Method for detecting defects of screen printing area of smart phone glass cover plate based on machine vision

A glass cover, smartphone technology, applied in the field of visual inspection, can solve problems such as reliability dependence, and achieve the effect of accurate acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

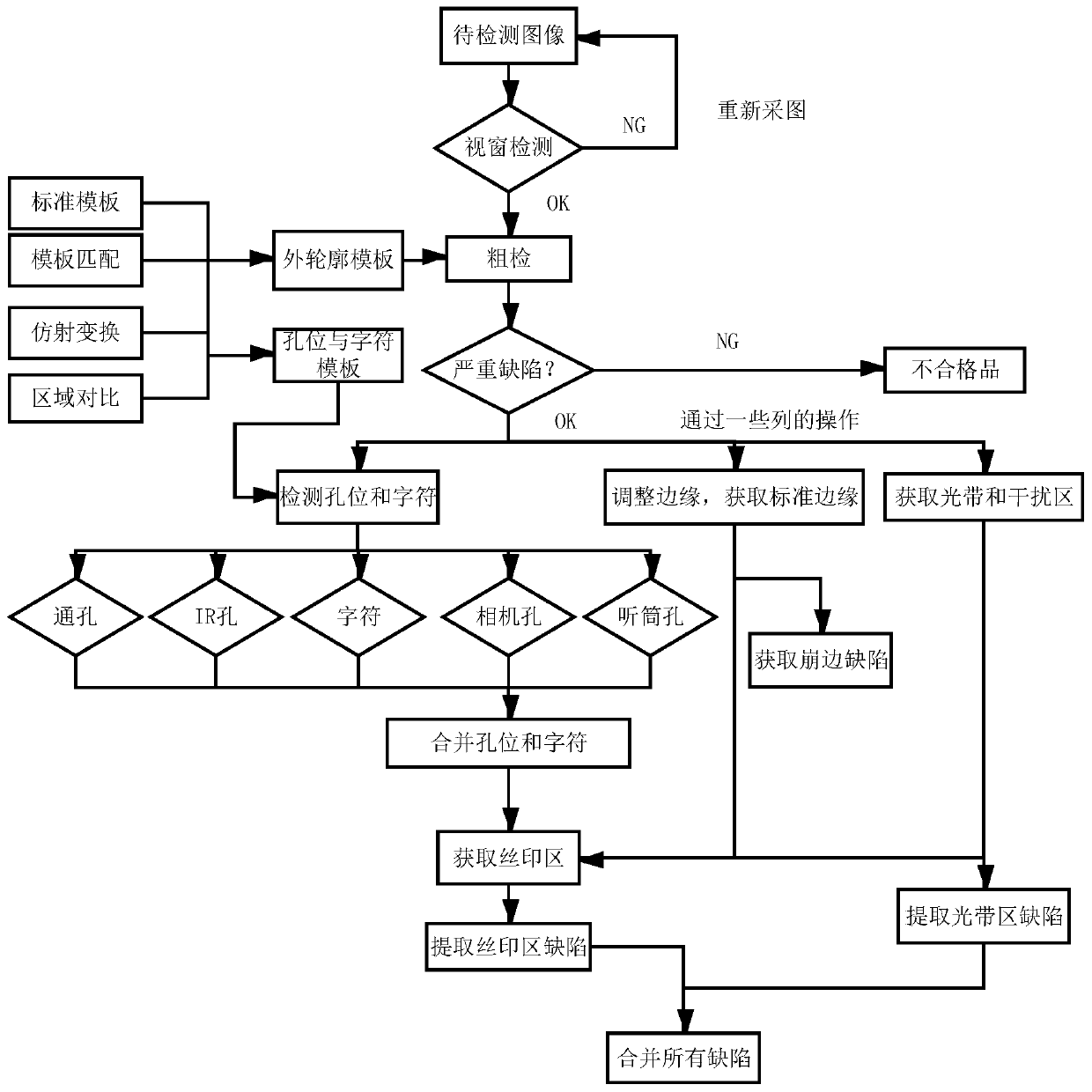

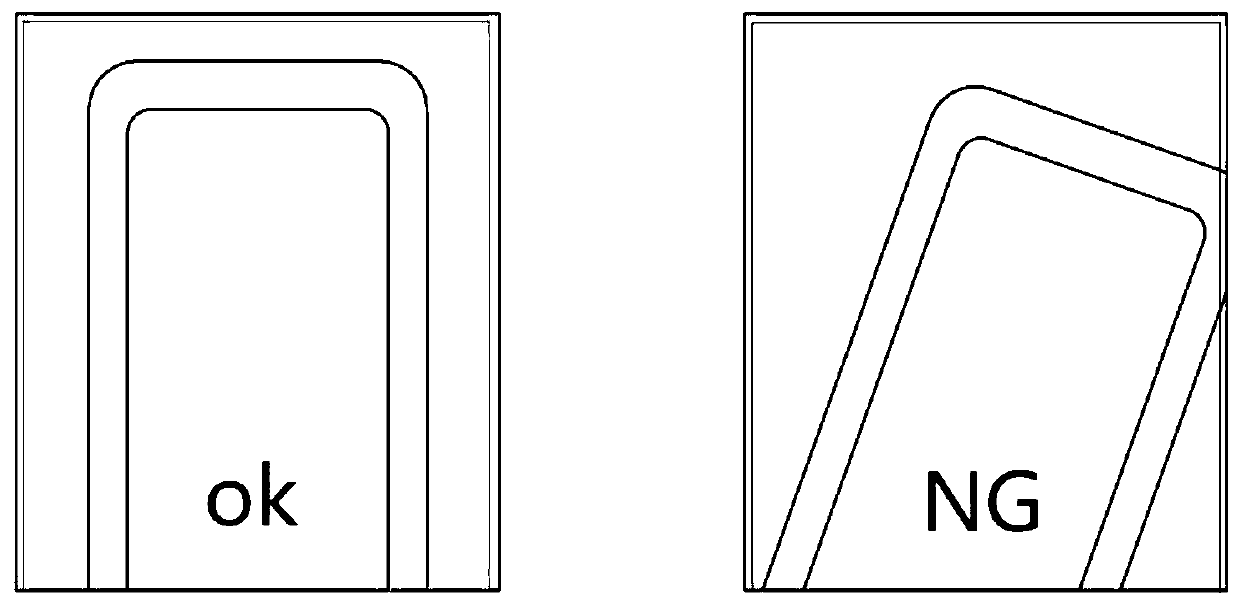

[0082] figure 1 It is a schematic diagram of the defect extraction process of the present invention. A method for detecting defects in the screen printing area of a smartphone glass cover based on machine vision, including the following steps:

[0083] S1. Capture the image of the mobile phone glass cover: Use a 16K line-scan camera to collect images of the upper half and the lower half of the mobile phone cover. The size is about 2 / 3 of the entire mobile phone screen, and the image resolution is 40000×16384. The detection accuracy can reach 0.005mm.

[0084] S2. Read relevant parameter information, including the template information of the outer contour, the upper and lower limits of the global threshold, the size information of the mobile phone cover, the informati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com