Batch annealing process-based cold rolled weathering resistant steel and manufacturing method thereof

A bell-type annealing and manufacturing method technology, which is applied in the field of metal materials, can solve problems such as buckling and easy bonding, and achieve the effects of improved formability, excellent atmospheric corrosion resistance, and excellent welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be described below through specific examples.

[0035] In order to realize the cold-rolled weather-resistant steel plate mentioned in this patent, the examples are as follows:

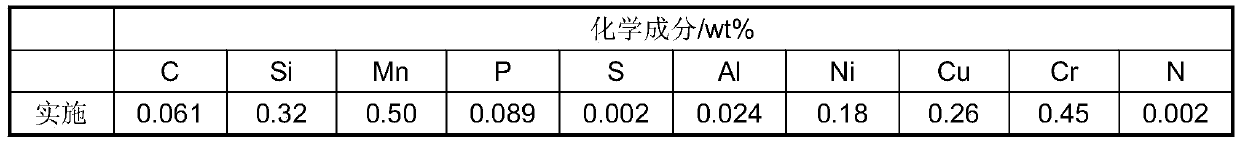

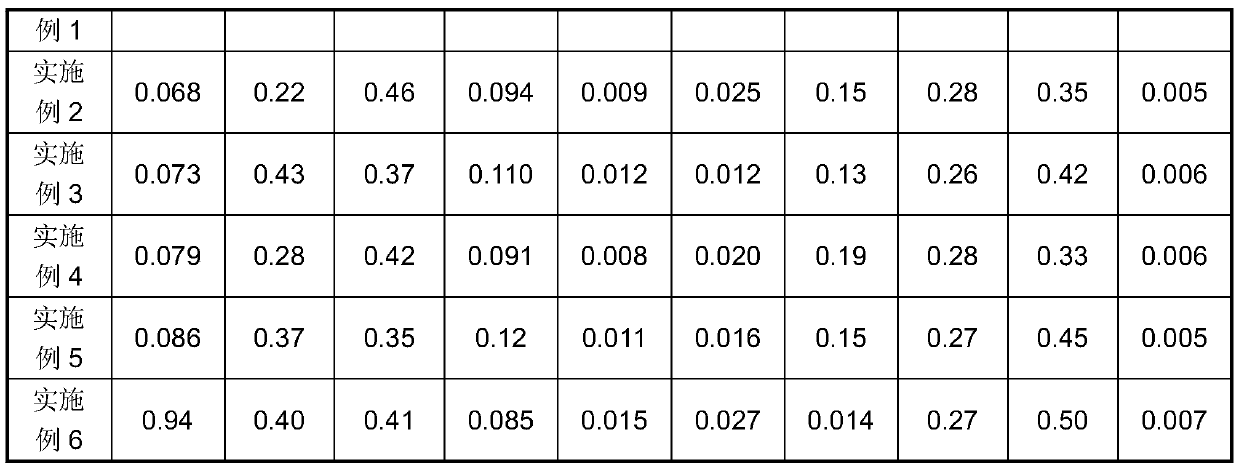

[0036] Table 1 is the chemical composition list of each group of embodiments, and the rest are inevitable impurities and Fe.

[0037] The chemical composition table of each group of embodiment of table 1

[0038]

[0039]

[0040] After continuous casting of the molten steel in each group of examples in the table, seven-stand continuous hot rolling, pickling, five-stand full-six-high continuous cold rolling, electrolytic degreasing, bell annealing, wet tempering and other processes, the main process parameters are shown in the table 2. The final properties are shown in Table 3.

[0041] Table 2 Production Process Parameters

[0042]

[0043] The performance of each example is shown in Table 3.

[0044] The mechanical properties o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com