Intelligent squeezing equipment based on data analysis and working method of intelligent equipment

A data analysis and working method technology, applied in the field of data analysis, can solve the problems of affecting the taste, nutrient loss, cumbersome steps, etc., and achieve the effect of easy cleaning of the knife net, ensuring safety and freshness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

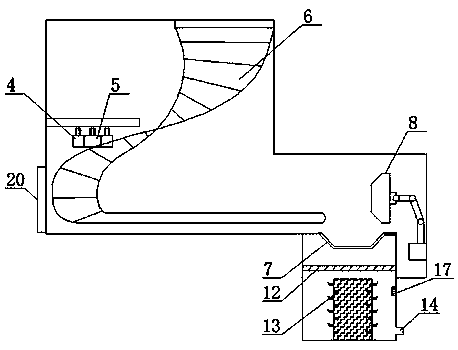

[0052] Such as Figure 1-7 As shown, the present embodiment provides an intelligent juicing device based on data analysis, including a cutting mechanism, a juicing mechanism, and a processing mechanism. The processing mechanism includes a processor 1, a driving device 2, and a storage device 3. The processor 1 They are respectively connected to the drive device 2 and the storage device 3 , and the storage device 3 is used to store the data sent by the processor 1 .

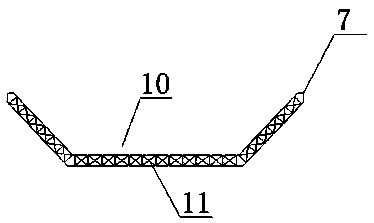

[0053] The cutting structure includes a first blade device 4, a second blade device 5, a transfer platform 6, a screening funnel 7, an extruding device 8 and a camera device 9, the second blade is set as a cylindrical blade, and the first blade is set as several straight plates The blade is evenly surrounded by the second blade, the first blade device 4 and the second blade device 5 are respectively connected to the drive device 2 for separating raw materials, and the transfer table 6 is connected to the drive dev...

Embodiment 2

[0072] Such as Figure 1-8 As shown, the present embodiment provides a working method of an intelligent juicing device based on data analysis, including the following working steps:

[0073] S101: The camera device 9 acquires the appearance state of the raw material and sends the captured image to the processor 1 .

[0074] S102: The processor 1 outputs a first transmission signal to the driving device 2, and the driving device 2 drives the transfer table 6 to transfer the raw materials on it to the first blade device 4 and the second blade device 5 directly below the .

[0075] S103: The processor 1 analyzes the type of the raw material and sets a corresponding cutting scheme and screening scheme;

[0076] S104: The processor 1 outputs a cutting signal to the driving device 2, and the driving device 2 drives the first blade device 4 and the second blade device 5 to perform cutting according to the cutting scheme.

[0077] S105: The processor 1 judges whether there are ined...

Embodiment 3

[0101] Such as Figure 1-9 As shown, this embodiment provides a seasoning method, the sugar content meter 17 detects the sugar content of the beverage in the juice extracting mechanism and sends it to the processor 1 .

[0102] The processor 1 judges whether the sugar content is greater than a preset sugar content set by the user.

[0103] If so, the processor 1 extracts the seasoning chamber 15 where the sour additive is located and the electric discharge valve 16 corresponding to the seasoning chamber 15, and outputs a second opening signal to the driving device 2, and the driving device 2 drives The electric discharge valve 16 is opened.

[0104] If not, the processor 1 extracts the seasoning chamber 15 where the sweetness additive is located and the electric discharge valve 16 corresponding to the seasoning chamber 15, and outputs a third opening signal to the driving device 2, and the driving device 2. Drive the electric discharge valve 16 to open.

[0105] Specificall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com