High-nitrogen steel composite welding device and method for reducing porosity assisted by mechanical vibration

A composite welding and mechanical vibration technology, applied in welding equipment, laser welding equipment, welding/welding/cutting items, etc., can solve the problems of low welding quality and easy gas generation, achieve flexible process, improve interface connection strength, Effect of reducing welding distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

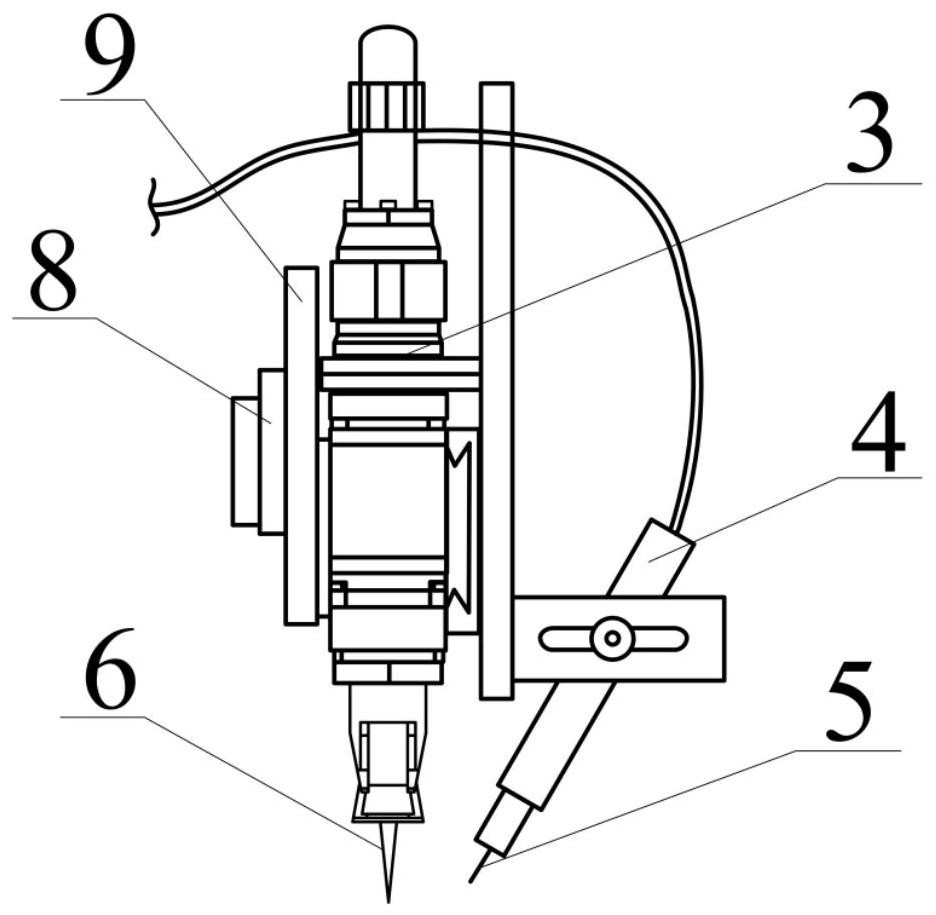

[0073] Example 1: Mechanical vibration assists in reducing porosity in composite welding of 8mm thick high nitrogen steel

[0074] Use an angle grinder to remove the oxide film on the surface of the two high-nitrogen steel plates to be welded, and then use acetone to remove the surface oil;

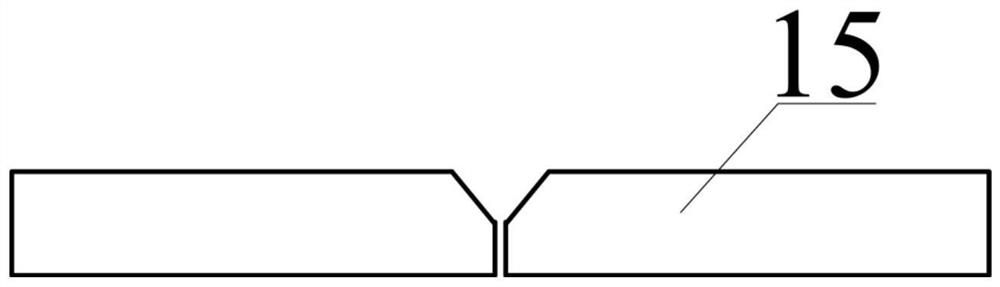

[0075] Install and debug the device, clamp the two high-nitrogen steel plates to be welded on the welding table in the form of butt joint, prefabricate the 30° groove and 4mm blunt edge of the high-nitrogen steel plate to be welded, and prefabricate the welding gap between the two plates of the workpiece to be welded. 0.8mm;

[0076]Apply mechanical vibration under the high-nitrogen steel plate to be welded, and use laser vertical irradiation welding above the metal material to be welded. The laser power is 3KW, and the defocus of the laser beam is -2mm; the welding torch is welded on the front of the welding workpiece, and the type of welding torch is MIG. ; The arc welding current of t...

Embodiment 2

[0078] Example 2: Mechanical vibration assists in reducing porosity in composite welding of 12 mm thick high nitrogen steel

[0079] Use an angle grinder to remove the oxide film on the surface of the two high-nitrogen steel plates to be welded, and then use acetone to remove the surface oil;

[0080] Install and debug the device, clamp the two high-nitrogen steel plates to be welded on the welding table in the form of butt joint, prefabricate the 30° groove and 5mm blunt edge of the high-nitrogen steel plate to be welded, and prefabricate the welding gap between the two plates of the workpiece to be welded. 0.6mm;

[0081] Apply mechanical vibration under the high-nitrogen steel plate to be welded, and use laser vertical irradiation welding above the metal material to be welded. The laser power is 4KW, and the defocus of the laser beam is -2mm; the welding torch is welded on the front of the welding workpiece, and the type of welding torch is MIG. ; The arc welding current o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com