Copper-aluminum film etching solution

An etchant, copper and aluminum technology, applied in the field of etchant, can solve the problems of boiling and explosive etching efficiency, reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a copper aluminum film etching solution, relative to the total weight of the etching solution, by weight, comprising: 6.3% hydrogen peroxide, 0.5% phenylurea (hydrogen peroxide stabilizer), 0.15% 5-amino-1H-tetrazolium monohydrate (etch inhibitor), 8% citric acid (organic acid), 7% 2-amino-2-methyl-1-propanol (alcoholamine ), 0.5% polyethylene glycol (surfactant), 1.8% ammonium dihydrogen phosphate (inorganic hydrogen phosphate), 1.2% phosphoric acid (inorganic acid) and deionized water of the remainder.

[0045] The preparation method of the copper-aluminum film etching solution described in this embodiment is: dissolving each component of the etching solution in deionized water, stirring and dissolving for 1.5 to 3 minutes at 15 to 30 degrees Celsius and 150 to 800 rpm hours until a clear and homogeneous mixed solution appears.

Embodiment 2

[0047] This embodiment provides a copper aluminum film etching solution, relative to the total weight of the etching solution, by weight, comprising: 6.3% hydrogen peroxide, 0.5% phenylurea (hydrogen peroxide stabilizer), 0.15% 5-amino-1H-tetrazolium monohydrate (etch inhibitor), 8% citric acid (organic acid), 7% 2-amino-2-methyl-1-propanol (alcoholamine ), 0.5% polyethylene glycol (surfactant), 1.8% ammonium dihydrogen phosphate (inorganic hydrogen phosphate), 1.2% phosphoric acid (inorganic acid), 0.05% ammonium fluoride (fluoride) and other amount of deionized water.

[0048] The preparation method of the copper-aluminum film etching solution described in this embodiment is: dissolving each component of the etching solution in deionized water, stirring and dissolving for 1.5 to 3 minutes at 15 to 30 degrees Celsius and 150 to 800 rpm hours until a clear and homogeneous mixed solution appears.

