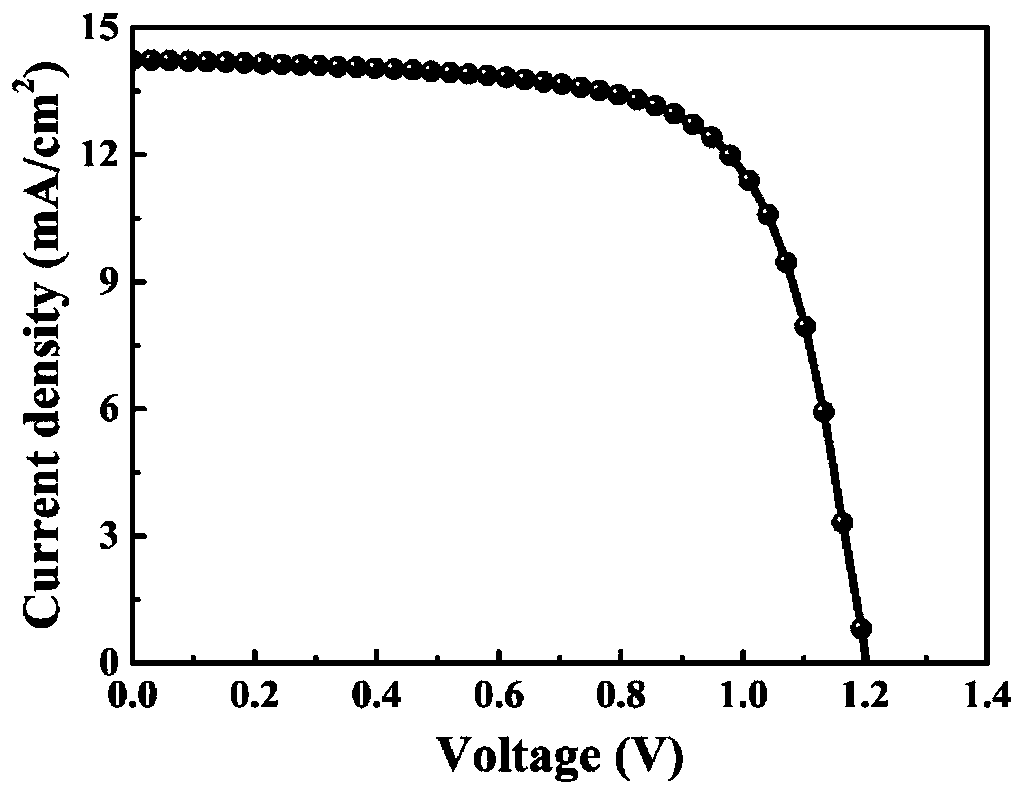

Carbon-based perovskite solar cell based on multifunctional interface modification layer

An interface modification layer, solar cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of interface contact and recombination, non-radiative recombination of light absorbing layer, instability, etc., and achieve high power conversion efficiency and good stability. , the effect of high repetition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Preparation of electron transport layer:

[0035] 15wt.% SnO 2 The colloidal dispersion was diluted to 2.67wt.%, and coated on clean ITO conductive glass by spin coating, and a dense layer of SnO was formed after annealing at 150°C for 30min. 2 Thin film (30nm thickness).

[0036] 2) Preparation of alkali metal hydroxide layer:

[0037] Dissolve KOH powder (>99.99%) in deionized water and prepare a 20mM aqueous solution. After stirring for 1-2h, take 60uL and spin-coat the SnO in step 1). 2 On the film, a dense KOH film (5nm thickness) was formed after annealing at 100°C for 10 minutes.

[0038] 3) Preparation of perovskite layer:

[0039] Add cesium bromide and lead iodide into DMSO at a molar ratio of 1:1, stir for 1 h, and prepare a perovskite solution with a molar content of 1.0. After stirring for 12 h at room temperature, a clear and transparent yellow perovskite precursor solution was obtained. In the glove box, take 50uL precursor solution and adopt one...

Embodiment 2

[0047] Example 2 of the present invention is basically the same as Example 1, except that KOH is replaced by NaOH.

[0048] 1) Preparation of electron transport layer:

[0049] 15wt.% SnO 2 The colloidal dispersion was diluted to 2.67wt.%, and coated on a clean FTO conductive glass by spin coating, and a dense layer of SnO was formed after annealing at 150°C for 30 minutes. 2 film.

[0050] 2) Preparation of alkali metal hydroxide layer:

[0051] Dissolve NaOH powder (>99.99%) in deionized water to prepare a 10mM aqueous solution. After stirring for 1-2h, take 60uL and spin-coat the SnO in step 1). 2 On the film, a dense NaOH film was formed after annealing at 100°C for 10 min.

[0052] 3) Preparation of perovskite layer:

[0053] Add cesium bromide and lead iodide into DMSO at a molar ratio of 1:1, stir for 1 h, and prepare a perovskite solution with a molar content of 0.8. After stirring for 12 h at room temperature, a clear and transparent yellow perovskite precursor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com