Preparation method of 6-chloro-2,4-dinitroaniline

A technology of dinitroaniline and sodium chlorate, applied in the chemical industry, can solve the problems of low cleaning efficiency, high water consumption, increased production cost, etc., and achieve the effects of reducing waste water discharge, improving cleaning efficiency, and energy saving and emission reduction benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

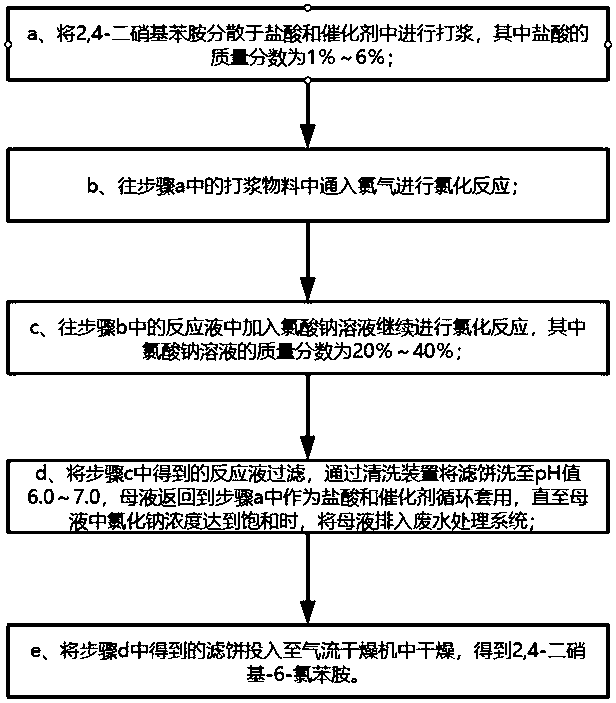

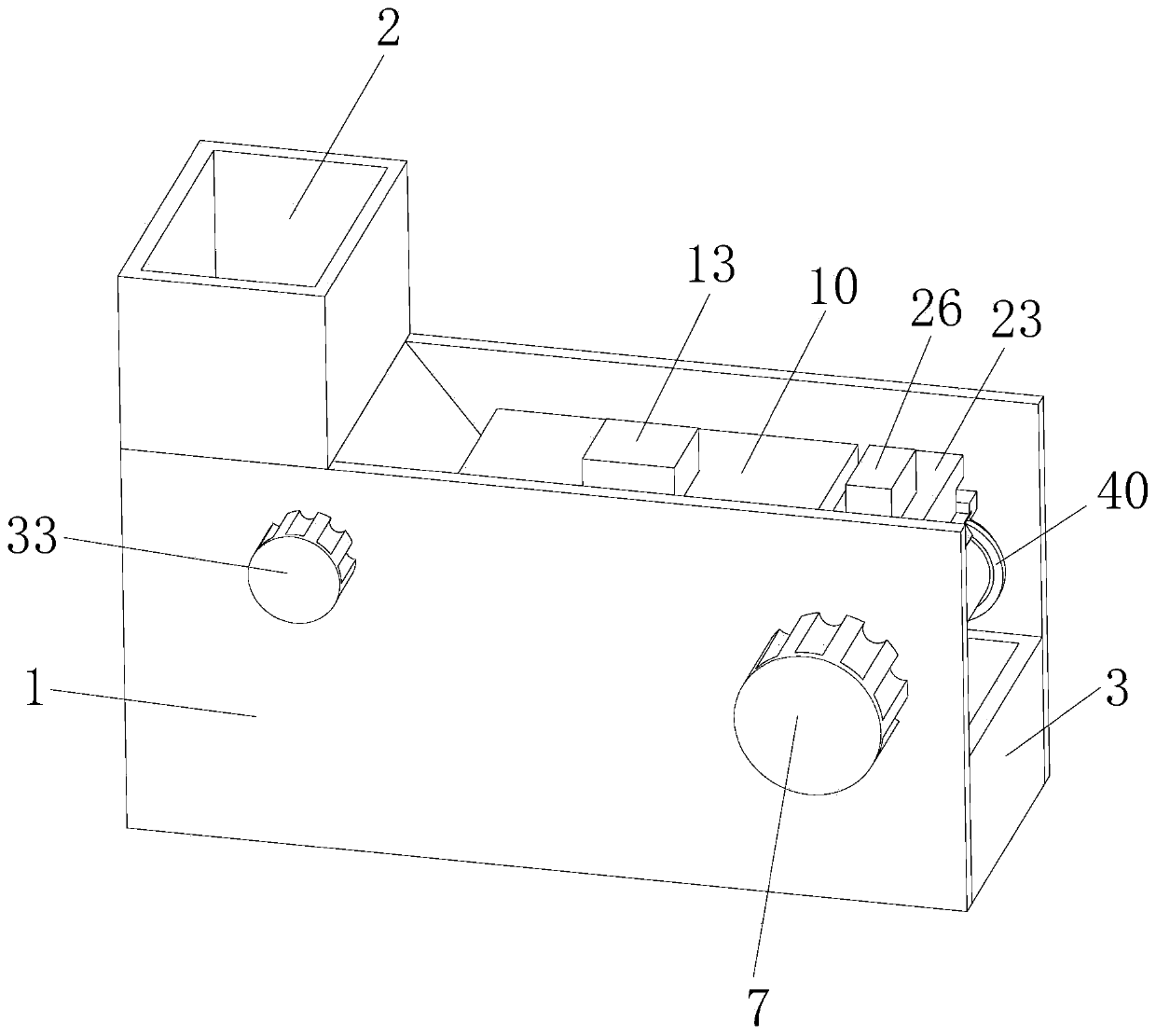

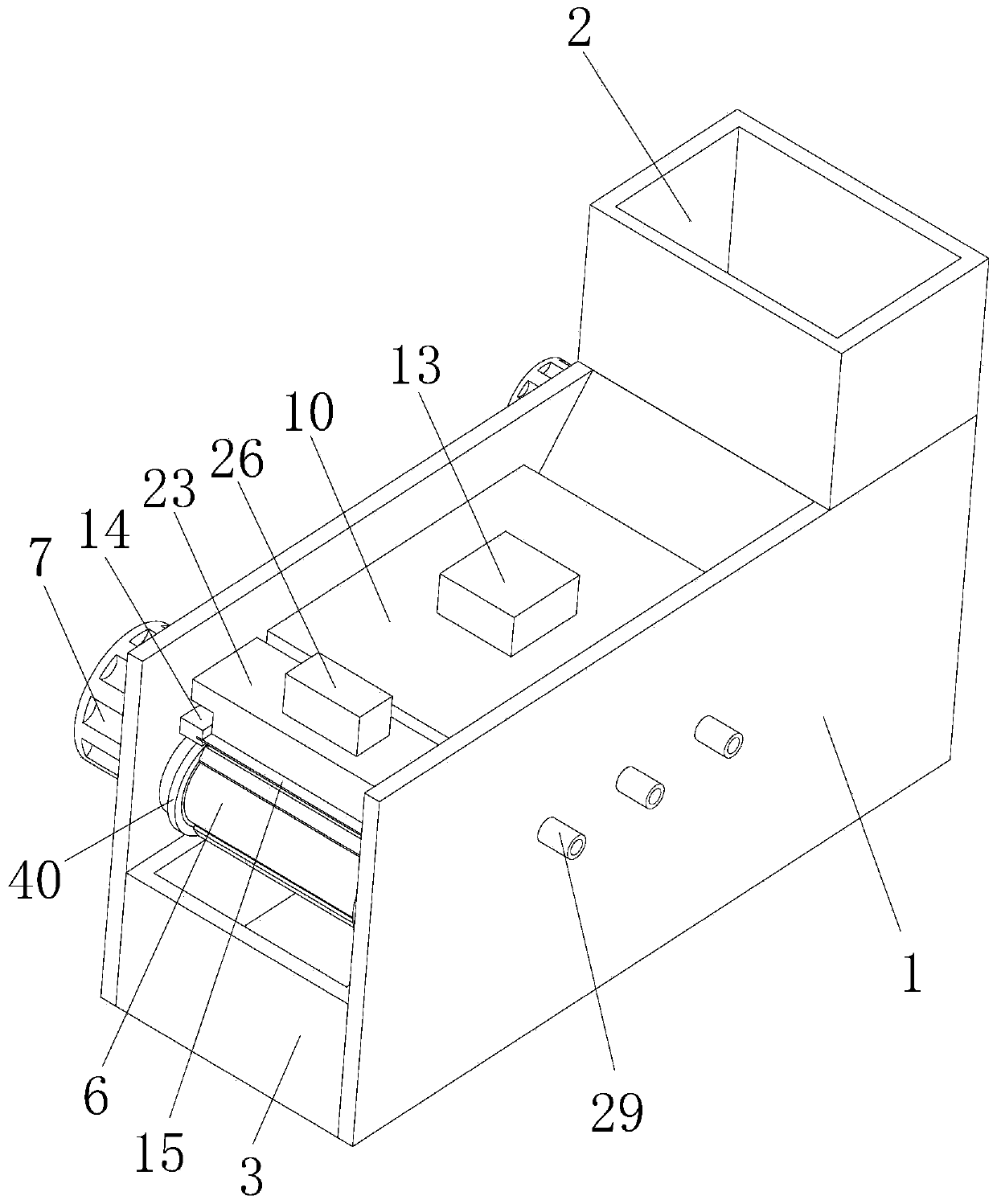

[0037] Such as Figure 1-7Shown, a kind of 6-chloro-2,4-dinitroaniline preparation method comprises the following steps:

[0038] a. Dispersing 2,4-dinitroaniline in hydrochloric acid and catalyst for beating, wherein the mass fraction of hydrochloric acid is 1%;

[0039] B, feed chlorine into the beating material in step a and carry out chlorination reaction;

[0040] C, add sodium chlorate solution in the reaction solution in step b and continue chlorination reaction, wherein the massfraction of sodium chlorate solution is 20%;

[0041] d, filter the reaction solution obtained in step c, wash the filter cake to a pH value of 6.0 to 7.0 through a cleaning device, and return the mother liquor to step a for recycling as hydrochloric acid and catalyst until the concentration of sodium chloride in the mother liquor reaches saturation. Discharge the mother liquor into the wastewater treatment system;

[0042] e, putting the filter cake obtained in step d into an airflow dryer f...

Embodiment 2

[0066] Such as figure 1 Shown, a kind of 6-chloro-2,4-dinitroaniline preparation method comprises the following steps:

[0067] a. Dispersing 2,4-dinitroaniline in hydrochloric acid and catalyst for beating, wherein the mass fraction of hydrochloric acid is 6%;

[0068] B, feed chlorine into the beating material in step a and carry out chlorination reaction;

[0069] C, add sodium chlorate solution in the reaction solution in step b and continue chlorination reaction, wherein the massfraction of sodium chlorate solution is 40%;

[0070] d, filter the reaction solution obtained in step c, wash the filter cake to a pH value of 6.0 to 7.0 through a cleaning device, and return the mother liquor to step a for recycling as hydrochloric acid and catalyst until the concentration of sodium chloride in the mother liquor reaches saturation. Discharge the mother liquor into the wastewater treatment system;

[0071] e. Put the filter cake obtained in step d into an airflow dryer to dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com