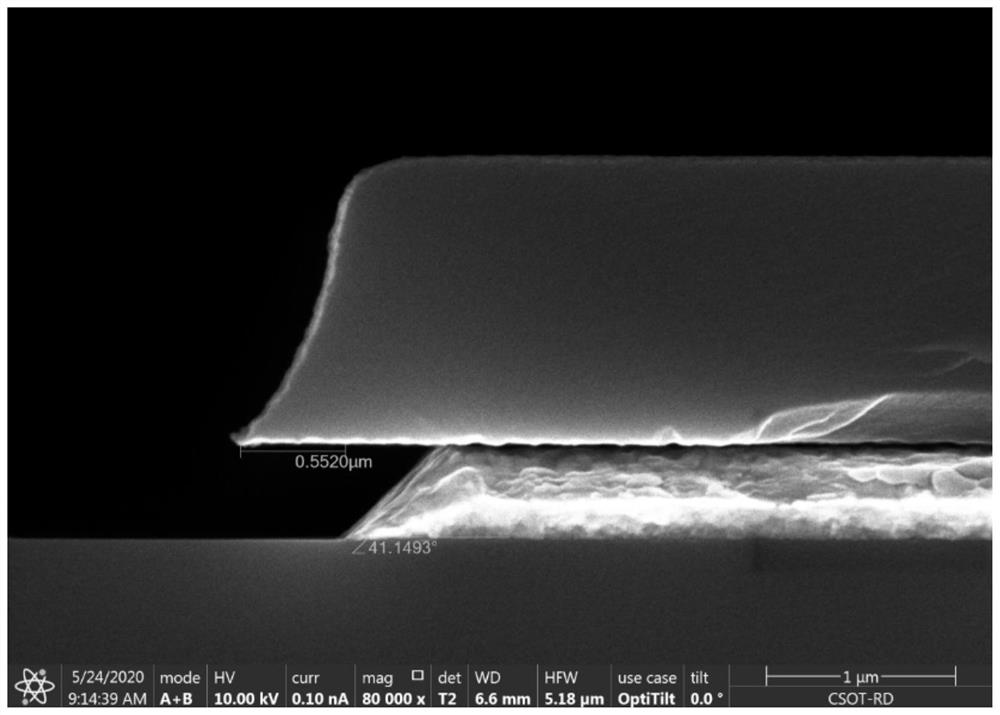

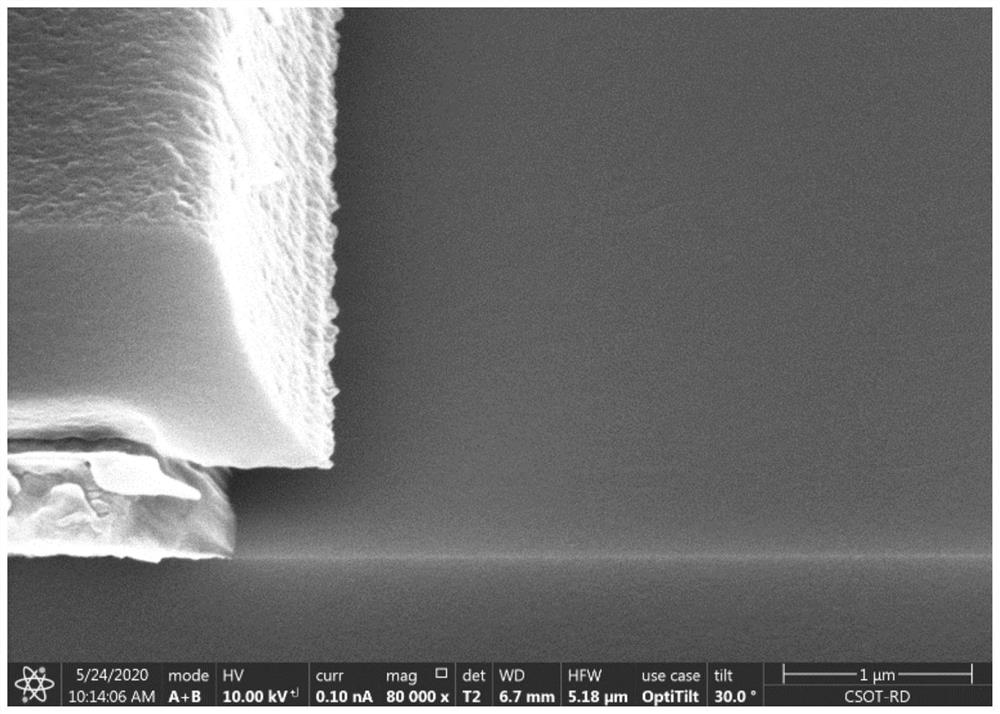

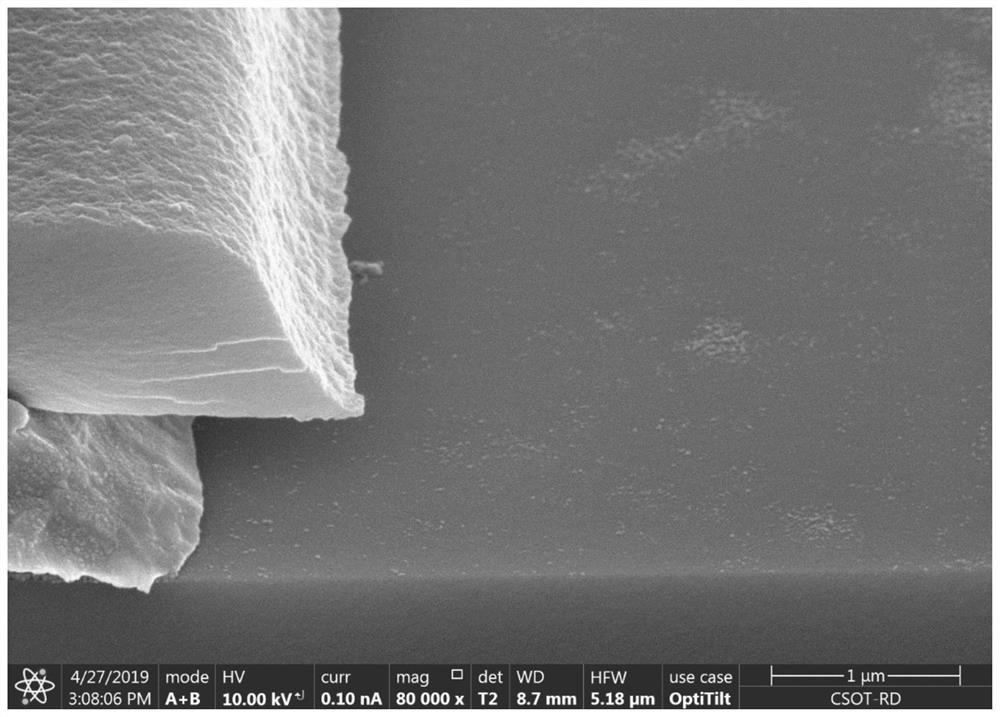

[0049] The effect of the etching solution described in the embodiment of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com