Cyanobacteria-based biological composite film material with functions of water resistance and light blocking, and preparation method thereof

A composite film, cyanobacteria-based technology, applied in the field of materials science, can solve the problems of wasting cyanobacterial nutrients, low lactic acid conversion rate, difficult disposal of waste residues, etc., and achieves high utilization rate of cyanobacteria, water resistance and light blocking properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

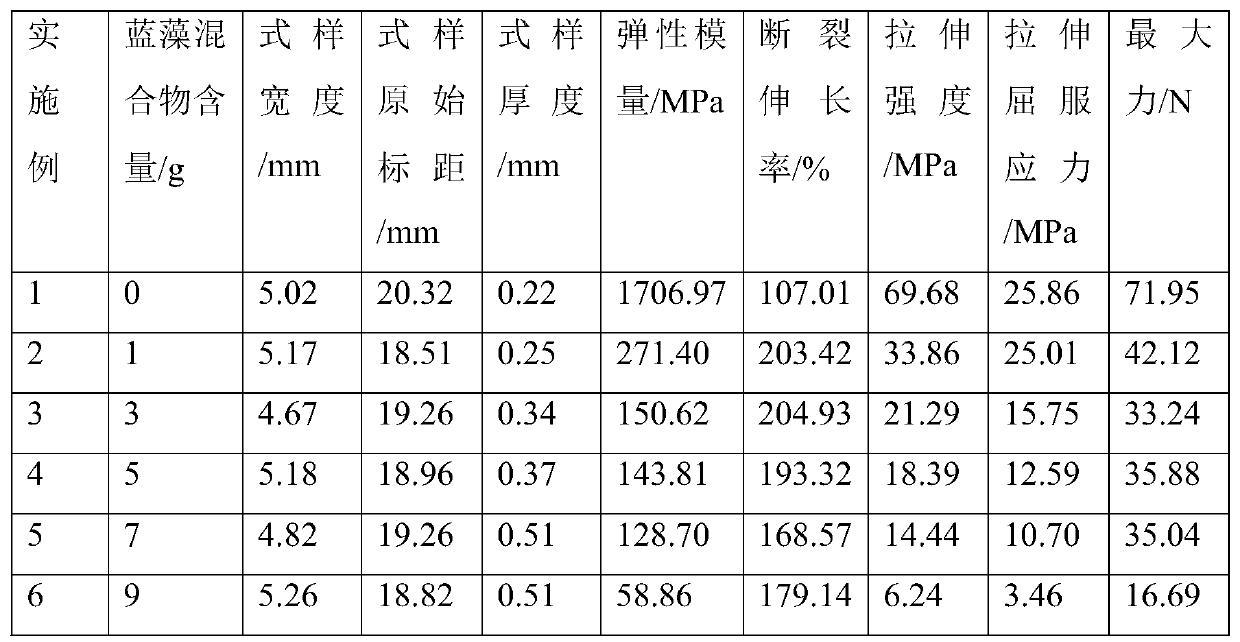

Embodiment 1

[0048] 1. Prepare the mixture

[0049] Mix 1 g of polyethylene glycol, 0.75 g of guanidine hydrochloride and 0.5 g of carboxymethyl cellulose with 47.75 g of water to make a homogenate, stir evenly, and react at room temperature for 2 hours to obtain a mixed solution.

[0050] 2. Preparation of polyvinyl alcohol / nanocellulose mixture

[0051] (1) Weigh 8 g of polyvinyl alcohol and mix it with 72 g of water, swell at room temperature and then heat (55° C.) for 2 hours to dissolve to obtain a polyvinyl alcohol solution with a concentration of 10%.

[0052] (2) Weighing 40 g of nanocellulose solution with a concentration of 1%, mixed with the polyvinyl alcohol solution and stirred for 1 hour to obtain a polyvinyl alcohol / nanocellulose mixed solution.

[0053] 3. Preparation of polyvinyl alcohol / nanocellulose composite film

[0054] Mix 20 g of the above-mentioned polyvinyl alcohol / nanocellulose solution with 1 g of the mixed solution, add 0.5 g of coupling agent 3-glycidyloxypr...

Embodiment 2

[0056] 1. Preparation of cyanobacteria mixture

[0057] Weigh 1 g of blue-green algae powder and mix it with 46.75 g of water to make a homogenate, add 1 g of polyethylene glycol, 0.75 g of guanidine hydrochloride and 0.5 g of carboxymethyl cellulose to the homogenate, stir evenly, and react at room temperature for 2 Hours, the blue-green algae mixture was obtained.

[0058] 2. Preparation of polyvinyl alcohol / nanocellulose mixture

[0059] (1) Weigh 8 g of polyvinyl alcohol and mix it with 72 g of water, swell at room temperature and then heat (55° C.) for 2 hours to dissolve to obtain a polyvinyl alcohol solution with a concentration of 10%.

[0060] (2) Weighing 40 g of nanocellulose solution with a concentration of 1%, mixed with the polyvinyl alcohol solution and stirred for 1 hour to obtain a polyvinyl alcohol / nanocellulose mixed solution.

[0061] 3. Preparation of cyanobacteria / polyvinyl alcohol / nanocellulose composite film

[0062] Mix 20 g of the above polyvinyl a...

Embodiment 3

[0065] 1. Preparation of cyanobacteria mixture

[0066] Weigh 1 g of blue-green algae powder and mix it with 46.75 g of water to make a homogenate, add 1 g of polyethylene glycol, 0.75 g of guanidine hydrochloride and 0.5 g of carboxymethyl cellulose to the homogenate, stir evenly, and react at room temperature for 2 Hours, the blue-green algae mixture was obtained.

[0067] 2. Preparation of polyvinyl alcohol / nanocellulose mixture

[0068] (1) Weigh 8 g of polyvinyl alcohol and mix it with 72 g of water, swell at room temperature and then heat (55° C.) for 2 hours to dissolve to obtain a polyvinyl alcohol solution with a concentration of 10%.

[0069] (2) Weighing 40 g of nanocellulose solution with a concentration of 1%, mixed with the polyvinyl alcohol solution and stirred for 1 hour to obtain a polyvinyl alcohol / nanocellulose mixed solution.

[0070] 3. Preparation of cyanobacteria / polyvinyl alcohol / nanocellulose composite film

[0071] Mix 20 g of the above polyvinyl a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com