Preparation method and propane oxydehydrogenation application of rodlike hexagonal boron nitride foam

A technology of hexagonal boron nitride and foam, which is applied in the fields of material science and technology and petrochemical industry, and can solve problems such as affecting efficiency, difficult to control catalytic reaction, and large pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

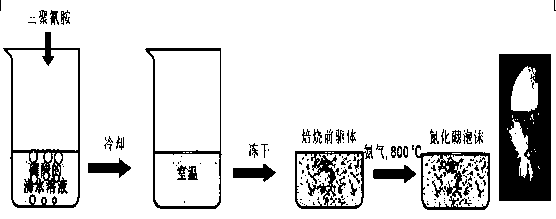

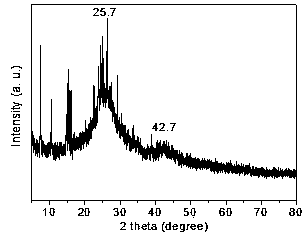

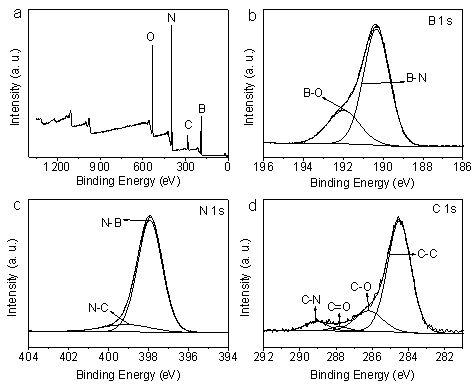

[0029] 2.47 g of boric acid was dissolved in 100 mL of ultrapure water, boiled, and 2.50 g of melamine was added several times to completely dissolve until transparent, then naturally cooled to room temperature, and a white hydrogel was precipitated. The white hydrogel was vacuumed at -20°C until lyophilized, transferred to a crucible, and placed in a tube furnace. Under an ammonia atmosphere, the flow rate was 80 mL / min, the temperature was raised at 5 °C / min, and the temperature was kept at 800 °C for 5 h, and then cooled naturally to obtain a white foam sample, that is, a rod-shaped hexagonal boron nitride foam material.

[0030] Take 30 mg of foam material and place it in a U-shaped tube, and fix it with quartz wool at both ends. Feed reaction gas (6 mL / min of propane, 3 mL / min of oxygen, 11 mL / min of nitrogen), raise the temperature to 550°C for reaction, and conduct online chromatographic analysis. (Its photo, schematic diagram of the preparation process are as follows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com