Air-injection displacement oil production method for producing oil from horizontal wells by means of injecting air in vertical wells

A horizontal well and air flooding technology, applied in wellbore/well parts, production fluid, earthwork drilling and production, etc., to achieve the effects of enhanced oil recovery and oil production speed, high sweep coefficient, and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

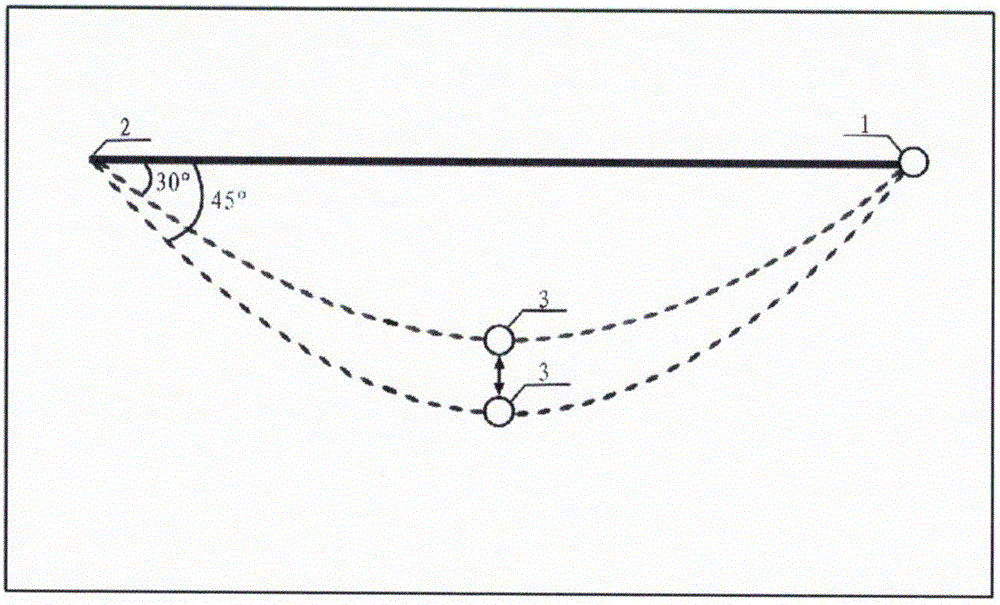

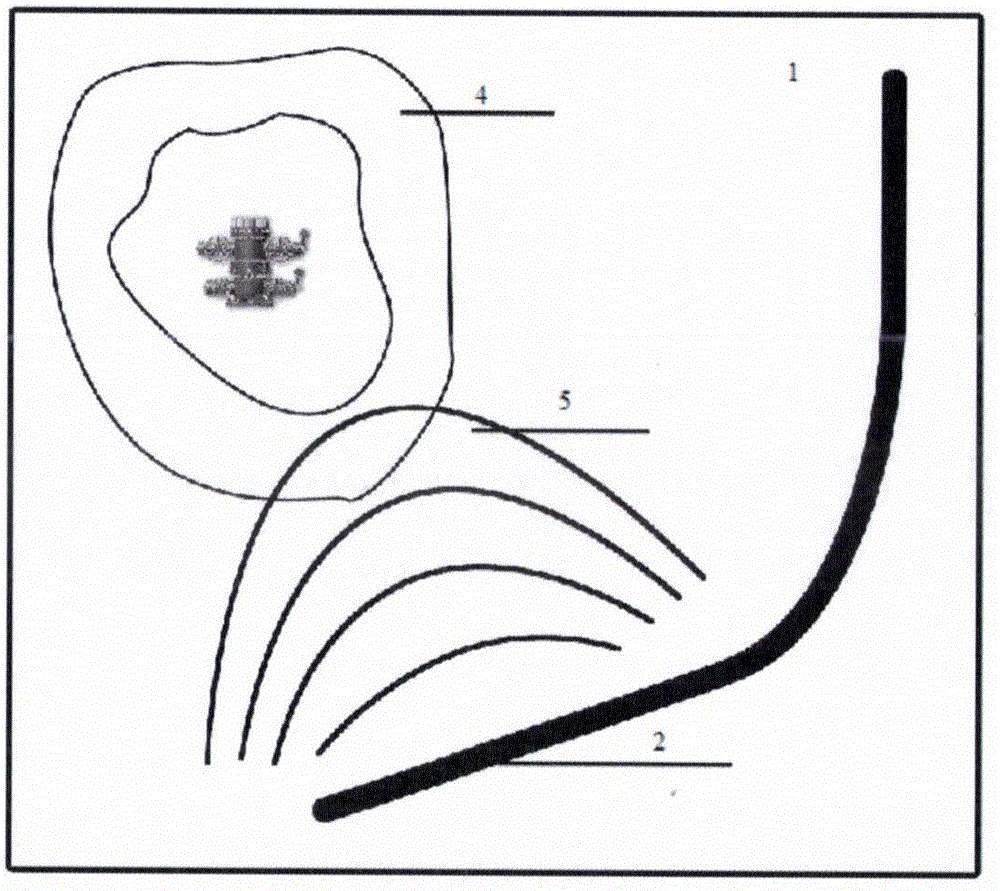

[0026] An air flooding oil production method for vertical well injection and horizontal well oil production, which is completed by the following steps, including: 1. According to the geological analysis of the oil reservoir, determine the arrangement of vertical well gas injection wells (3) and horizontal well production wells (1) to ensure that the vertical well The angle between the two ends of the horizontal section (2) of the gas injection well (3) and the production well (1) is 30°; ) at 3 meters below the bottom of the fan-shaped perforation, and the perforation density is 15 holes / m; 3. Nitrogen pressure test: connect the 800 standard square nitrogen injection pipeline to the gas injection well (3), and carry out pressure test on the oil layer through the nitrogen truck; 4. Through the steam boiler and supporting facilities, inject 120 tons of high-temperature steam into the gas injection well (3), the steam temperature is 300°C, and the steam dryness is 70%; The fan-sh...

Embodiment 2

[0028] An air flooding oil production method for vertical well injection and horizontal well oil production, which is completed by the following steps, including: 1. According to the geological analysis of the oil reservoir, determine the arrangement of vertical well gas injection wells (3) and horizontal well production wells (1) to ensure that the vertical well The angle between the two ends of the horizontal section (2) of the gas injection well (3) and the production well (1) is arranged at 36°; ) fan-shaped perforation at 6 meters below, the perforation density is 20 holes / m; 3. Nitrogen pressure test: connect the 1500 standard square nitrogen injection pipeline to the gas injection well (3), and carry out pressure test on the oil layer through the nitrogen truck; 4. Through the steam boiler and supporting facilities, inject 180 tons of high-temperature steam into the gas injection well (3), the steam temperature is 330°C, and the steam dryness is 90%; The fan-shaped perf...

Embodiment 3

[0030] An air flooding oil production method for vertical well injection and horizontal well oil production, which is completed by the following steps, including: 1. According to the geological analysis of the oil reservoir, determine the arrangement of vertical well gas injection wells (3) and horizontal well production wells (1) to ensure that the vertical well The angle between the two ends of the horizontal section (2) of the gas injection well (3) and the production well (1) is arranged at 45°; ) fan-shaped perforation is carried out at 5 meters below, and the perforation density is 18 holes / m; 3. Nitrogen pressure test: connect the 1200 standard square nitrogen injection pipeline to the gas injection well (3), and carry out pressure test on the oil layer through the nitrogen truck; 4. Through the steam boiler and supporting facilities, inject 150 tons of high-temperature steam into the gas injection well (3), the steam temperature is 320°C, and the steam dryness is 80%; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com