Macadam real paint and preparation method thereof

A technology of gravel and real lacquer, which is applied to paints, coatings, and anti-corrosion coatings containing biocide, which can solve the problems of poor low-temperature stability and achieve the effects of lower film-forming temperature, strong three-dimensional effect, and strong decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

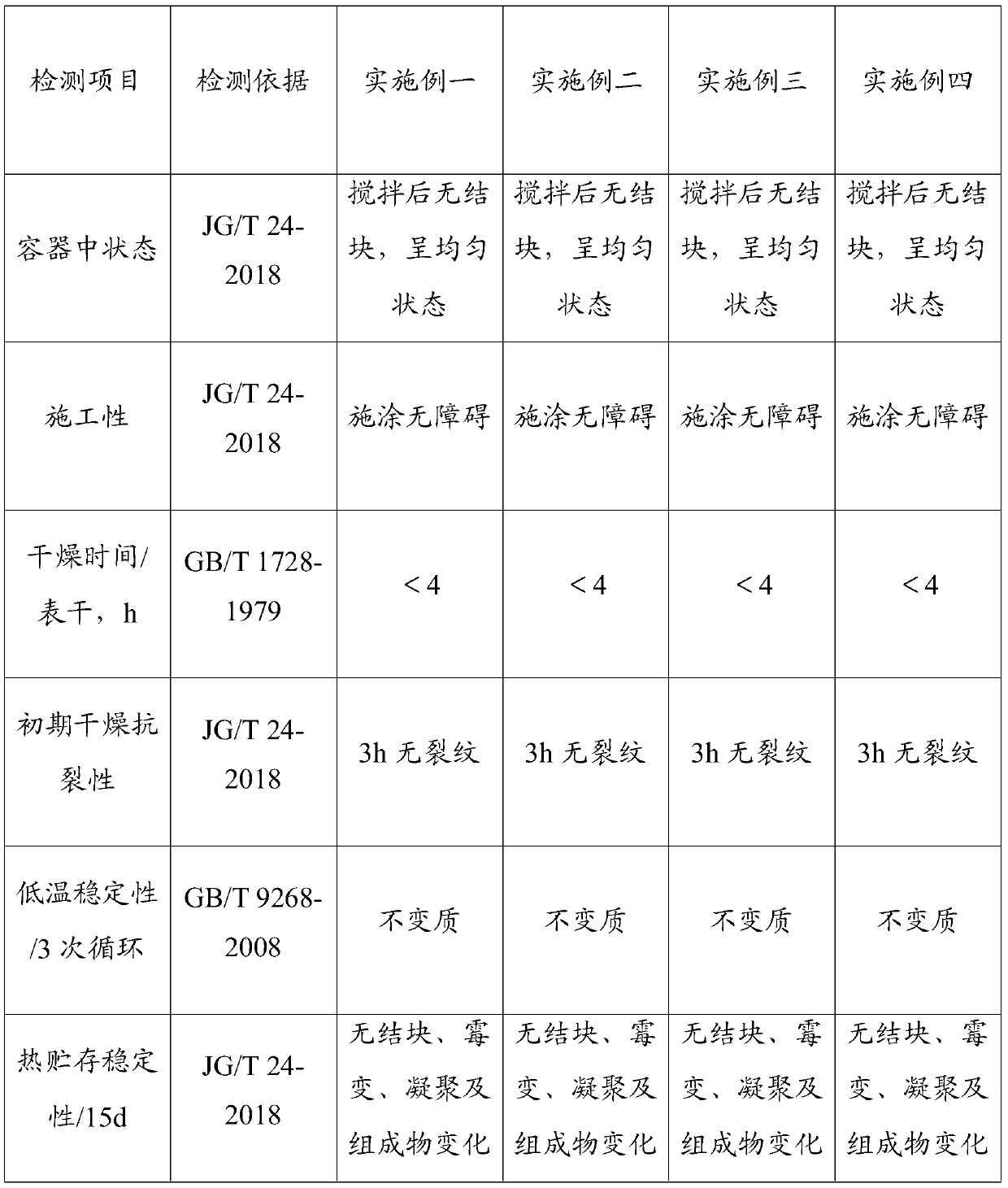

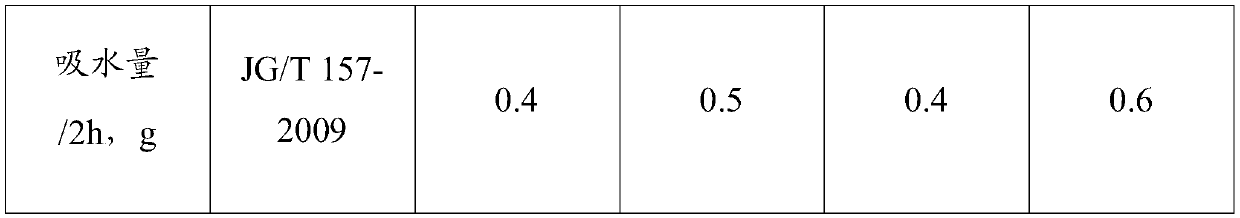

Examples

Embodiment 1

[0016] A kind of crushed stone lacquer provided by the embodiment of the present invention is composed of the following components in mass percentage: 20% of silicon acrylic emulsion, 76.2% of natural colored stone powder, 0.2% of hydroxyethyl cellulose, 2% of propylene glycol, alcohol Ester twelve 1%, thickener 0.5%, preservative 0.1%.

[0017] Among them, the solid content of silicone acrylic emulsion is 54.5%, the fineness of natural colored stone powder is 325 mesh, the viscosity of hydroxyethyl cellulose is 100,000, the thickener is polyurethane thickener, and the preservative is methyl p-hydroxybenzoate ester.

Embodiment 2

[0019] A crushed stone real lacquer provided in the embodiment of the present invention is composed of the following components in mass percentage: 15% of silicon-acrylic emulsion, 80% of natural colored stone powder, 0.1% of hydroxyethyl cellulose, 4.6% of propylene glycol, alcohol Ester twelve 0.1%, thickener 0.1%, preservative 0.1%.

[0020] Among them, the solid content of silicone acrylic emulsion is 50%, the fineness of natural colored stone powder is 400 mesh, the viscosity of hydroxyethyl cellulose is 150,000, the thickener is polyurethane thickener, and the preservative is methyl p-hydroxybenzoate ester.

Embodiment 3

[0022] A crushed stone real lacquer provided in the embodiment of the present invention is composed of the following components in mass percentage: 25% of silicon-acrylic emulsion, 70% of natural colored stone powder, 0.5% of hydroxyethyl cellulose, 1.9% of propylene glycol, alcohol Ester twelve 2%, thickener 0.5%, preservative 0.1%.

[0023] Among them, the solid content of silicone acrylic emulsion is 52%, the fineness of natural colored stone powder is 325 mesh, the viscosity of hydroxyethyl cellulose is 100,000, the thickener is polyacrylate thickener, and the preservative is p-hydroxybenzene Methyl formate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com