High-strength magnesium alloy

A magnesium alloy, high-strength technology, applied in the field of magnesium alloys, can solve the problems of restricting widespread use, magnesium alloys are easy to be corroded, and aggravated corrosion, so as to improve flame retardancy, improve thermal conductivity and strength, and avoid oxidative combustion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

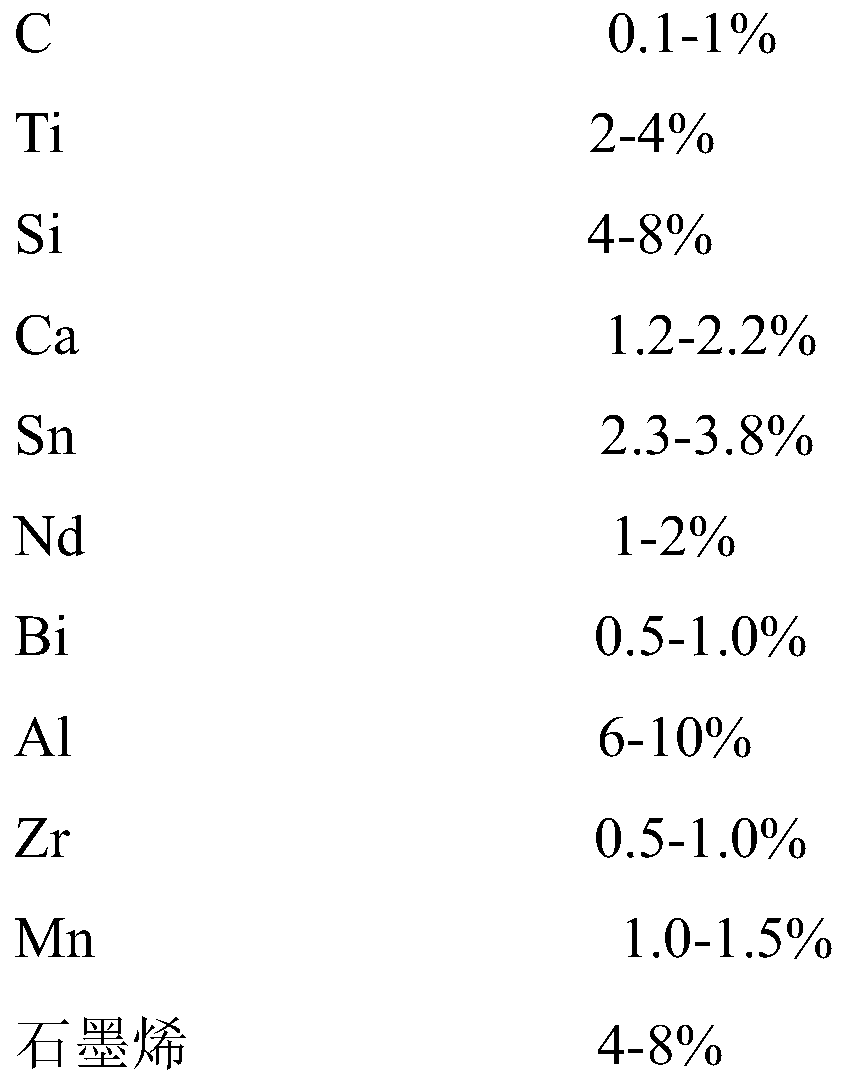

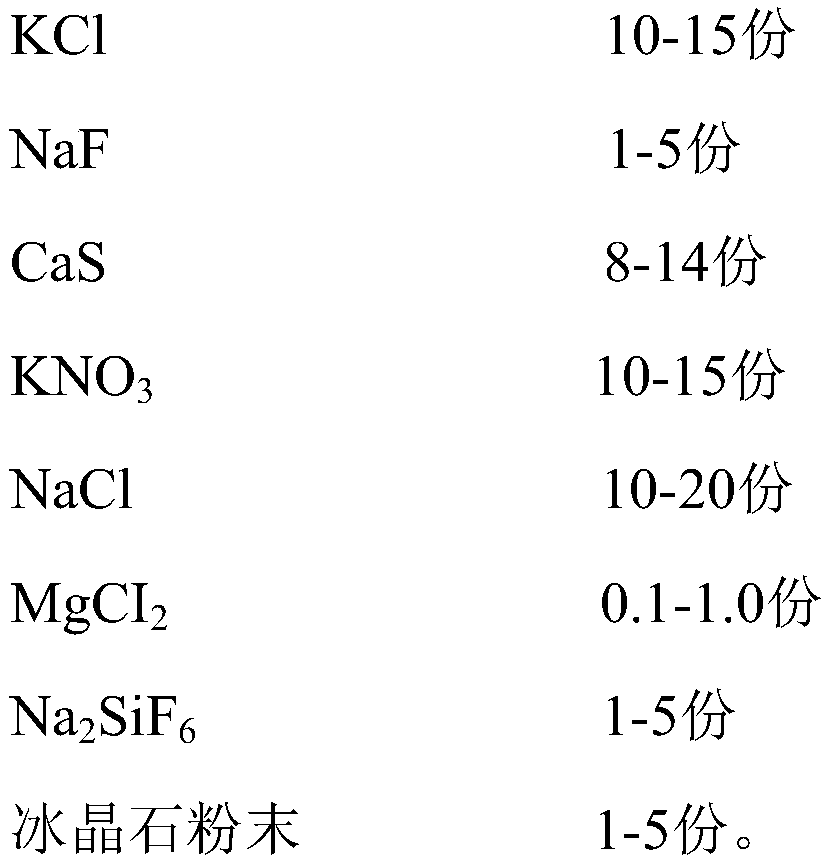

[0028] A high-strength magnesium alloy, comprising raw materials in the following weight percentages:

