A zero-value insulator infrared detection method

A zero-value insulator, infrared detection technology, applied in the direction of using optical methods for testing, measuring electricity, measuring devices, etc., to reduce workload, improve inspection efficiency and line safety operation level, and reduce insulator inspection workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

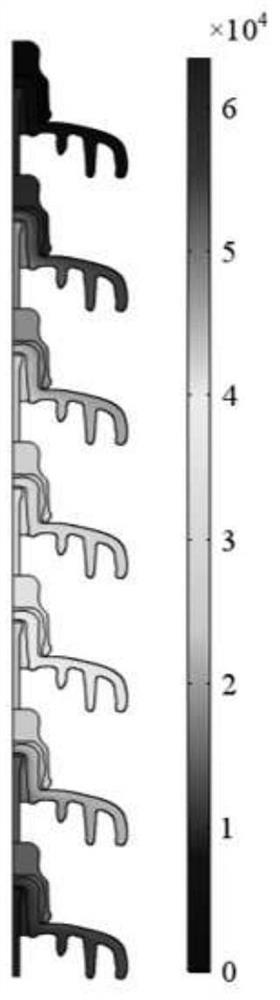

Image

Examples

Embodiment Construction

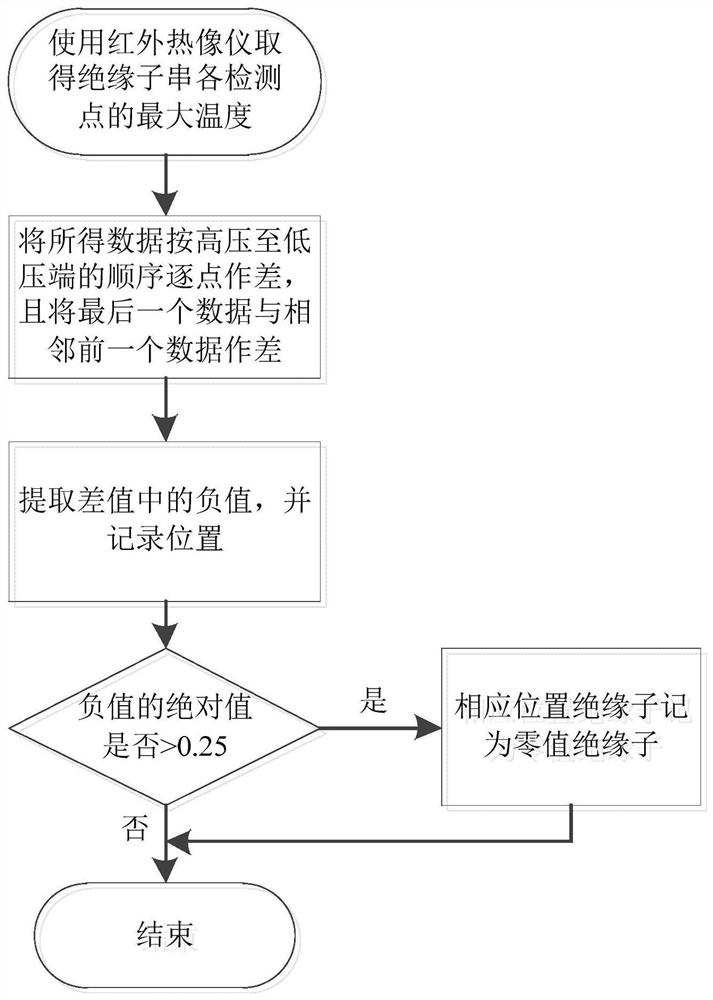

[0045] A zero-value insulator infrared detection method, comprising the following steps:

[0046] Step 1: Set the zero-value insulator detection conditions, including the pollution degree of the insulator surface, the relative humidity of the environment, and the position of the zero-value insulator in the insulator string;

[0047] Step 2: Then select the same position of each insulator in the insulator string as the infrared detection point;

[0048] Step 3: Use an infrared thermal imager to obtain the maximum temperature of each infrared detection point of the insulator string;

[0049] Step 4: Make a point-by-point difference of the obtained maximum temperature data of each infrared detection point in the order from the high-voltage end to the low-voltage end, and make a difference between the last data and the adjacent previous data;

[0050] Step 5: extract the negative value in the difference, and record the position;

[0051] Step 6: Judging the absolute value of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com