A kind of detection method of grounding current of polysilicon reduction furnace power supply system

A grounding current and power system technology, applied in chemical instruments and methods, measuring current/voltage, silicon compounds, etc., can solve problems such as inability to adapt to the adjustment of the reduction furnace production process, incompatibility with the polysilicon production process, and inability to effectively protect the grounding point. , to achieve long-term operation, increase effective operation time, and save water and electricity resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific embodiments of the present invention will now be described. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention, that is, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those skilled in the art without creative work fall within the protection scope of the present invention.

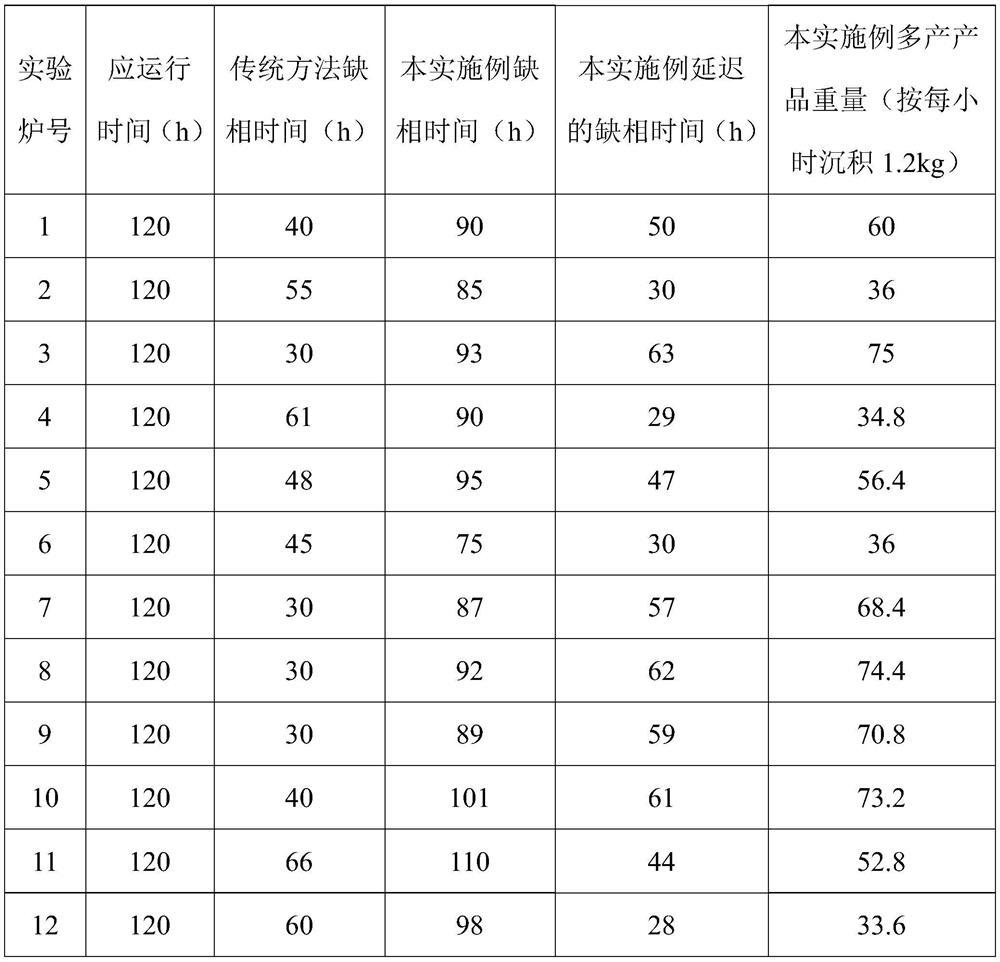

[0022] This embodiment provides a method for detecting the grounding current of a polysilicon reduction furnace power supply system by grades. According to the different constant current maintenance voltages required in different stages of silicon core growth, the maintenance voltage is set in grades, and the prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com