Reciprocating scraping type heating negative pressure separator

A scraping and separator technology, applied in separation methods, chemical instruments and methods, sulfur preparation/purification, etc., can solve the problem of low efficiency of chlorine leaching residue desulfurization or solid dehydration, complicated equipment structure, long process flow, etc. problem, to achieve the effect of increasing the conveying stroke and separation time, reducing the steam flow rate and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

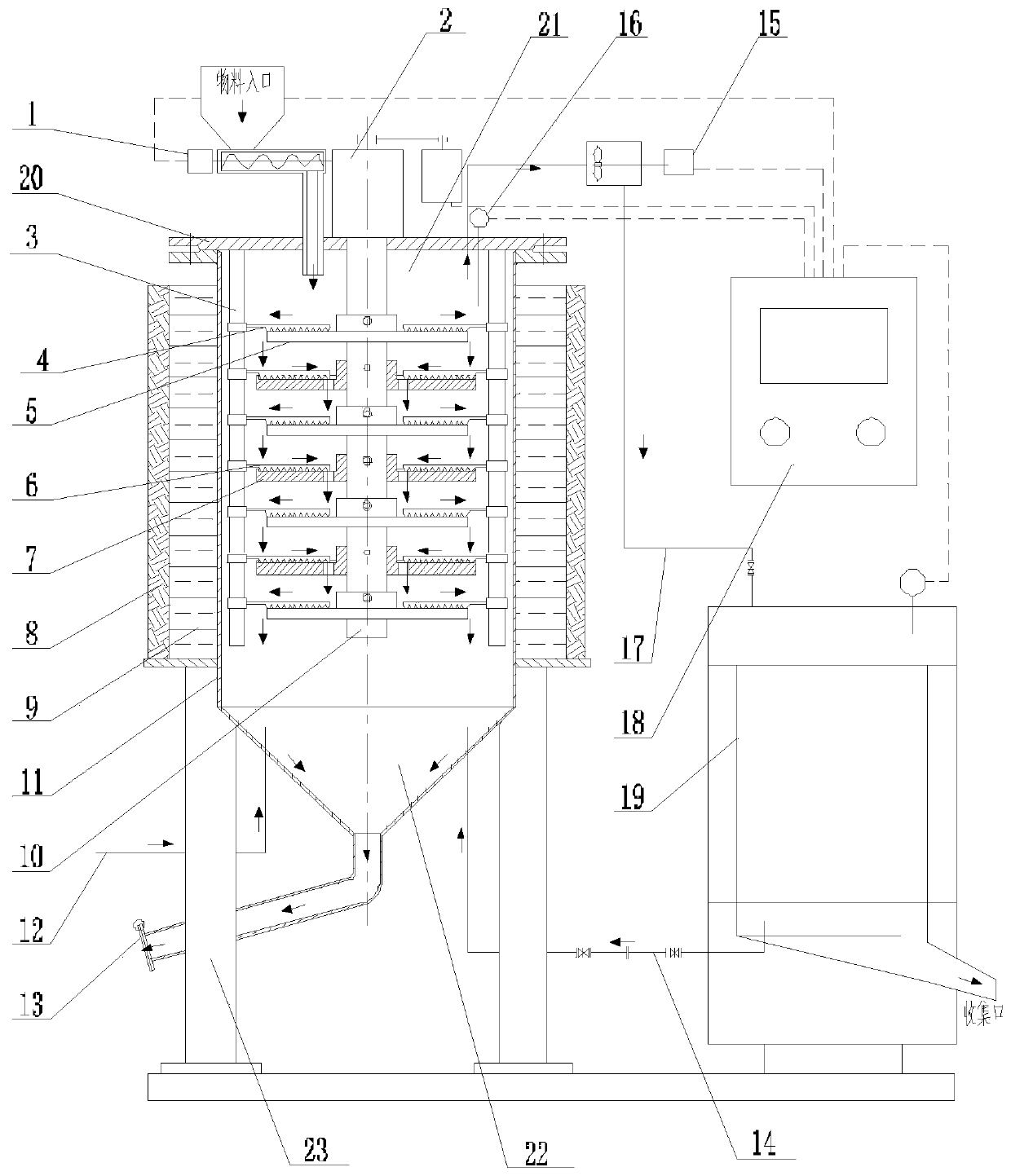

[0035] Such as Figure 1-5 As shown, the reciprocating scraping heating negative pressure separator includes a separation tank 11, a feeding device, a heating device, a reciprocating scraping device, a condenser 19 and a PLC electric control box 18, and the separation tank 11 includes a hollow cylindrical heating The tank body 21, the slag collection tank body 22 arranged at the bottom of the heating tank body 21 and integral with the heating tank body 21 and having a hollow inverted conical structure, and the top of the heating tank body 21 Tank cover 20, the feeding device is arranged on the tank cover 20 for feeding the heating tank body 21, and the heating device is circumferentially arranged on the outer wall of the heating tank body 21 for heating the heating tank body 21. The inner cavity of the tank body 21 is heated.

