Method for controlling disinfection by-products of drinking water from surface water

A technology for disinfection by-products and surface water, applied in the direction of water pollutants, water/sewage treatment, chemical instruments and methods, etc., can solve the problem of not being able to intercept microorganisms and other fine particles, not being able to remove dissolved organic matter in water, and removing dissolved organic matter Low efficiency and other problems, to achieve the effect of improving the pre-oxidation effect and coagulation efficiency, low cost, and preventing aluminum from exceeding the standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

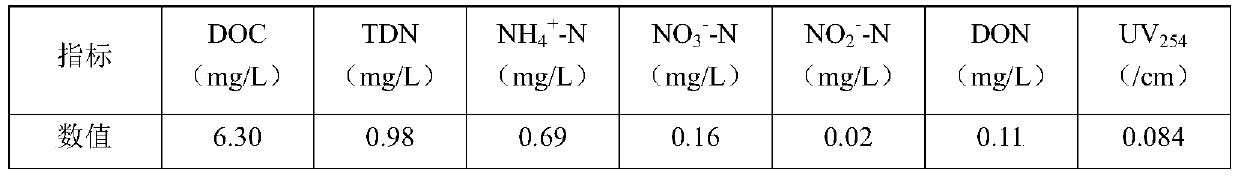

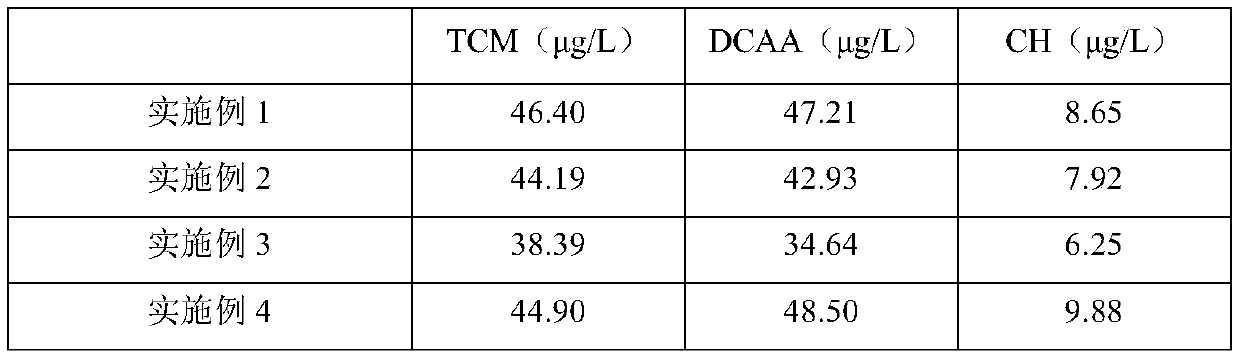

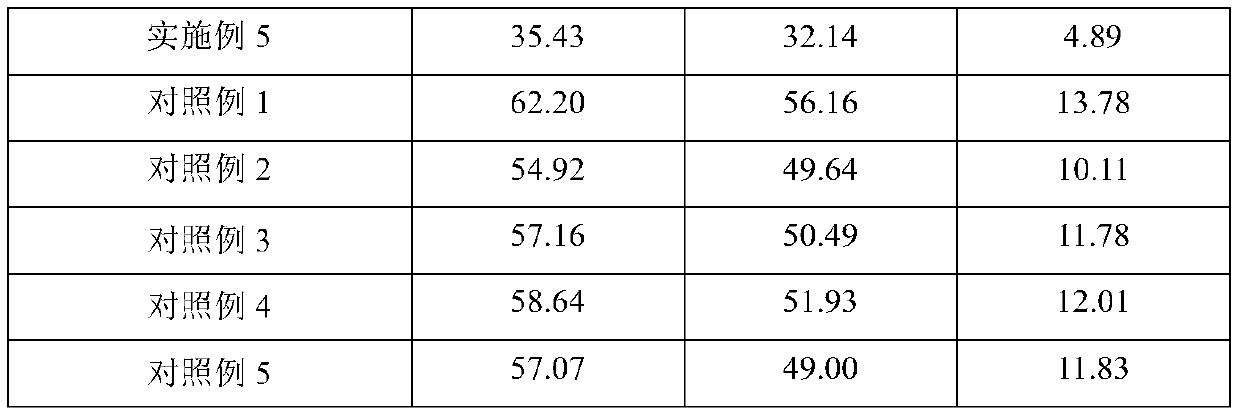

[0031]Take 1000mL surface water (see Table 1 for the basic physical and chemical properties), first add 0.05mg / L potassium permanganate to the water, stir at a speed of 300r / min for 5min, and then add 0.05mg / L potassium permanganate to the water , stirred at a speed of 150r / min for 10min; added 10mg / L of PACl to the pre-oxidized water, stirred at a speed of 200r / min for 5min, then added PACl 10mg / L, and stirred at a speed of 100r / min for 10min; Set aside to settle for 30 minutes; take the supernatant for ceramic membrane filtration (ceramic membrane pore size 0.1 μm); perform chlorine disinfection on ceramic membrane effluent (chlorine addition 30mg / L, temperature 25±0.5°C, pH 7.0±0.1, avoid light reaction 24h); after disinfection for 24h, add excessive ascorbic acid to terminate the chlorine disinfection reaction, and measure the concentration of disinfection by-products in the water, the results are shown in Table 2.

[0032] Table 1 Basic physical and chemical properties of...

Embodiment 2

[0035] With reference to Example 1, the amount of potassium permanganate added twice is replaced by 0.2mg / L, and other conditions are constant, specifically:

[0036] Take 1000mL surface water, first add 0.1mg / L potassium permanganate to the water, stir at a speed of 300r / min for 5min, then add 0.1mg / L potassium permanganate to the water, stir at a speed of 150r / min 10min; add 10mg / L PACl to the pre-oxidized water, stir at a speed of 200r / min for 5min, then add 10mg / L of PACl, stir at a speed of 100r / min for 10min; let it settle for 30min; take the supernatant Filter the liquid through ceramic membrane (pore size of ceramic membrane is 0.1μm); perform chlorine disinfection on ceramic membrane effluent (chlorination amount 30mg / L, temperature 25±0.5°C, pH 7.0±0.1, light-shielding reaction for 24h); after disinfection for 24h, add Excessive ascorbic acid terminated the chlorine disinfection reaction, and the concentration of disinfection by-products in water was measured. The re...

Embodiment 3

[0038] With reference to Example 1, the amount of potassium permanganate added twice is replaced by 0.5mg / L, and other conditions are constant, specifically:

[0039] Take 1000mL surface water, first add 0.25mg / L potassium permanganate to the water, stir at a speed of 300r / min for 5min, then add 0.25mg / L potassium permanganate to the water, stir at a speed of 150r / min 10min; add 10mg / L PACl to the pre-oxidized water, stir at a speed of 200r / min for 5min, then add 10mg / L of PACl, stir at a speed of 100r / min for 10min; let it settle for 30min; take the supernatant Filter the liquid through ceramic membrane (pore size of ceramic membrane is 0.1μm); perform chlorine disinfection on ceramic membrane effluent (chlorination amount 30mg / L, temperature 25±0.5°C, pH 7.0±0.1, light-shielding reaction for 24h); after disinfection for 24h, add Excessive ascorbic acid terminated the chlorine disinfection reaction, and the concentration of disinfection by-products in water was measured. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com