Hot water boiler control system applying PLC controller

A hot water boiler and control system technology, which is applied in general control systems, program control in sequence/logic controllers, control/regulation systems, etc., can solve the problem of low boiler fuel combustion rate and stability rate, and inability to adjust combustion in time , can not understand the temperature parameters and other issues, to achieve the effect of easy adjustment, improve the combustion rate and heat stability, and avoid the effect of artificial addition of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

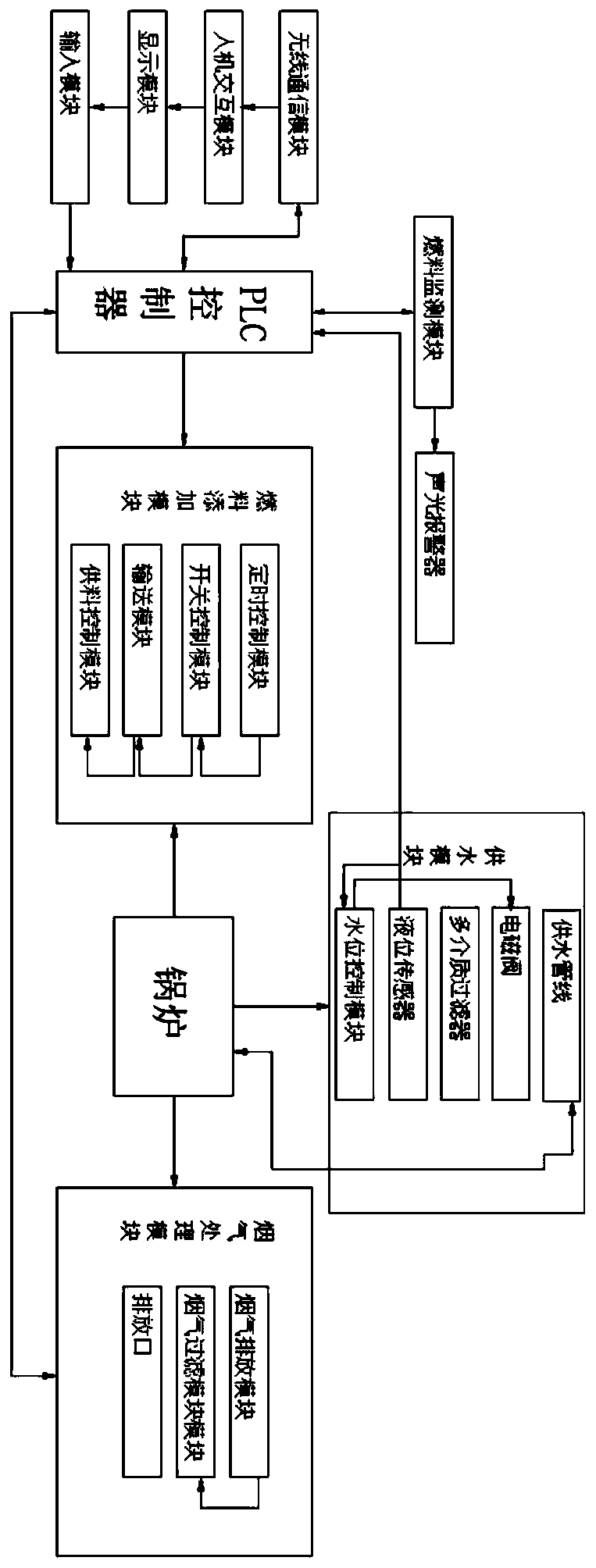

[0025] see figure 1 , the present invention provides a technical solution: a hot water boiler control system using a PLC controller, including a PLC controller, a fuel monitoring module, a fuel adding module, a water supply module, a flue gas treatment module, a boiler, a wireless communication module, a human machine interaction module, sound and light alarm, display module and input module, the human-computer interaction module is connected to the display module, the display module is connected to the input module, the input module is connected to the PLC controller, and the fuel adding module includes a timing control module, Switch control module, delivery module and material supply control module, water supply module includes water supply pipeline, solenoid valve, multimedia filter, liquid level sensor and water level control module, flue gas treatment module includes flue gas discharge module, flue gas filter module and discharge The fuel adding module is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com