Identification method of drilling fluid type and identification method of drilling and completion waste type

A drilling fluid and waste technology, which is used in the identification of drilling fluid types and the identification of drilling and completion waste types, can solve the problem of unreliable, unobtainable results or results, unsuitable drilling fluid and drilling and completion waste types identification and other problems, to achieve high reliability, small human influence factors, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0154] On August 21, 2017, a sample was taken at a depth of 3000m in the LN61-H2 well of Tarim Oilfield Company. The sample was polymer drilling fluid. The main components and mass content of the sample are as follows:

[0155]

[0156] The main physical properties of the drilling fluid are as follows:

[0157]

[0158] According to the above step 1, the liquid phase content of the drilling fluid is determined to be 94% (s=0.94), and the high temperature and high pressure filtrate of the drilling fluid is obtained.

[0159] According to above-mentioned step 2, the obtained high temperature and high pressure filtrate is detected, wherein:

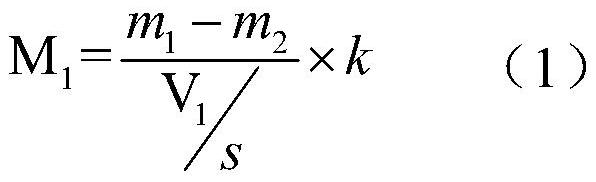

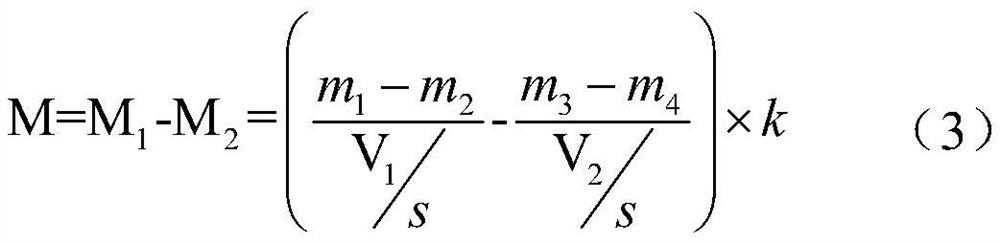

[0160] When measuring total sulfur, the mass of barium sulfate plus crucible m 1 is 33486.4mg, the mass of the crucible m 2 is 32799.3mg, then the mass of total sulfur in the high-temperature and high-pressure filtrate (based on barium sulfate mass, the same below) is 687.1mg;

Embodiment 2

[0166] On September 8, 2017, a sample was taken at a depth of 1238.13m in Well Tudong 201 of Tarim Oilfield Company. The sample was polymer drilling fluid. The main components and mass content of the sample are as follows:

[0167]

[0168] The main physical properties of the sample are as follows:

[0169]

[0170] According to the above step 1, the liquid phase content of the drilling fluid is determined to be 92%, and the high temperature and high pressure filtrate of the drilling fluid is obtained.

[0171] The high-temperature and high-pressure filtrate was detected according to the above-mentioned step two, and the free sulfate radical mass in the high-temperature and high-pressure filtrate was measured to be 89.9 mg, and the total sulfur mass was 569.2 mg. According to calculation, the sulfo group content in the drilling fluid is 19.45 mg / mL.

[0172] The drilling fluid was tested according to the above step 3, and the asphalt content was not detected.

[0173] ...

Embodiment 3

[0175] On August 30, 2017, a sample was taken at a depth of 4820.64m in Well YD705H of Tarim Oilfield Company. The sample was sulfonated drilling fluid. The main components and mass content of the sample are as follows:

[0176]

[0177] The main physical properties of the sample are as follows:

[0178]

[0179] According to the above step 1, the liquid phase content of the drilling fluid is determined to be 72%, and the high temperature and high pressure filtrate of the drilling fluid is obtained.

[0180] The high-temperature and high-pressure filtrate was tested according to the above-mentioned step 2, and the mass of free sulfate in the high-temperature and high-pressure filtrate was measured to be 182.3 mg, and the mass of total sulfur was 2064.5 mg. After calculation, the content of sulfo groups in the drilling fluid was 59.79 mg / mL.

[0181] The drilling fluid was tested according to the above step 3, and the asphalt content was 3.27mg / mL.

[0182] According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com