A kind of nanoparticle uniformly dispersed aluminum-based intermediate and its preparation and application method

A nanoparticle, uniformly dispersed technology, applied in the field of iron and steel metallurgy, can solve the problems of nanoparticle agglomeration and low yield, and achieve the effects of ensuring stable yield, improving wettability, and eliminating steel performance hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

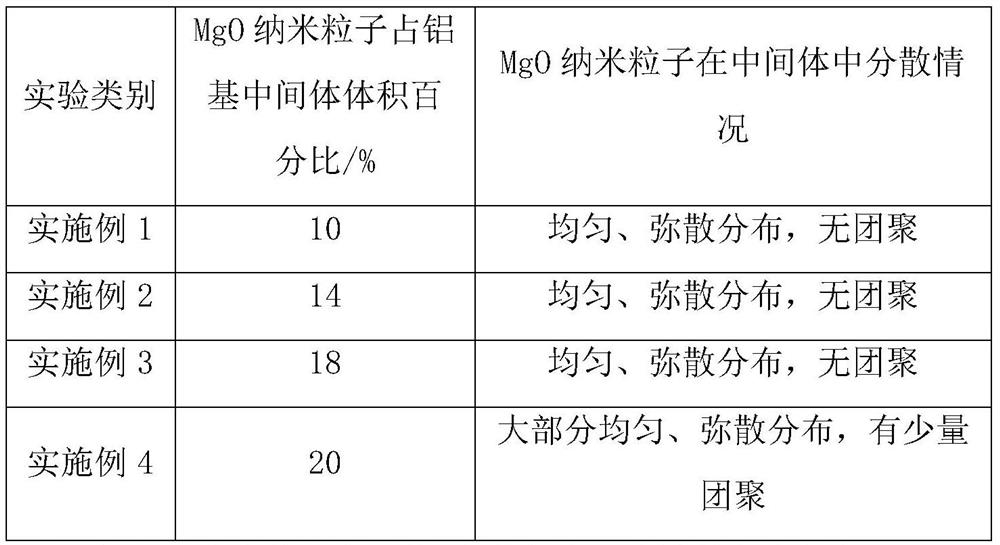

Embodiment 1

[0035] A method for preparing an aluminum-based intermediate evenly dispersed by nanoparticles, comprising the following steps:

[0036] (1) Weigh MgO nanopowder and pure aluminum block according to the volume ratio of 1:9. The pure aluminum block is placed in a graphite crucible and then placed in an intermediate frequency induction furnace, heated by electricity, when the melt temperature rises to 880°C, it is kept at this temperature, and carbonized rice husk is used as a covering agent in the remelting process.

[0037] (2) The molten aluminum is melted and slag removed, the graphite crucible is taken out and put into a spiral electromagnetic stirrer, the stirring current is set to 100A, and the frequency is 30Hz. Immerse the ultrasonic transmitter head in the aluminum liquid through the lifting device to a depth of 30mm to preheat. After preheating for 8 minutes, set the output power of the ultrasonic processor to 0.8kW and the frequency to 20Hz.

[0038](3) Turn on the ...

Embodiment 2

[0041] A preparation method for uniformly dispersing aluminum-based intermediates with nanoparticles. The basic experimental steps of this example are the same as those in Example 1, except that MgO nanopowder is dispersed into aluminum liquid at a volume ratio of 1:6 to prepare a volume The fraction is about 14% MgO nanopowder aluminum based intermediate. The output power of the ultrasonic processor is 0.86kW, the current of the spiral electromagnetic stirrer is 180A, the frequency is 38Hz, and the other parameters are the same as in Embodiment 1.

Embodiment 3

[0043] A preparation method for uniformly dispersing aluminum-based intermediates with nanoparticles, the basic experimental steps of this embodiment are the same as those in Example 1, the difference is that MgO nano powder is dispersed into aluminum liquid at a volume ratio of 1:4.5, and prepared into a volume The fraction is about 18% MgO nanopowder aluminum based intermediate. The output power of the ultrasonic processor is 0.92kW, the current of the spiral electromagnetic stirrer is 250A, the frequency is 45Hz, and the other parameters are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com