Ceramic material laser processing device and method

A laser processing method and technology of ceramic materials, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of large taper, easy edge collapse of hole wall, and small depth-to-diameter ratio, so as to disperse heat accumulation and improve laser utilization rate, reducing the effect of temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

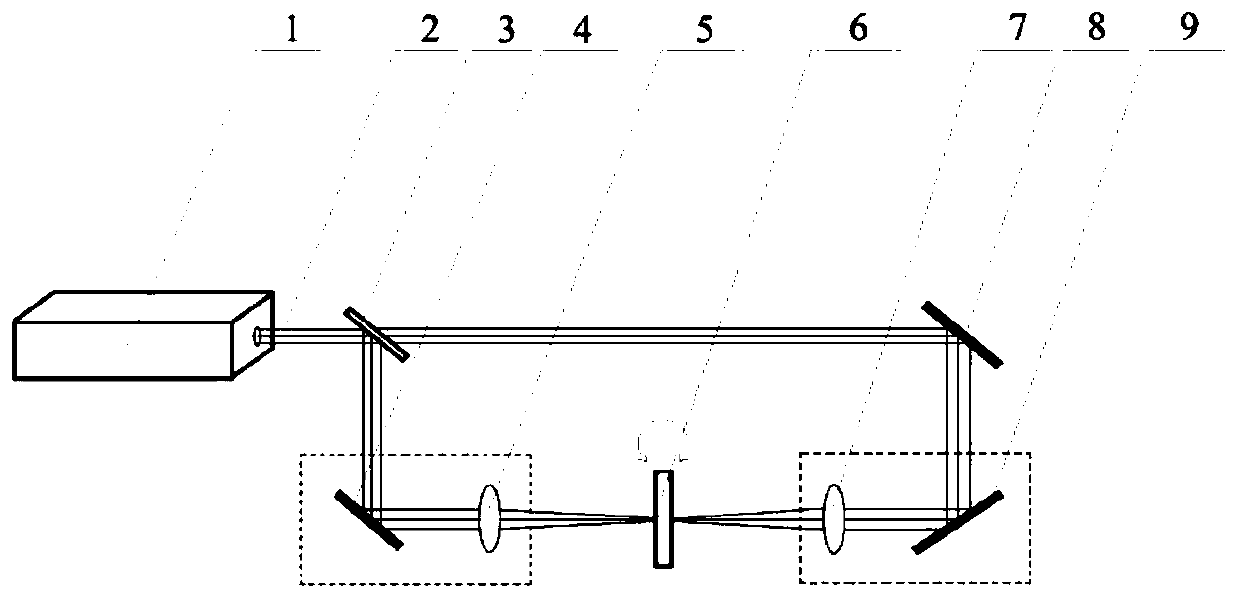

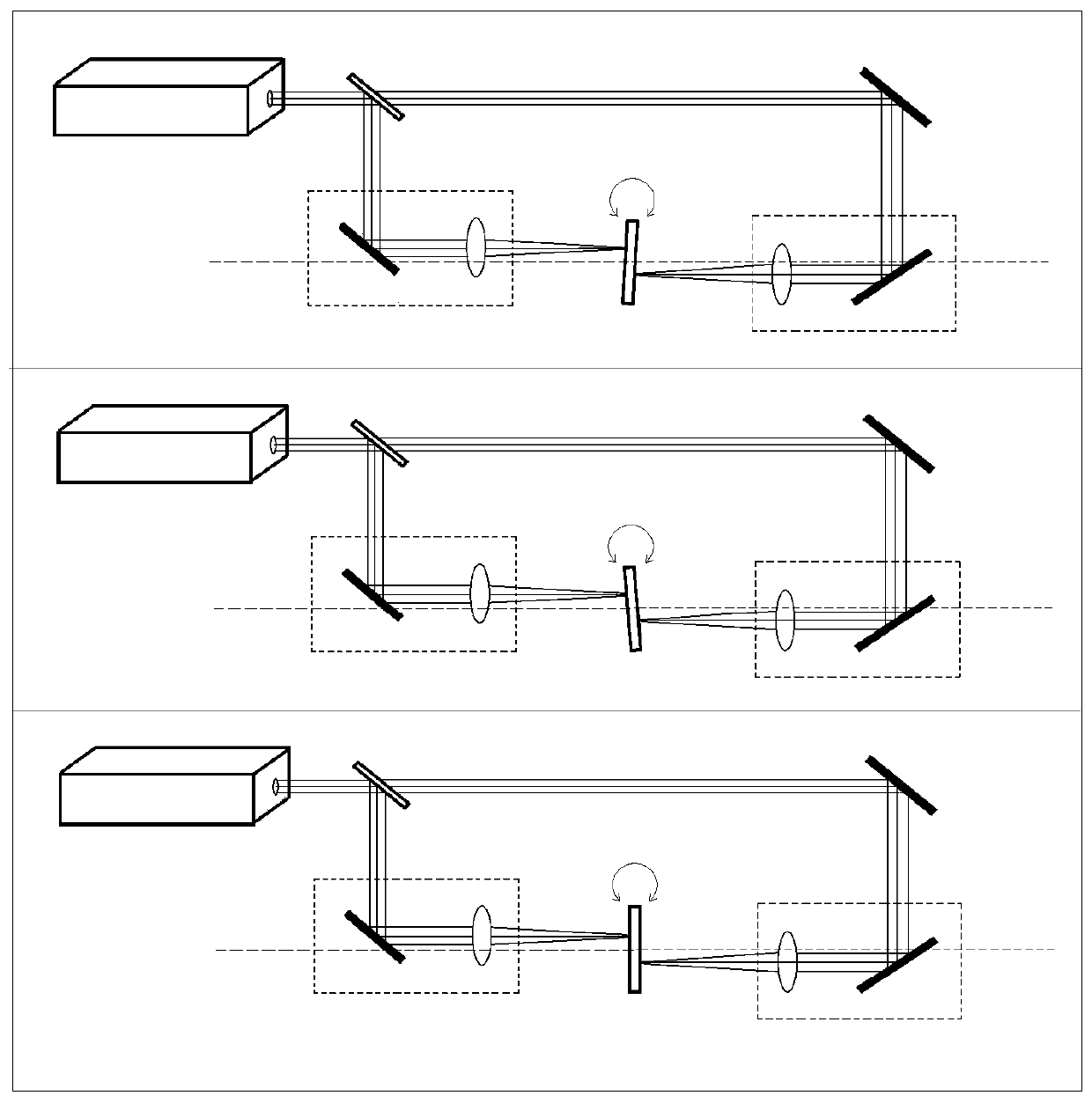

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0044] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings. However, those skilled in the art know that the present invention is not limited to the drawings and the following embodiments.

[0045]A ceramic material laser processing device and method of the present invention, for laser drilling of ceramic materials, solves the existing problems of small depth-to-diameter ratio, large taper, and easy edge collapse of the hole wall, etc., and realizes high-quality drilling of ceramic materials. To meet the needs of ultra-high frequency communication electronics industry for micro-processing of ceramic packaging substrates. The depth-to-diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com