Straw processing device

The technology of a straw briquetting machine and frame, which is applied in the field of agricultural science and technology, can solve the problems of low degree of crushing of straw and affecting the quality of straw briquetting, and achieve the effects of increasing the scope of application, improving the quality of grinding, and improving the quality of rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

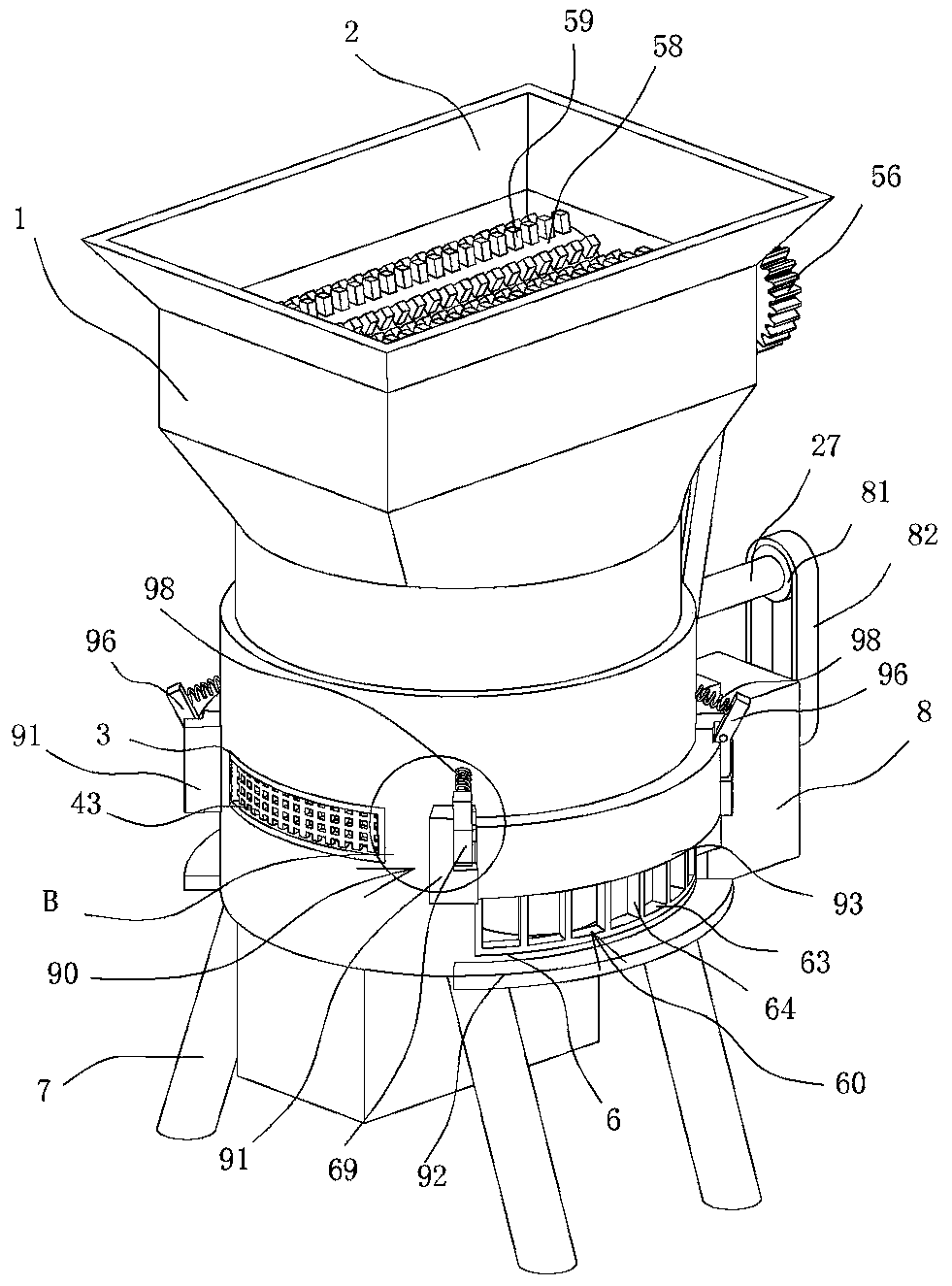

[0027] Such as figure 1 and figure 2 As shown, the straw processing equipment of the present invention includes a frame 1, the upper end of the frame 1 is provided with a material inlet 2, four evenly distributed legs 7 are provided under the frame 1, and the left and right sides of the frame 1 are provided with first outlets. Material port 6, the front end of frame 1 is provided with the second discharge port 8, and the inner lower end of frame 1 is provided with power mechanism 10, and power mechanism 10 upper side is provided with grinding mechanism 20, is provided with cutting mechanism 40 in the middle of power mechanism 10, power The upper end of the mechanism 10 is provided with a briquetting mechanism 60 that squeezes the straw fragments into pieces, the first discharge port 6 is provided with a stopper mechanism 90, the stopper mechanism 90 is arranged on the outside of the briquetting mechanism 60, and the upper side of the grinding mechanism 20 is set There is a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com