Titanium dioxide for plastics and ink and preparation method thereof

A technology of titanium dioxide and ink, applied in the direction of ink, chemical instruments and methods, applications, etc., can solve the problems of reduced weather resistance, high production cost, and damage to the continuity of products, so as to improve weather resistance, gloss, lubricity and The effect of good fluidity and excellent dry powder fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

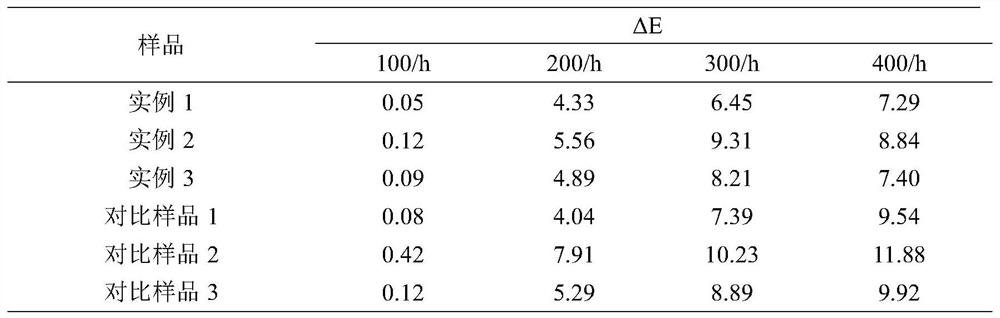

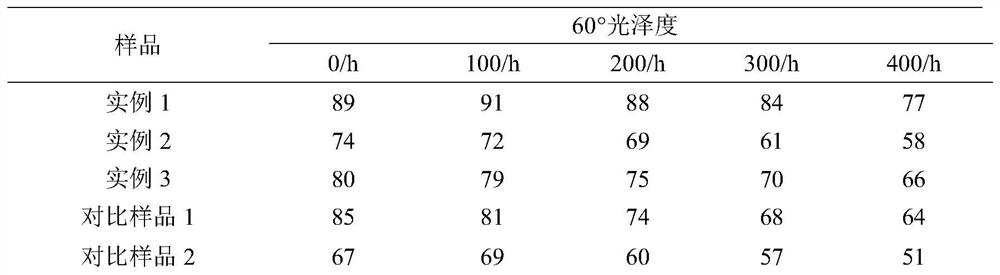

Examples

preparation example Construction

[0028] Specifically, the preparation method of titanium dioxide for plastics and printing inks comprises the following steps:

[0029] S1. Pretreatment: Add sodium silicate solution into water, then add rutile titanium dioxide to beat and disperse to obtain a titanium dioxide slurry with a concentration of 300-800g / L; grind and classify the titanium dioxide slurry to obtain a titanium dioxide particle size D50 of 0.25- 0.45μm, D90≤0.8μm titanium dioxide slurry;

[0030] S2. Inorganic coating:

[0031] ①Coating zinc oxide: control the temperature of the titanium dioxide slurry obtained in step S1 to 55-75°C, and add zinc salt solution and alkali solution at a constant speed for 60-180 minutes to maintain the pH of the slurry at 8.0-10.0, and react for 60-120 minutes; The temperature of the slurry system in the zinc oxide coating process is maintained at 55-75°C; the amount of the zinc salt solution added is calculated as the TiO in the slurry in terms of ZnO 2 0.5~1.5% of mas...

Embodiment 1

[0044] Add prepared sodium silicate dispersant to deionized water, then add rutile titanium dioxide particles, perform beating and dispersion treatment, and obtain titanium dioxide slurry with a concentration of 600g / L. The titanium dioxide slurry was subjected to wet grinding, and the ground slurry was classified to obtain the classified slurry: the particle size D50 of the titanium dioxide particles in the slurry was 0.35 μm, and the D90 was 0.75 μm. Put the slurry into the coating equipment with stirring device, start the stirring device, heat and maintain the temperature of the slurry at 60°C; add zinc chloride with a concentration of 100g / L to the slurry at a constant speed and co-current within 100 minutes Solution and a sodium hydroxide solution with a mass fraction of 15%, maintain the pH value of the slurry at 8.0 to 10.0, and the amount of zinc chloride solution added is calculated as ZnO in the slurry TiO 2 1.0% of the mass, react for 100 minutes; add a sodium metaa...

Embodiment 2

[0046] Add prepared sodium silicate dispersant to deionized water, then add rutile titanium dioxide particles, perform beating and dispersion treatment, and obtain titanium dioxide slurry with a concentration of 600g / L. The titanium dioxide slurry was subjected to wet grinding, and the ground slurry was classified to obtain the classified slurry: the particle size D50 of the titanium dioxide particles in the slurry was 0.35 μm, and the D90 was 0.75 μm. Put the slurry into the coating equipment with stirring device, start the stirring device, heat and maintain the temperature of the slurry at 60°C; add zinc chloride with a concentration of 150g / L to the slurry at a uniform speed and co-current within 60 minutes Solution and a sodium hydroxide solution with a mass fraction of 15%, maintain the pH value of the slurry at 8.0 to 10.0, and the amount of zinc chloride solution added is calculated as ZnO in the slurry TiO 2 0.5% of the mass, react for 60 minutes; add a sodium metaalum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com