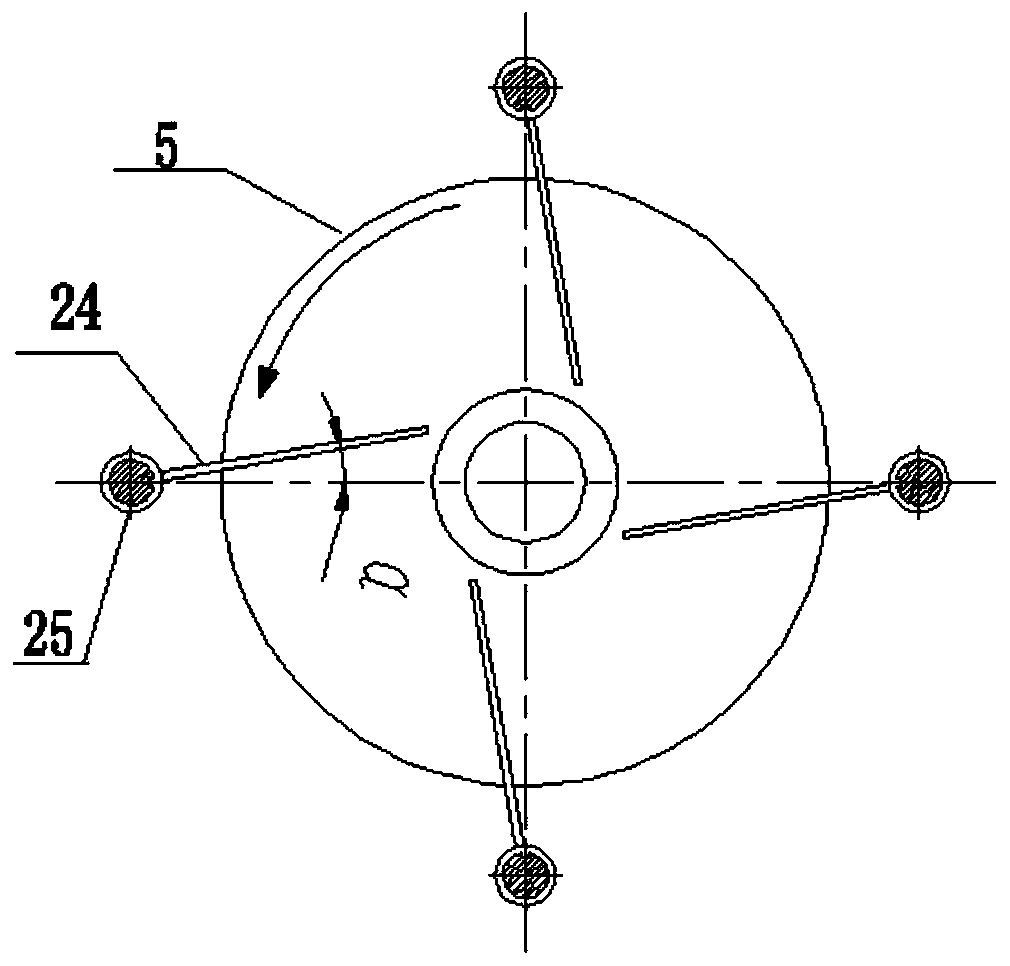

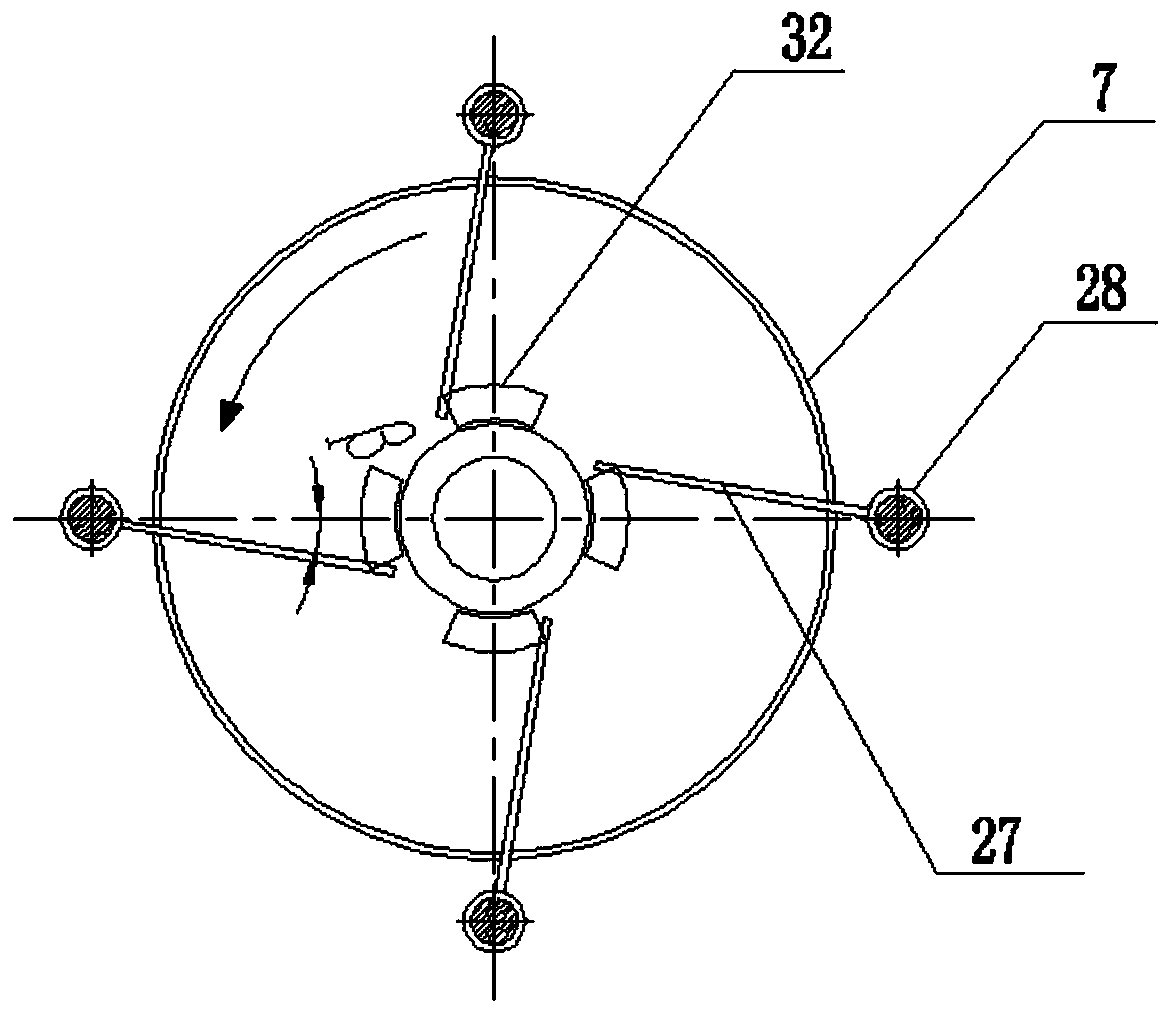

[0036]The reciprocating scraping device is located in the heating tank body 21, and includes a rotating shaft 10 coaxially arranged with the heating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com