Electric furnace steelmaking method and system

An electric furnace steelmaking and electric furnace technology, which is applied to electric furnaces, furnaces, furnace types, etc., can solve the problems of increased steelmaking costs, difficulty in penetrating the slag layer into molten steel, and a large amount of injection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

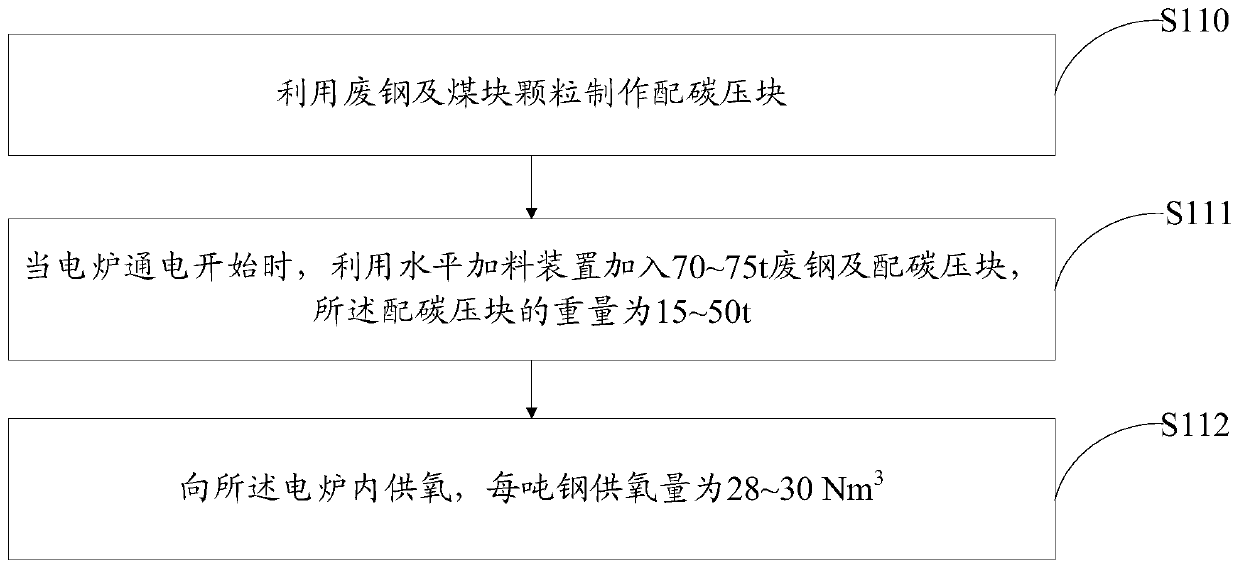

[0040] This embodiment provides a method for electric furnace steelmaking, such as figure 1 As shown, the method includes:

[0041] S110, using scrap steel and coal particles to make carbon briquettes;

[0042] In this embodiment, in order to increase the feeding speed of the electric furnace, the carbon briquettes are first made of scrap steel and coal particles, which specifically include:

[0043] placing the coal lump particles inside the steel scrap, so that the scrap steel wraps the coal lump particles;

[0044] Using a briquetting machine to press the steel scrap wrapped with the coal particles into the carbon-combined briquette.

[0045] Among them, the carbon content of the coal block formed by the coal particles in the carbon briquette is ≥75%, and the weight of each carbon briquette is 70-100kg; the coal content in each carbon briquette is 10-20kg , the length, width and height of each carbon briquetting block are 200mm×300mm×300mm.

[0046] Here, the coal block...

