Method for laying secondary side cable of single-stand rolling mill rectifier transformer

A rectifier transformer, single-frame technology, applied in the direction of cable laying equipment, etc., can solve problems such as cable heating, bias current, etc., to achieve the effect of ensuring safe operation of production and reducing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] There are 12 cables in the transmission bus of each transmission device on the rolling mill rectifier transformer, which are laid according to the laying method of the present invention, specifically implemented according to the following steps:

[0030] The first step is to divide the cables of the rectifier transformer into groups of three, and divide them into N groups. Each group of cables contains one U, V, and W phase-sequence cable. -1, N-2, N-3 are marked respectively in turn;

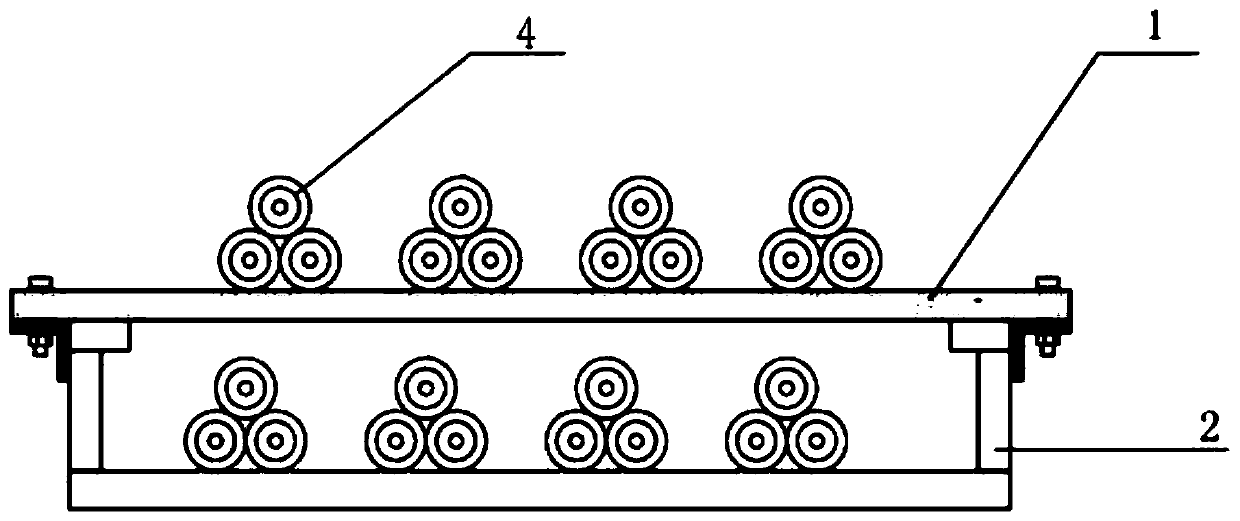

[0031] In the second step, the cables marked in the first step are divided into groups according to three different phases, grouped and tied into cable bundles, the N groups of cables divided in the first step are respectively tied, and the cross-section of the three cables in each group is Arranged in the shape of "pin";

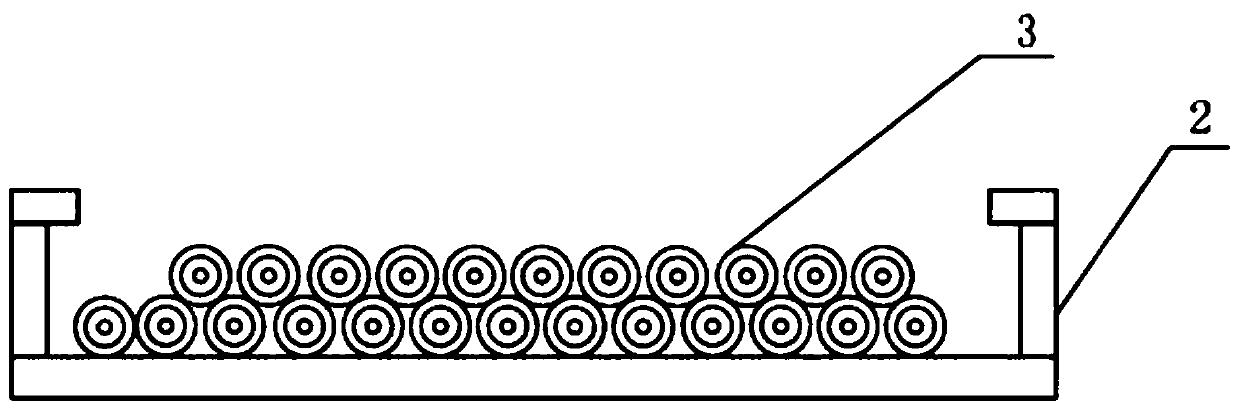

[0032] In the third step, part of the cable bundles ligated in the second step is evenly distributed on the upper surface of the existing cable bridge (2), the clear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com