Anthraquinone method hydrogen peroxide extraction tower

A technology of hydrogen peroxide and extraction tower, which is applied in the field of hydrogen peroxide production and extraction by anthraquinone method, can solve the problems of easy agglomeration, uneven distribution of oxidizing liquid, poor diffusion effect of hydrogen peroxide, etc., and achieves the effects of uniform distribution and low hydrogen peroxide content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

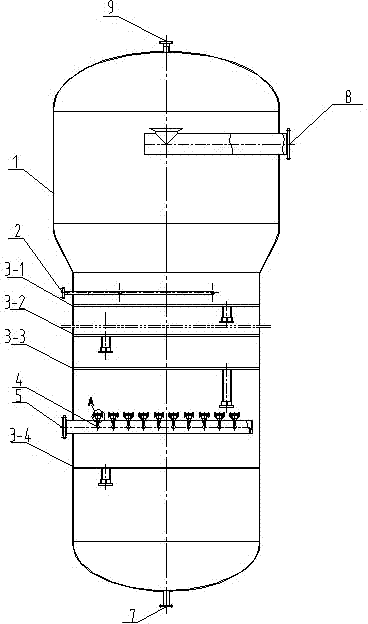

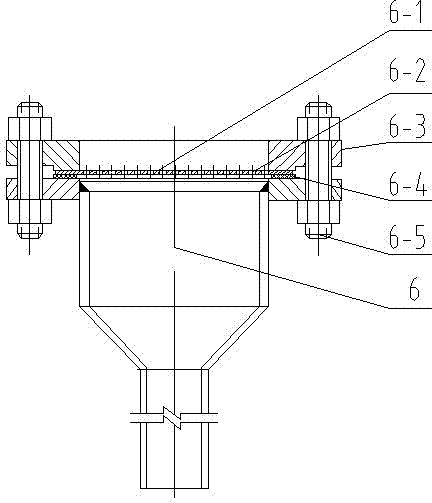

[0014] Such as figure 1 , 2 As shown, the present invention includes a shell 1, and the first sieve plate 3-1, the second sieve plate 3-2, the third sieve plate 3-3 and the fourth sieve plate 3- 4. Pure water inlet pipe 2, oxidizing solution inlet main pipe 5, hydrogen peroxide product outlet pipe 7, raffinate outlet pipe 8 and vent pipe 9 are welded on the shell 1 and communicated with the inner cavity of the shell 1, and the pure water inlet pipe 2 is set Above the first sieve plate 3-1, the hydrogen peroxide product outlet pipe 7 is arranged at the bottom of the housing 1, the raffinate outlet pipe 8 is arranged at the upper part of the housing 1 and above the pure water inlet pipe 2, and the vent pipe 9 is arranged on the top of the housing 1. The main pipe 5 for the inlet of the oxidizing solution is arranged between the third sieve plate 3-3 and the fourth sieve plate 3-4. The main pipe 5 for the inlet of the oxidizing solution is connected to several branch pipes 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com