Water washing method for producing hydrogen peroxide by anthraquinone method

A technology of hydrogen peroxide and anthraquinone method, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, inorganic chemistry, etc., can solve problems such as affecting hydrogenation reaction, etc. To achieve the effect of reducing side reactions, reducing production costs, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

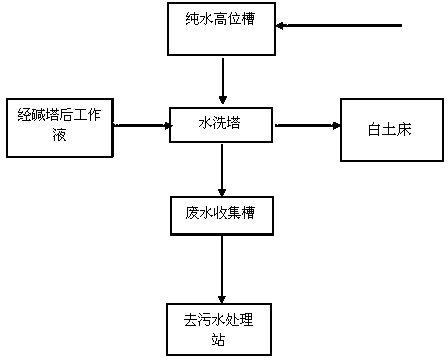

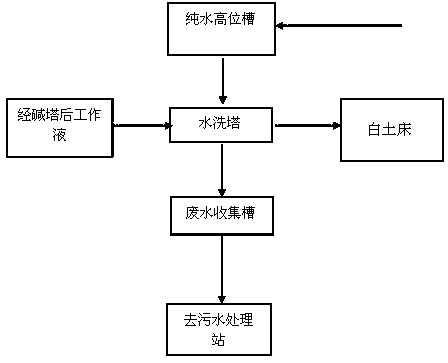

[0016] Such as figure 1 As shown, a water washing method for producing hydrogen peroxide by anthraquinone method, the outlet regulating valve of the alkali tower controls the amount of working liquid entering the water washing tower through the outlet of the alkali tower, and slowly enters from the bottom of the water washing tower, and flows from the pure water head tank to the water washing tower Inject deionized water, the pure water regulating valve controls the amount of pure water injection in the washing tower, the interface between the water and the working fluid in the washing tower is controlled between 30% and 60%, the deionized water is mixed with the working fluid, and the working fluid is washed From the bottom to the top of the tower, it enters the clay bed after overflowing from the top of the water washing tower, and the water phase is discharged to the waste water collection tank through the bottom.

[0017] As the running time increases, the aqueous solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com