Preparation method of polyacrylic acid flexible composite hydrogel electrolyte

A polyacrylic acid flexible and composite hydrogel technology, which is applied in the manufacture of hybrid capacitor electrolytes and hybrid/electric double layer capacitors, can solve the problems of ionic conductivity and mechanical properties that cannot meet the needs of portable electronic products such as flexible bending performance, and achieve Good memory effect, easy operation and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

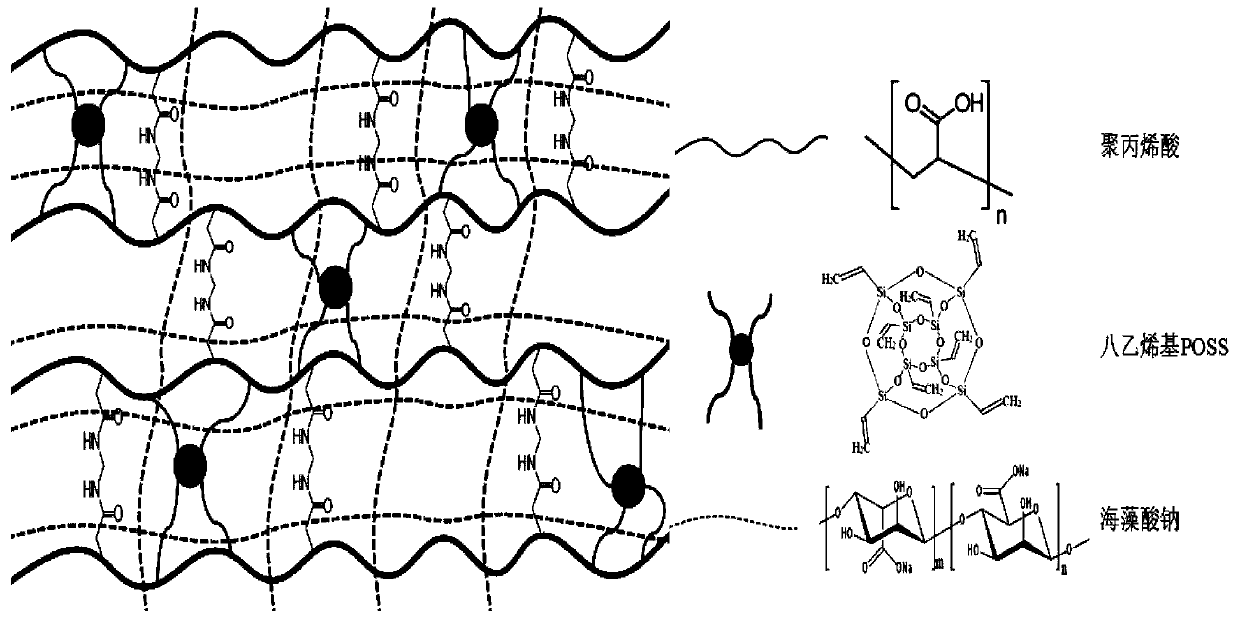

[0028] A preparation method of polyacrylic acid flexible composite hydrogel electrolyte, the steps are as follows:

[0029] (1) Dissolve 0.075g of sodium alginate in 10ml of distilled water, stir and use ultrasonic dispersion to form a solution, for use;

[0030] (2) Add 1.5 g acrylic acid, 0.0075 g N-N' methylene bisacrylamide, 0.03 g octavinyl POSS and 0.075 g OP-10 to the solution obtained in step (1), stir and use ultrasonic dispersion for 10 minutes;

[0031] (3) Add 0.0075g of ammonium persulfate to the solution obtained in step (2), stir and use ultrasonic dispersion for 10 minutes;

[0032] (4) The reaction system obtained in step (3) was allowed to stand for 5 hours in an oven at 60°C;

[0033] (5) Dry the hydrogel obtained in step (4) naturally for 36 hours;

[0034] (6) The hydrogel obtained in (5) was soaked in a 0.1 mmol / L phosphomolybdic acid solution for 18 hours to obtain a polyacrylic acid flexible composite hydrogel electrolyte.

Embodiment 2

[0036] A preparation method of polyacrylic acid flexible composite hydrogel electrolyte, which is different from Example 1 in that in step (1), 0.075g of sodium alginate is changed to 0.100g, and in step (2), 1.5g of acrylic acid is changed to 2.0g , 0.0075gN-N'methylenebisacrylamide becomes 0.0250g, 0.03g octavinyl POSS becomes 0.04g, 0.075gOP-10 becomes 0.100g, and in step (3) 0.0075g ammonium persulfate becomes 0.0200 g azobisisobutylamidine hydrochloride, in step (5), natural drying for 36h becomes 42h, in step (6), 0.1mmol / L phosphomolybdic acid becomes 0.2mmol / L phosphotungstic acid, step ( 6) Soak in 18h to 24h.

Embodiment 3

[0038] A preparation method of polyacrylic acid flexible composite hydrogel electrolyte, which is different from Example 1 in that in step (1), 0.075g of sodium alginate is changed to 0.200g, and in step (2), 1.5g of acrylic acid is changed to 2.0g , 0.0075gN-N'methylenebisacrylamide becomes 0.0250g, 0.03g octavinyl POSS becomes 0.10g, 0.075gOP-10 becomes 0.125g, and in step (3) 0.0075g ammonium persulfate becomes 0.0250 g, in step (5), natural drying for 36h becomes 48h, in step (6), the 0.1mmol / L phosphomolybdic acid becomes 0.3mmol / L p-benzoquinone, and in step (6), soaking for 18h becomes 30h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com