Ternary conjugated polymer thermoelectric material with different side chain polarities, and preparation method and application thereof

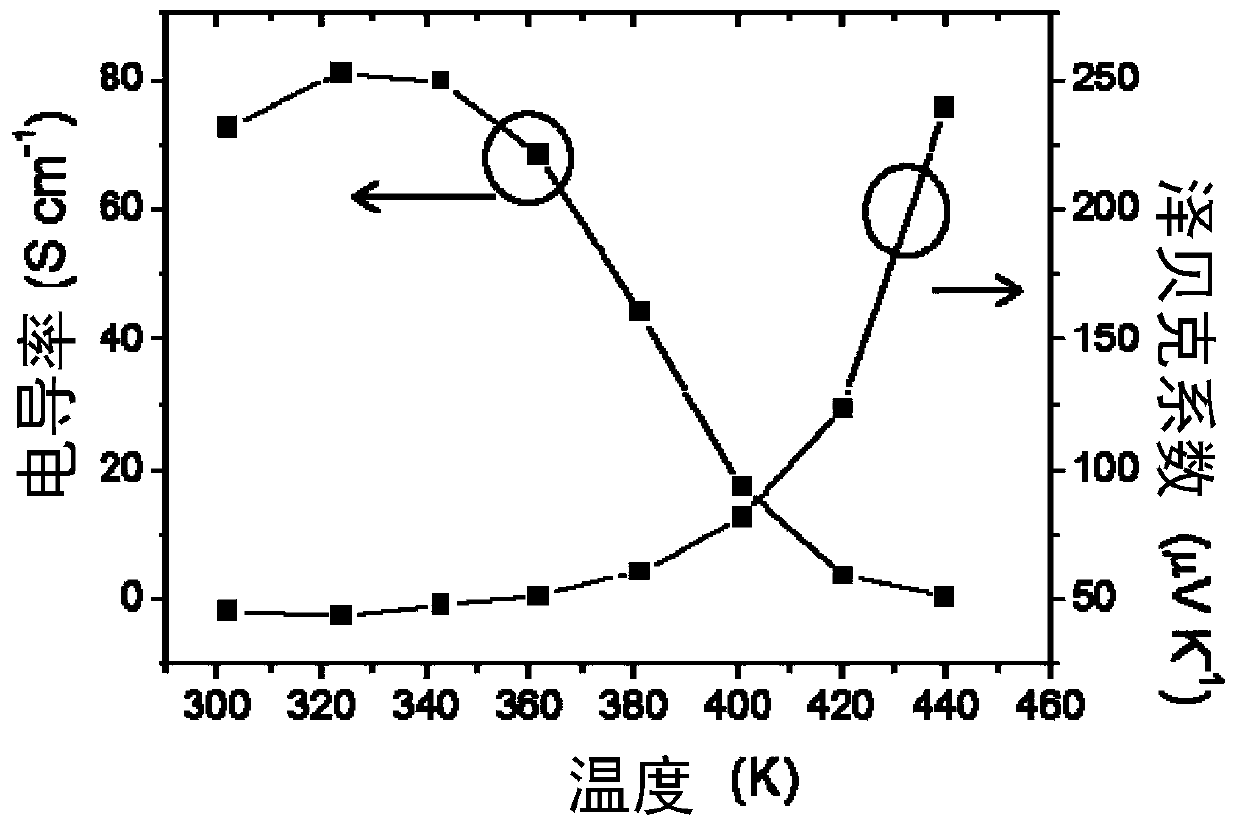

A technology of conjugated polymers and compounds, applied in the field of polymer thermoelectric materials, can solve the problems of difficult to explain the regulation mechanism, not universal, and cumbersome preparation process, and achieve high power factor, moderate Seebeck coefficient, and promising application prospects broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] In one embodiment of the present invention, the preparation method of an alternating conjugated polymer based on diketopyrrolopyrrole and ethoxy-substituted bithiophene comprises the following steps: compound 1 and compound 2 are carried out under the conditions of an inert atmosphere and the presence of a catalyst For the copolymerization reaction, the polymerization method uses Stille coupling to obtain the polymer shown in formula II. The preparation method of the alternating conjugated polymer based on diketopyrrolopyrrole and ethoxy-substituted bithiophene is exemplarily described below.

[0070] Will equimolar amount with R 1 , R 2 The diketopyrrolopyrrole diketopyrrolopyrrole dibromo substituent and the ethoxy-substituted bithienstannane substituent are put into a reaction bottle, and an inert gas is passed.

[0071] Continue to add anhydrous chlorobenzene in the reaction bottle, fill with nitrogen after vacuumizing, stir for a certain period of time (for examp...

Embodiment 1

[0081] Terpolymer shown in the preparation formula Ⅰ-1, wherein R 1 and R 2 Both are 2-octyl-dodecyl, k is 3, m is 0.7, 0.5, 0.3 respectively;

[0082]

[0083] The specific steps and conditions of the above-mentioned polymerization reaction are as follows:

[0084] (1) According to the method disclosed by Iain McCulloch (J.Am.Chem.Soc.2011,133,3272-3275), the synthesized 2,5-di(2-octyldodecyl)-3,6- Bis(5-bromothienyl-2-)-diketopyrrolopyrrole (122.3 mg) was added to the polymerization bottle, and then ethoxylate synthesized according to the method published by Christian Müller (Adv. Base thiophene (33.4 mg), add trimethylstannothiophene (80.2 mg), add 6 milliliters of chlorobenzene, vacuum deoxygenate, fill with argon, then add palladium catalyst (2.0 mg), phosphorus ligand (2.1 milligrams), vacuumized and filled with argon again, the solution was heated to 110°C, stirred and reacted for 48 hours, and a polymer with m of 0.7 was obtained. After the reaction was complete...

Embodiment 2

[0089] The polymer material provided by the invention and 2,3,5,6-tetrafluoro-7,7',8,8'-tetracyanodimethyl-p-benzoquinone are mixed by using a liquid phase chemical doping method. The polymer obtained in Example 1 was dissolved in chlorobenzene to prepare a 5 mg / mL solution, and 2,3,5,6-tetrafluoro-7,7',8,8'-tetracyanodimethyl Benzoquinone was dissolved in chlorobenzene to obtain a 2 mg / mL solution. The polymer solution described in formula I-1 and the dopant solution were mixed according to a mass ratio of 3:1 to obtain a doped solution composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com