Embodiment 2

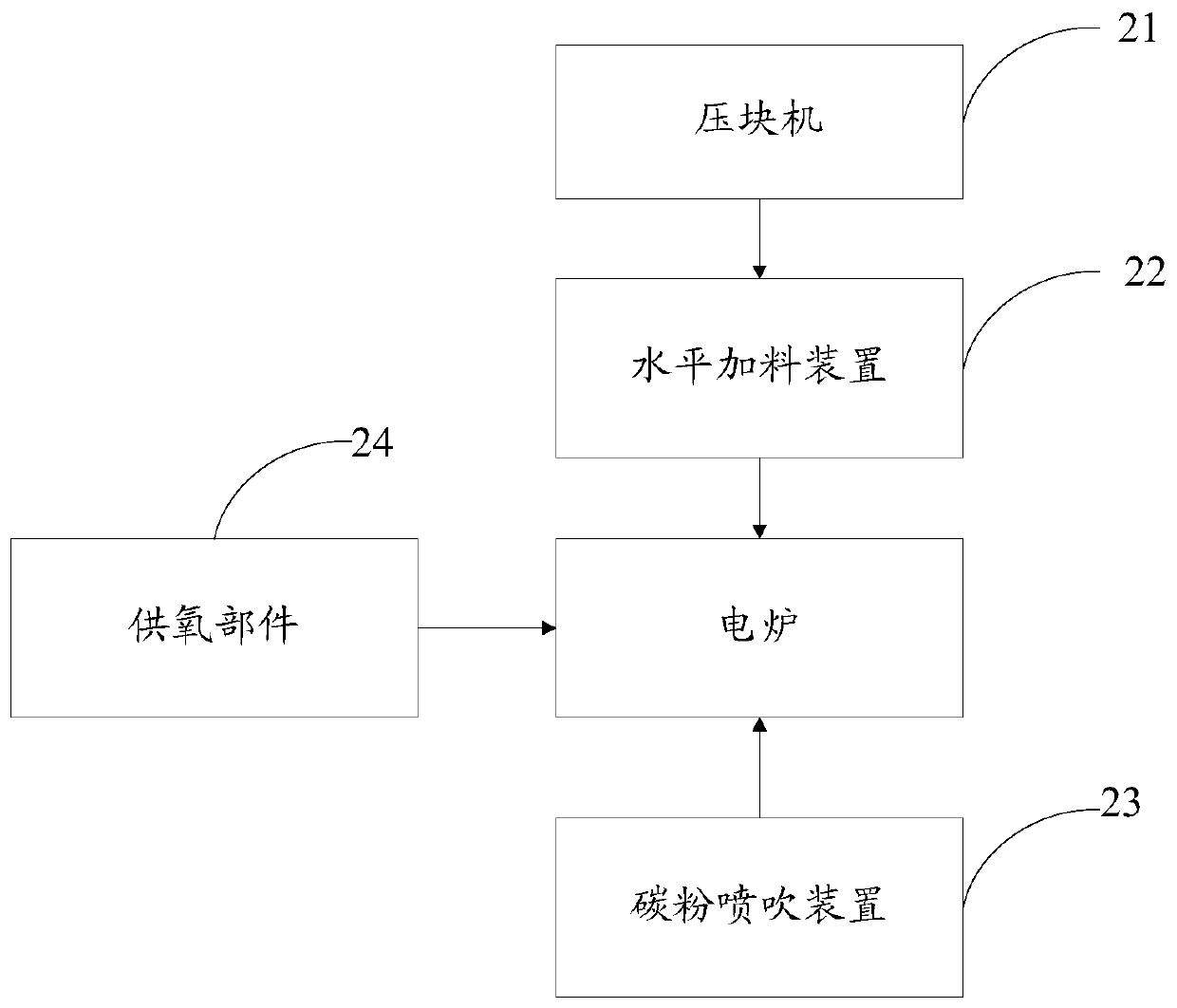

[0059] This embodiment provides an electric furnace steelmaking system, such as figure 2 As shown, the system includes: a briquetting machine 21, a horizontal feeding device 22, a carbon powder injection device 23 and an oxygen supply part 24; wherein,

[0060] In order to increase the feeding speed of the electric furnace, the briquetting machine 21 is used to make carbon briquettes by using scrap steel and coal particles; specifically includes:

[0061] placing the coal lump particles inside the steel scrap, so that the scrap steel wraps the coal lump particles;

[0062] Using a briquetting machine to press the steel scrap wrapped with the coal particles into the carbon-combined briquette.

[0063] Among them, the carbon content of the coal block formed by the coal particles in the carbon briquette is ≥75%, and the weight of each carbon briquette is 70-100kg; the coal content in each carbon briquette is 10-20kg , the length, width and height of each carbon briquetting blo...

Embodiment 3

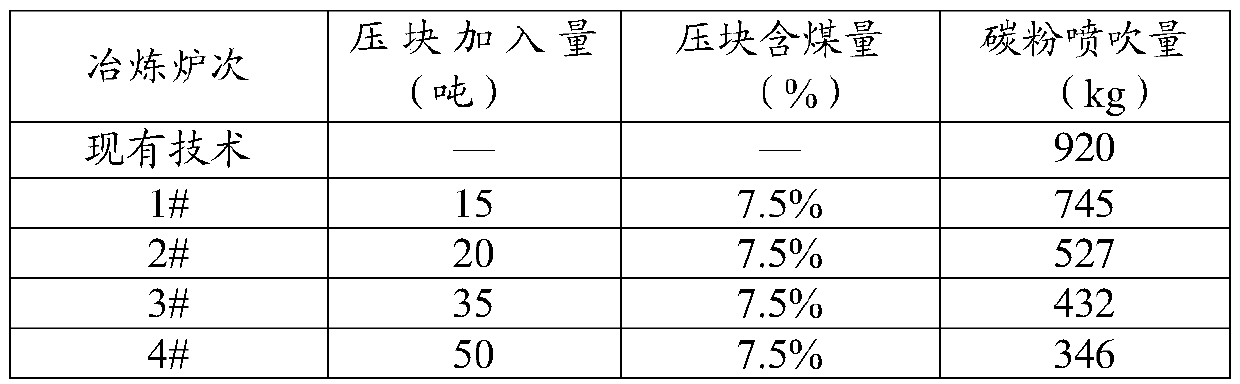

[0074] In actual application, when using the method provided in Embodiment 1 and the system provided in Embodiment 2 to carry out steelmaking in a 60-ton Consid electric furnace, the details are as follows:

[0075] First make carbon briquettes according to the method provided in Embodiment 1, the carbon content of the coal briquettes formed by the coal particles in the carbon briquettes is ≥75%, and the weight of each carbon briquette is 80kg; each carbon briquette The coal content in the block is 6kg (7.5% by weight), and the length, width and height of each carbon briquette are 200mm×300mm×300mm.

[0076] Scrap steel is a light and thin material, and the weight percentage of each component in the scrap steel includes: carbon C is 0.03%, copper Cu is 0.005%, nickel Ni is 0.05%, selenium As is 0.01%, and the rest is Fe and impurities.

[0077] After the carbon briquettes are made, during the four steelmaking processes, when the electric furnace is energized, use the horizonta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com