[0029]

[0030]

[0031] The high-strength magnesium alloy is prepared by the following method:

[0032] 1) According to weight percentage, pure Mg, pure C, pure Bi, CaCl 2 , SiO 2 , Mg-Nd master alloy, Mg-Ti-Sn master alloy, Ti-Al master alloy and Mg-Mn-Zr master alloy are used as raw materials for batching; Mg in pure Mg, Mg in Mg-Nd master alloy, Mg- The weight ratio of Mg in the Ti-Sn master alloy to Mg in the Mg-Mn-Zr master alloy is 0.8:0.4:0.1:0.6; the weight ratio of Ti in the Ti-Al master alloy to that in the Mg-Ti-Sn master alloy is 0.8:0.4;

[0033] 2) Put the pure Mg ingot into the refining equipment, heat it to 650°C under the condition of protective gas to melt until it is completely melted, add the refining agent and continue the heat preservation and melting for 10 minutes to obtain the molten slurry A, and then sequentially add pure Mg, pure C, Add M...

Embodiment 2

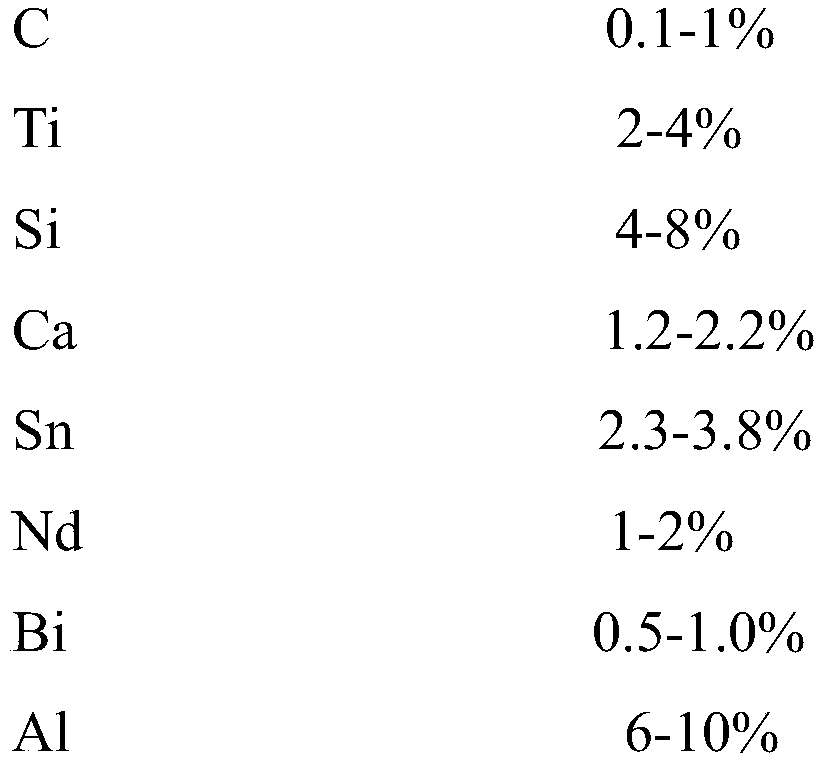

[0045] A high-strength magnesium alloy, comprising raw materials in the following weight percentages:

[0046]

[0047] The high-strength magnesium alloy is prepared by the following method:

[0048] 1) According to weight percentage, pure Mg, pure C, pure Bi, CaCl 2 , SiO 2 , Mg-Nd master alloy, Mg-Ti-Sn master alloy, Ti-Al master alloy and Mg-Mn-Zr master alloy are used as raw materials for batching; Mg in pure Mg, Mg in Mg-Nd master alloy, Mg- The weight ratio of Mg in the Ti-Sn master alloy to Mg in the Mg-Mn-Zr master alloy is 0.9:0.5:0.2:0.7; the weight ratio of Ti in the Ti-Al master alloy to that in the Mg-Ti-Sn master alloy is 0.9:0.5;

[0049] 2) Put the pure Mg ingot into the refining equipment, heat it to 675°C under the condition of protective gas to melt until it is completely melted, add the refining agent and continue the heat preservation and melting for 13 minutes to obtain the molten slurry A, and then sequentially add pure Mg, pure C, Add Mg-Nd maste...

Embodiment 3

[0061] A high-strength magnesium alloy, comprising raw materials in the following weight percentages:

[0062]

[0063] The high-strength magnesium alloy is prepared by the following method:

[0064] 1) According to weight percentage, pure Mg, pure C, pure Bi, CaCl 2 , SiO 2 , Mg-Nd master alloy, Mg-Ti-Sn master alloy, Ti-Al master alloy and Mg-Mn-Zr master alloy are used as raw materials for batching; Mg in pure Mg, Mg in Mg-Nd master alloy, Mg- The weight ratio of Mg in the Ti-Sn master alloy to Mg in the Mg-Mn-Zr master alloy is 1.0:0.6:0.3:0.8; the weight ratio of Ti in the Ti-Al master alloy to that in the Mg-Ti-Sn master alloy is 1.0:0.6;

[0065] 2) Put the pure Mg ingot into the refining equipment, heat it to 700°C under the condition of protective gas to melt until it is completely melted, add the refining agent and continue the heat preservation and melting for 15 minutes to obtain the molten slurry A, and then sequentially add pure Mg, pure C, Add Mg-Nd maste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com