Iron sesquioxide nanoring photocatalyst and preparation method thereof

A technology of ferric oxide and photocatalyst, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of easy recombination of photogenerated electron holes, etc. Achieve the effect of increasing reaction sites, reducing production costs and facilitating absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Accurately weigh 4mmol ferric chloride hexahydrate and disperse it in 20mL of absolute ethanol, and obtain a clear solution under the action of ultrasound. Slowly add 4mmol ionic liquid 1-butyl-3-methylimidazolium chloride [BMIM]Cl to the clear solution, stir vigorously for 30min, and then add 6mmol NaOH solid to it after it is fully dispersed, and continue magnetic stirring for 1h. The solution was transferred to a stainless steel autoclave lined with polytetrafluoroethylene (volume filling rate was 80%), and the autoclave was sealed. The autoclave was placed in an oven at 160° C. to react for 24 hours. After the reaction was completed, the autoclave was naturally cooled to room temperature. Centrifuge the product, wash it with deionized water and absolute ethanol for at least 5 times, and then place the product in a vacuum drying oven for 24 hours at 70°C to obtain Fe 2 o 3 nano ring.

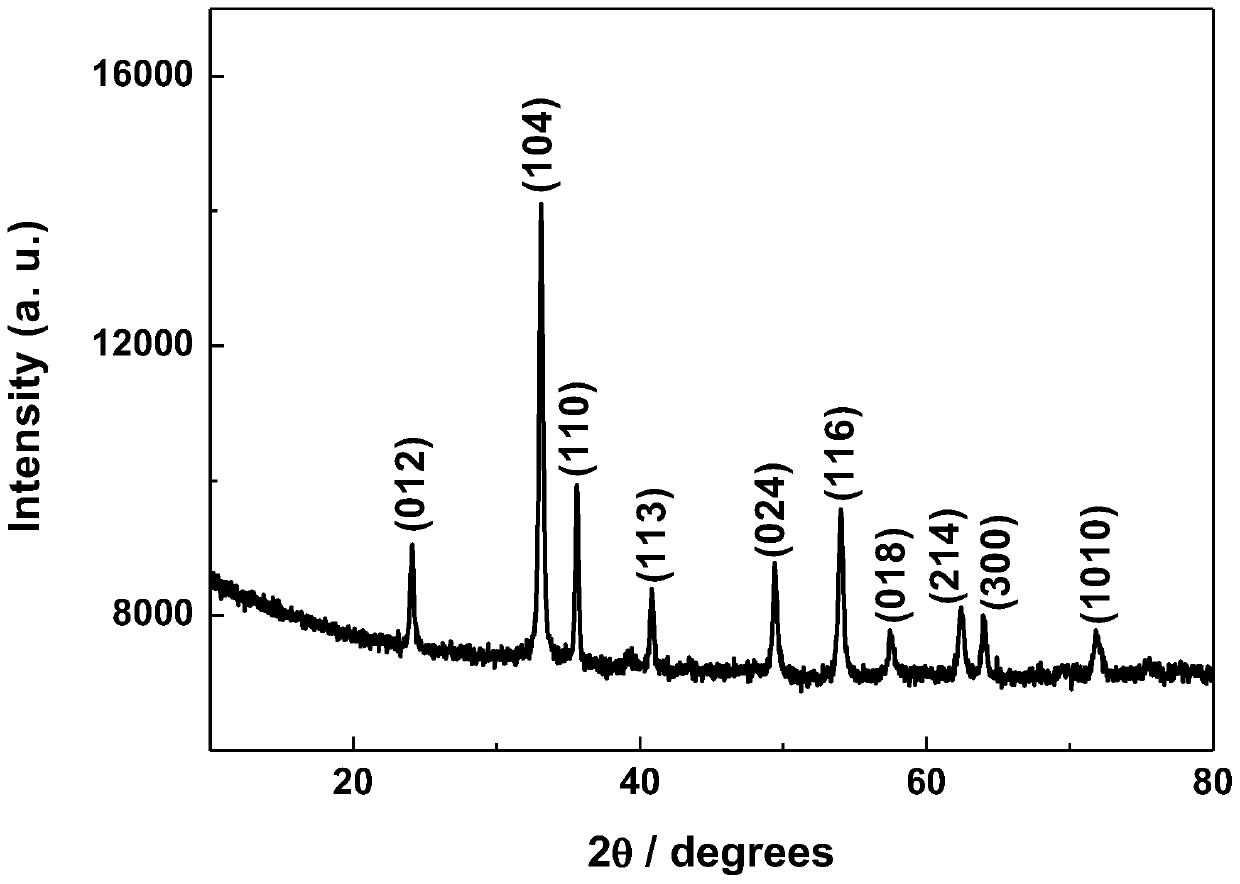

[0032] XRD pattern ( figure 1 ) can be attributed to the hexagonal rhombic str...

Embodiment 2-27

[0037] Adopt the consumption of ionic liquid [BMIM] Cl in Table 1 and other experimental conditions, according to the preparation process described in embodiment 1, change ferric chloride hexahydrate, ionic liquid and reaction temperature and reaction time, can obtain required Fe equally 2 o 3 Nanoring photocatalysts.

[0038] Table 1 Fe under different conditions 2 o 3 Nanoring preparation

[0039]

[0040]

[0041] Structure the finished nanorings prepared in the above examples. This synthesis method is simple to operate, has good repeatability, is easy to control the reaction, and has high yield. Product verification and catalytic performance experiments can confirm that it also has a hexagonal structure and is a hollow nanoring structure. The size is uniform, the dispersion is good, the surface of the product is porous, and the crystallinity is good. As a photocatalyst, the experiment of degrading methyl orange solution and various reactive dye solutions can obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com