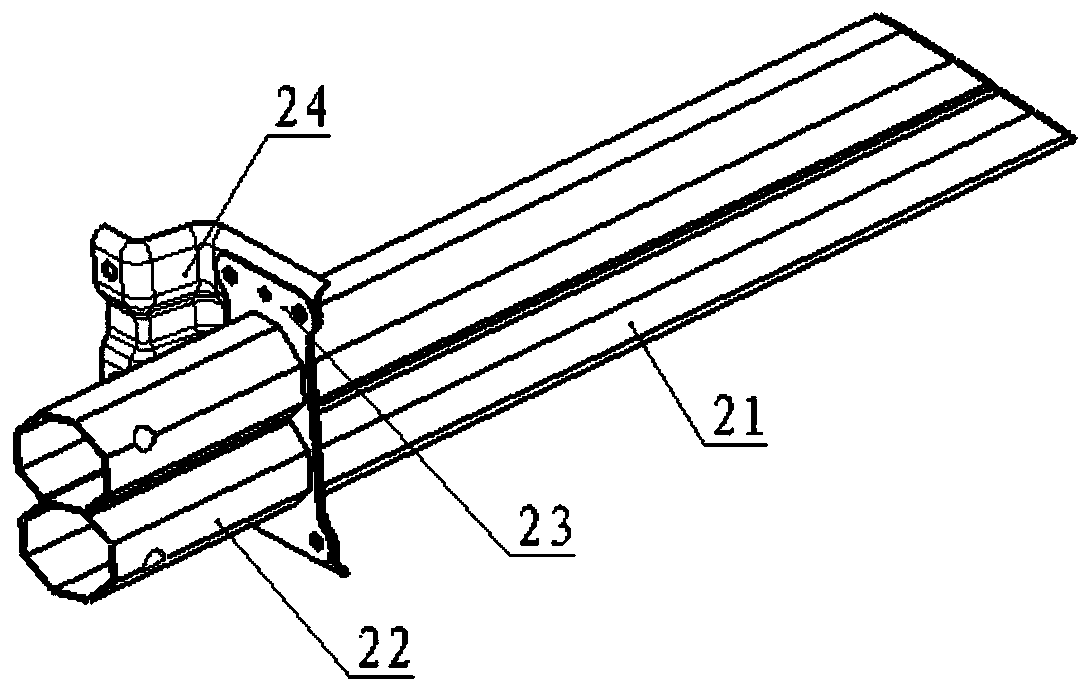

[0033] like figure 1 As shown, the front cabin structure of the electric vehicle of the present invention is symmetrical about the zx plane of the vehicle, including a front anti-collision beam 1, a front longitudinal beam assembly 2, an oblique support beam assembly 3, a running water tank 4, a dash panel 5, The shock tower 6, the first front beam 7 and the second front beam 8; the two ends of the front anti-collision beam 1 are respectively welded to the front longitudinal beam assembly 2, and the end of the front longitudinal beam assembly 2 far away from the front anti-collision beam 1 is connected to the front The coaming panel 5 is attached, and the dash panel 5 is also attached to the oblique support beam assembly 3. The oblique support beam assembly 3 is located below the front longitudinal beam assembly 2, and the oblique support beam assembly 3 is connected to the front longitudinal beam assembly The beam assembly 2 is connected by surface welding, the upper part of ...

Embodiment 2

[0038] An electric vehicle includes the front cabin structure in Embodiment 1. The structure and beneficial effects of the front cabin structure have been described in detail in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com