Whole-body dry-pressed porcelain induction cooker heating panel material and preparation method thereof

A technology for heating panels and induction cookers, which is applied to clay products, other household appliances, and household appliances. It can solve the problems of rough materials, easy breakage, and low product strength, and achieve the effects of enhanced molding ability and good electromagnetic wave penetration performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0113] The present invention will be described in further detail below in conjunction with embodiment:

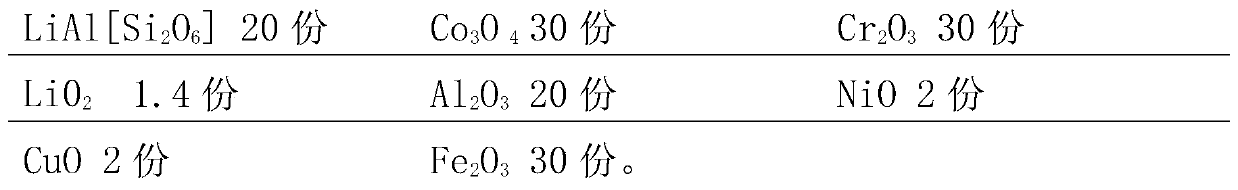

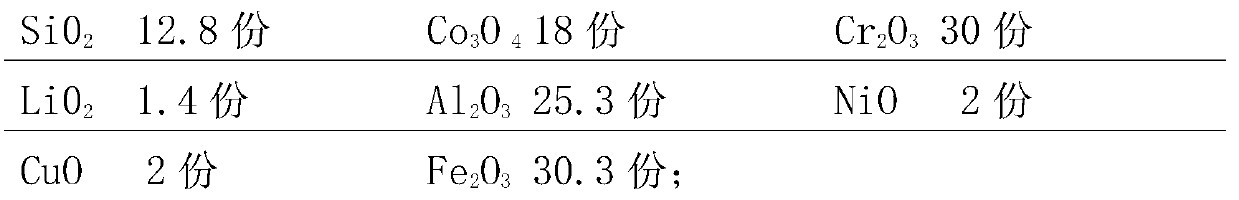

[0114] The whole body dry-pressed porcelain induction cooker heats panel materials, and the panel blank is composed of the following components by weight:

[0115] 30 parts of spodumene, 15 parts of cordierite, 6 parts of calcined kaolin

[0116] 30 parts of kaolin, 15 parts of fused quartz, 5 parts of petalite

[0117] 4 parts of colorant;

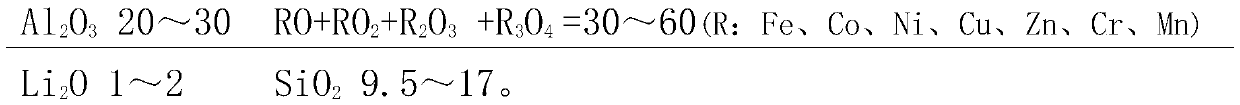

[0118] The chemical composition of the panel blank consists of the following components in parts by weight:

[0119] Li 2 O 2.43 parts K 2 O+Na 2 O<0.54 parts CaO<0.11 parts

[0120] MgO 2.05 parts Al 2 o 3 27.5 parts Si 2 O 63.23 parts

[0121] Fe 2 o 3 0.45 TiO 2 0.27 parts plus 4% parts of black material

[0122] The panel glaze consists of the following components in parts by weight:

[0123] 47 parts of spodumene, 5 parts of petalite, 3 parts of barium carbonate

[0124] Calcite 7 parts Fused quartz 28 parts Kao...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com