Hydraulic-type clutch and brake control system

A brake control, hydraulic technology, applied in the field of forklifts, to achieve the effect of solving early wear, avoiding consumption and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, the present invention will be further described through embodiment.

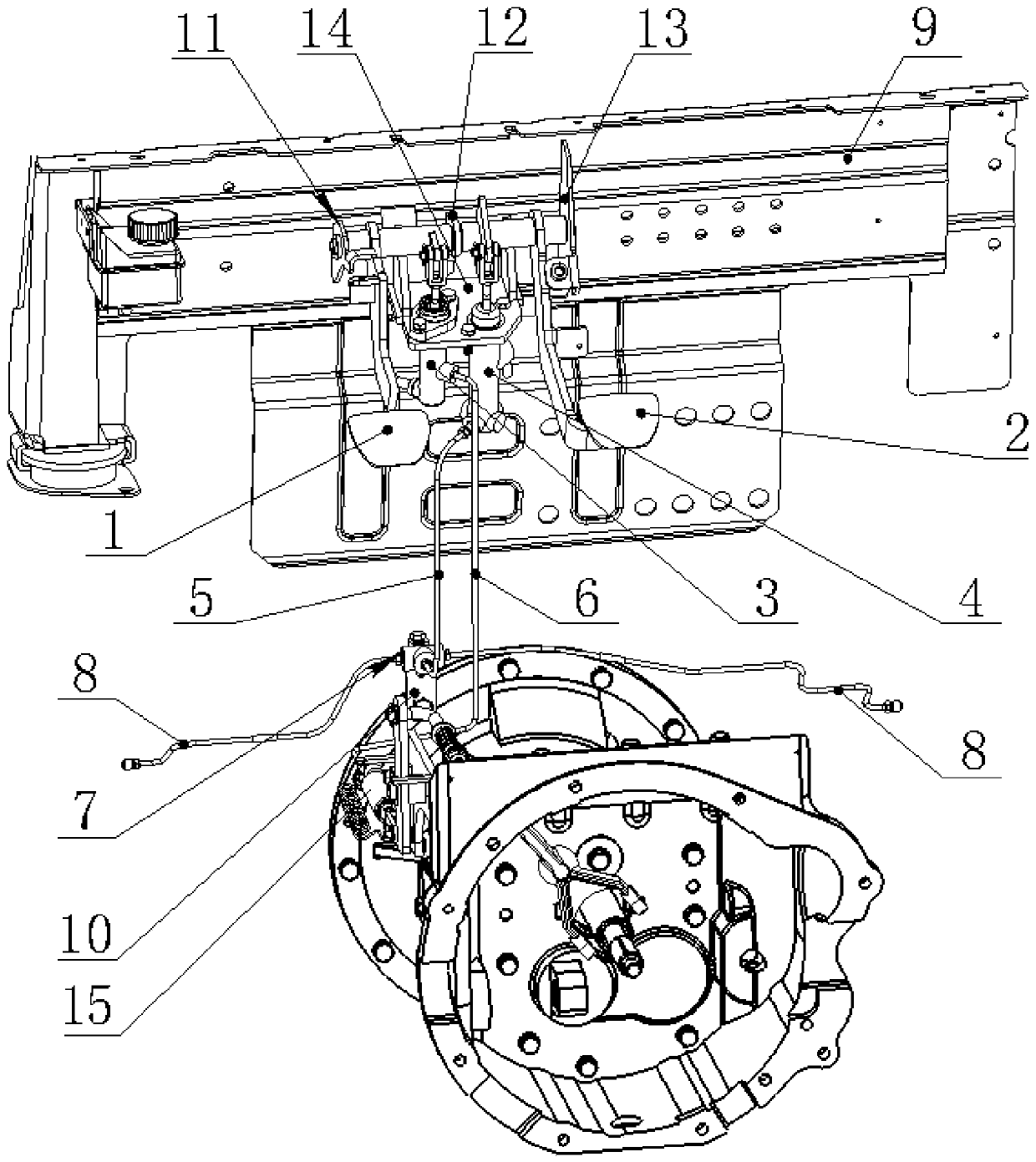

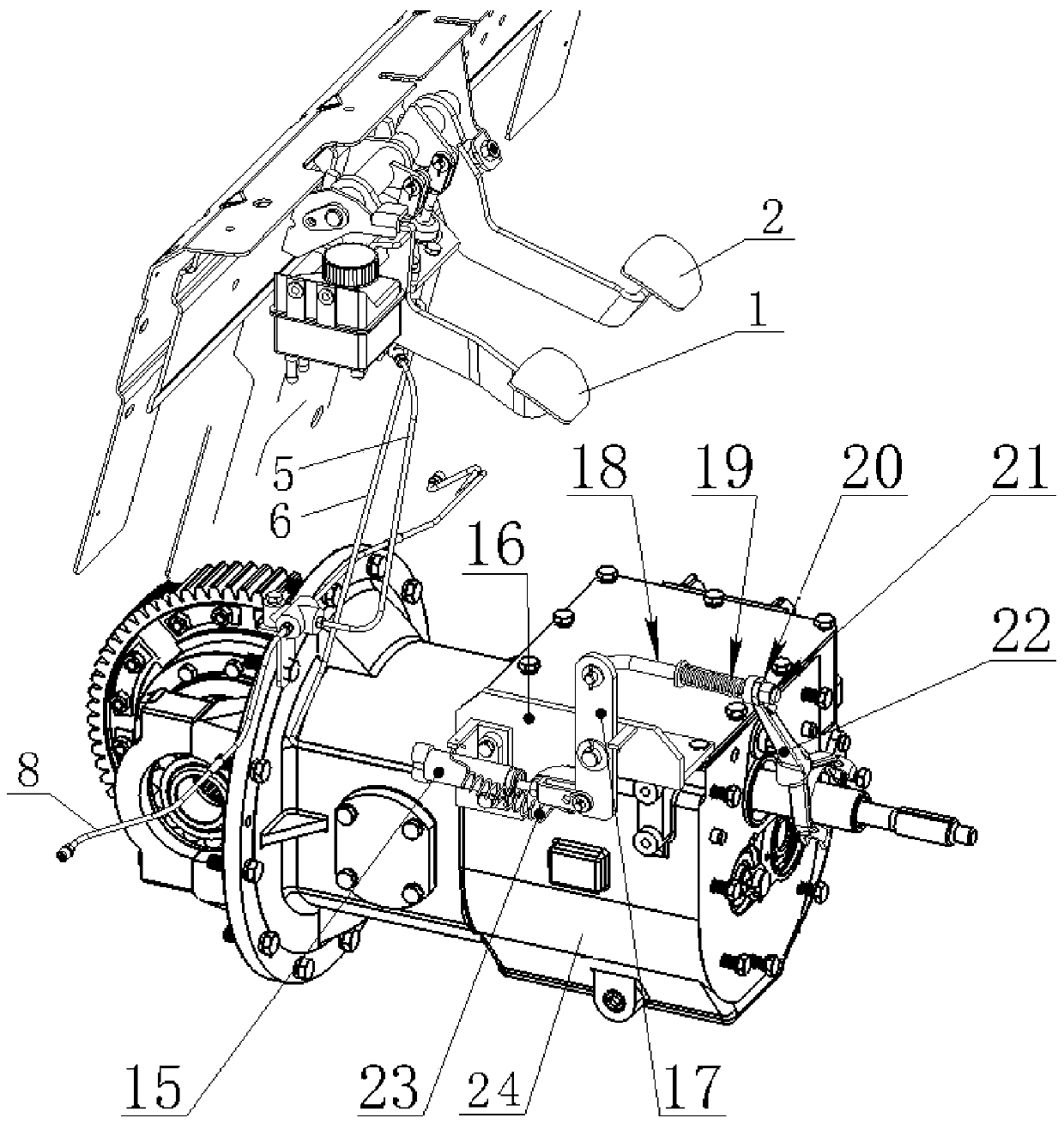

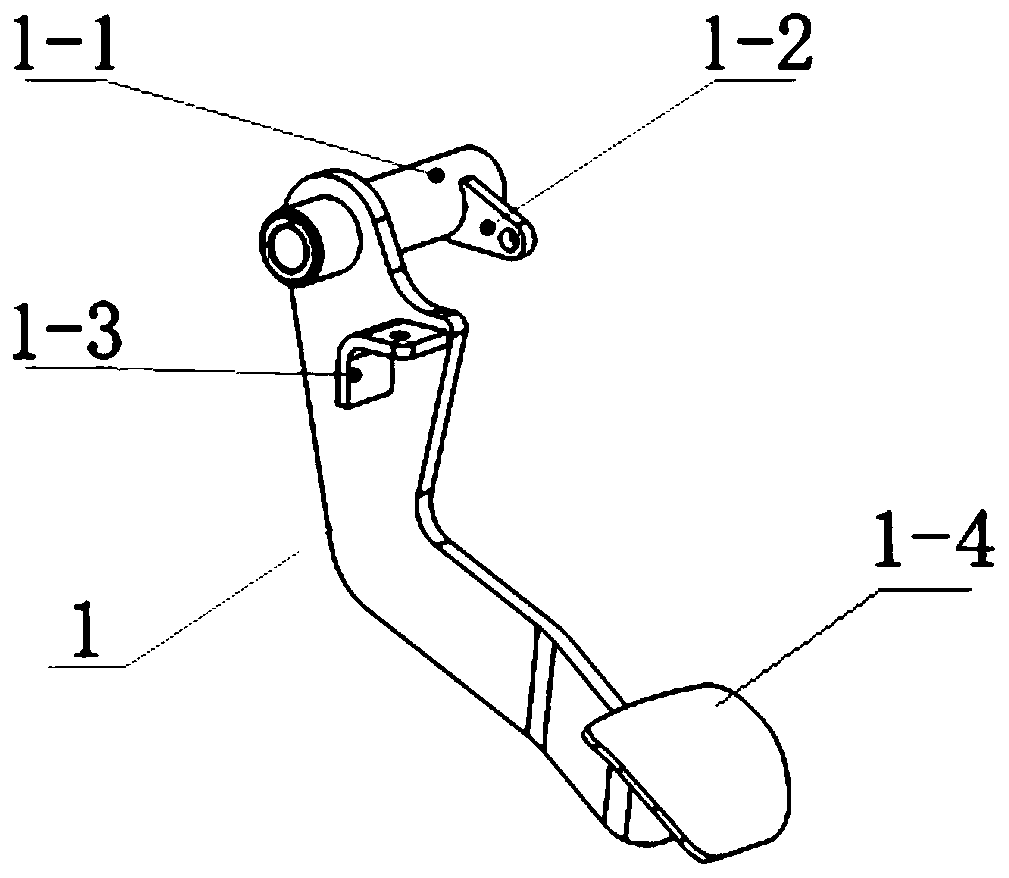

[0039] Such as Figure 1-9As shown, a hydraulic clutch and brake control system includes a shift fork 22 installed on the gearbox 24, and a clutch pedal assembly 1 and a brake pedal assembly coaxially rotated on the front plate assembly 9 2. The clutch pedal assembly 1 and the brake pedal assembly 2 are respectively connected to the clutch master cylinder 3 and the brake master cylinder 4, and the oil outlet of the clutch master cylinder 3 is connected to the clutch cylinder 15 through the clutch hose 6 The oil inlet is connected, and the oil outlet of the brake master cylinder 4 is connected with the oil inlet of the brake cylinder through the brake rubber hose 5; the piston end of the clutch cylinder 15 is fixedly connected with one end of the rocker arm assembly 17 , the other end of the rocker arm assembly 17 is fixedly connected to one end of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com