Waterborne UV (ultraviolet) antifouling self-cleaning coating and as well as preparation method and application thereof

A self-cleaning, water-based technology, applied in the field of coatings, can solve problems such as poor stain resistance, small contact angle, and slow film forming time, and achieve the effects of good adhesion, low surface tension, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

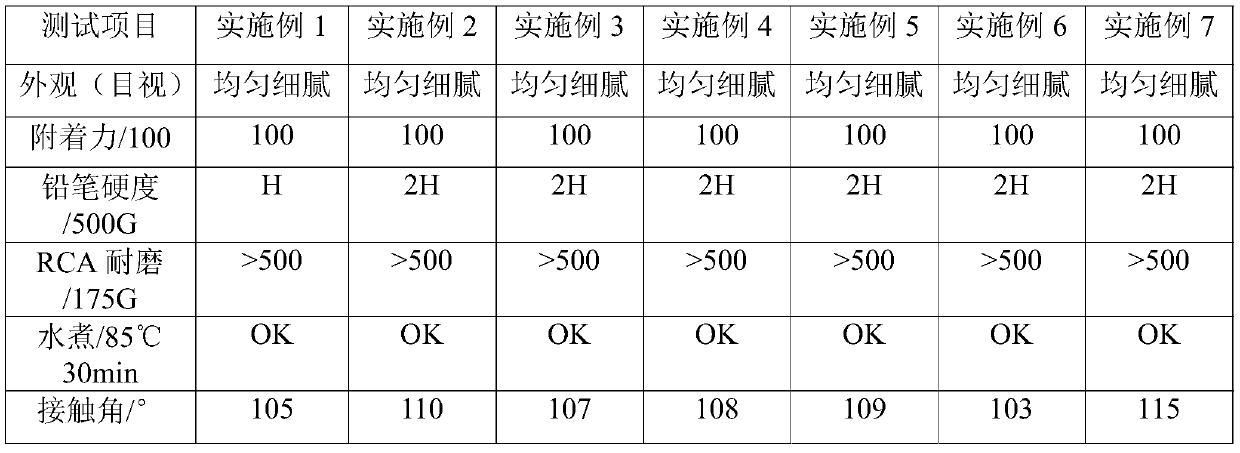

Examples

Embodiment 1

[0091] The present embodiment provides a kind of water-based UV anti-dirt self-cleaning coating and its preparation method, application, described water-based UV anti-dirt self-cleaning coating contains components (parts by weight) as shown in the following table 1:

[0092] The composition of coating components in the waterborne UV antifouling self-cleaning coating of table 1

[0093] Coating components parts by mass Waterborne Polyurethane Acrylic Emulsion 40 rheological agent 1 D 1 Defoamer 0.2 Dispersant 0.3 wax powder 7 matting powder 4 Waterborne UV Monomer 18 Photoinitiator 4 pH regulator 0.1 Deionized water 24.4

[0094] The preparation method of the water-based UV anti-fouling self-cleaning coating is as follows:

[0095] S11, according to the components and content contained in the water-based UV anti-fouling self-cleaning coating described in Table 1, take each component raw material re...

Embodiment 2

[0104] The present embodiment provides a kind of water-based UV anti-dirt self-cleaning coating and its preparation method, application, described water-based UV anti-dirt self-cleaning coating contains components (parts by weight) as shown in the following table 2:

[0105] The composition of coating components in the waterborne UV antifouling self-cleaning coating of table 2

[0106] Coating components parts by mass Waterborne Polyurethane Acrylic Emulsion 50 rheological agent 1 D 1 Defoamer 0.2 Dispersant 0.3 wax powder 7 matting powder 4 Waterborne UV Monomer 8 Photoinitiator 4 pH regulator 0.1 Deionized water 24.4

[0107] The preparation method of described water-based UV anti-dirt self-cleaning coating is as follows: the method that present embodiment prepares water-based UV anti-dirt self-cleaning coating is identical with embodiment 1.

[0108] The application of the water-based UV anti-f...

Embodiment 3

[0111] The present embodiment provides a kind of water-based UV anti-dirt self-cleaning coating and its preparation method, application, described water-based UV anti-dirt self-cleaning coating contains components (parts by weight) as shown in the following table 3:

[0112] Table 3 Composition of coating components in waterborne UV antifouling self-cleaning coating

[0113] Coating components parts by mass Waterborne Polyurethane Acrylic Emulsion 60 rheological agent 1 D 1 Defoamer 0.2 Dispersant 0.3 wax powder 7 matting powder 4 Waterborne UV Monomer 0 Photoinitiator 4 pH regulator 0.1 Deionized water 22.4

[0114] The preparation method of described water-based UV anti-dirt self-cleaning coating is as follows: the method that present embodiment prepares water-based UV anti-dirt self-cleaning coating is identical with embodiment 1.

[0115] The application of the water-based UV anti-fouling self...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com