Hot melting device for waste copper foil tape recycling

A hot-melt device, copper foil adhesive technology, applied in transportation and packaging, cleaning methods and utensils, solid waste removal, etc., can solve the problems of uneven heating of copper foil tape, difficulty in winding, etc., and improve the dust collection effect , easy to roll, prevent the effect of high or low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

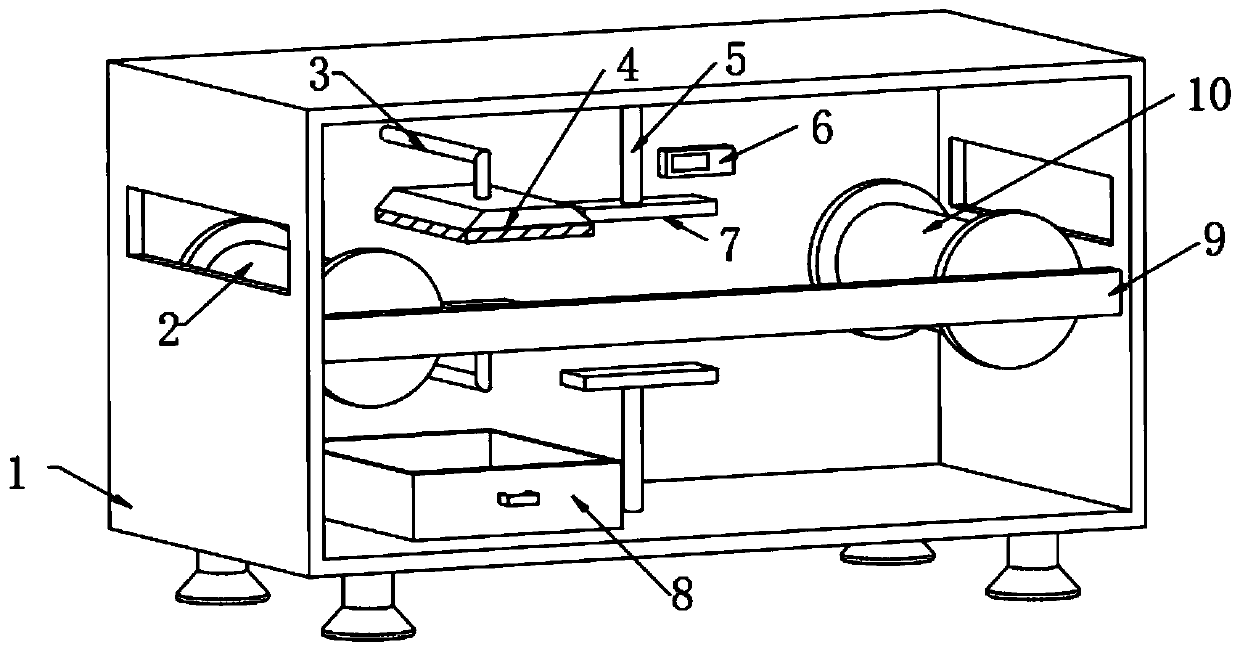

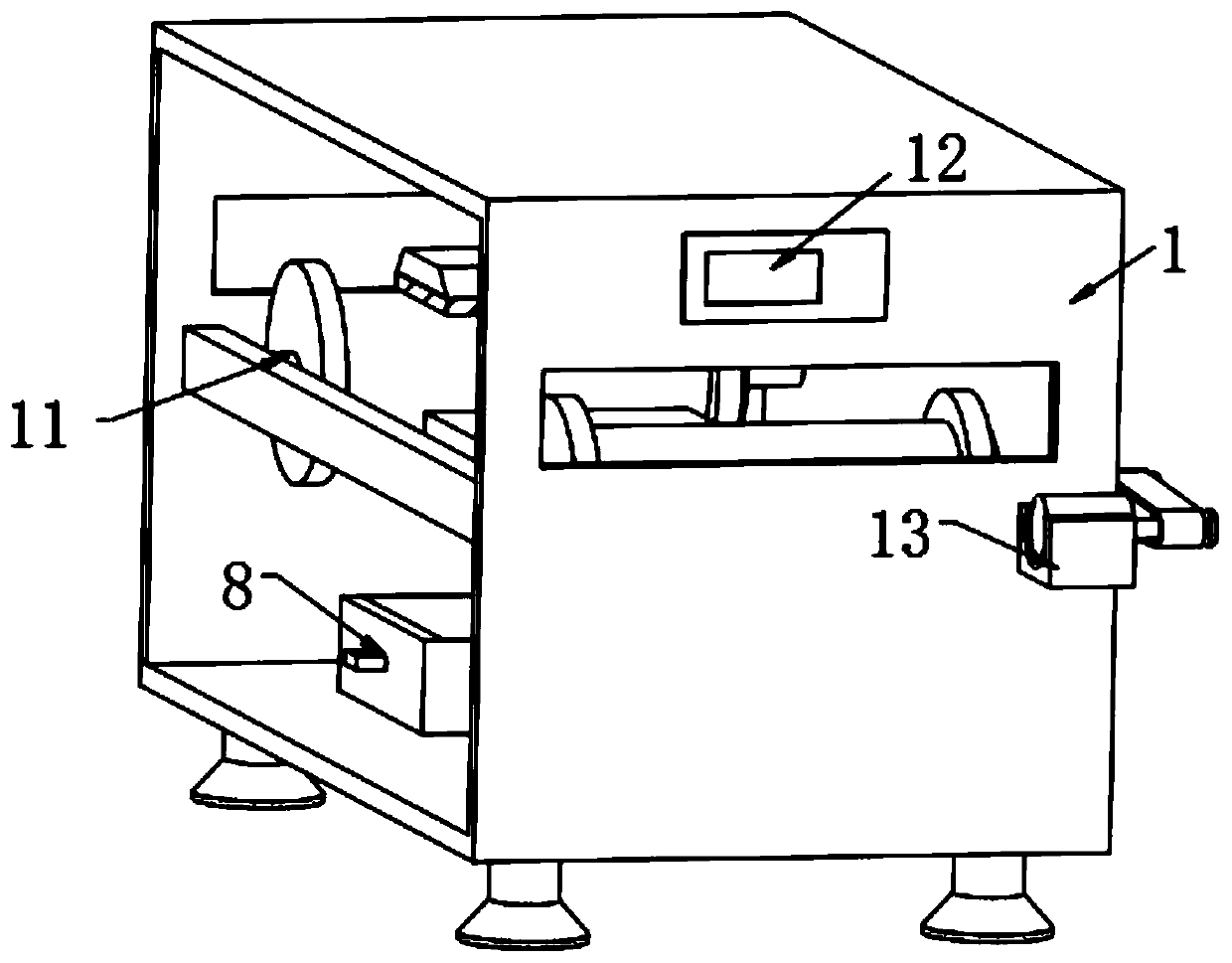

[0026] refer to figure 1 and figure 2 , a hot-melt device for recycling waste copper foil tape, comprising a recovery box 1, the top outer wall and the bottom inner wall of the recovery box 1 are welded with a fixing rod 5, and the other ends of the fixing rod 5 are fixed with a heating plate 7 by screws, One side of the inner wall of the recovery box 1 is fixed with a temperature display mechanism through screws, and the inner wall of the recovery box 1 is welded with a cleaning mechanism, and one side of the outer wall of the recovery box 1 is fixed with a motor base through screws, and the outer wall of the motor base is fixed with a motor. 13. The same horizontal plate 9 is welded on both sides of the inner wall of the recovery box 1, and the outer wall of one side of the horizontal plate 9 and the inner wall of the recovery box 1 are connected with two rotating rods 11 through bearings.

[0027] Wherein, the temperature display mechanism includes a temperature sensor 6,...

Embodiment 2

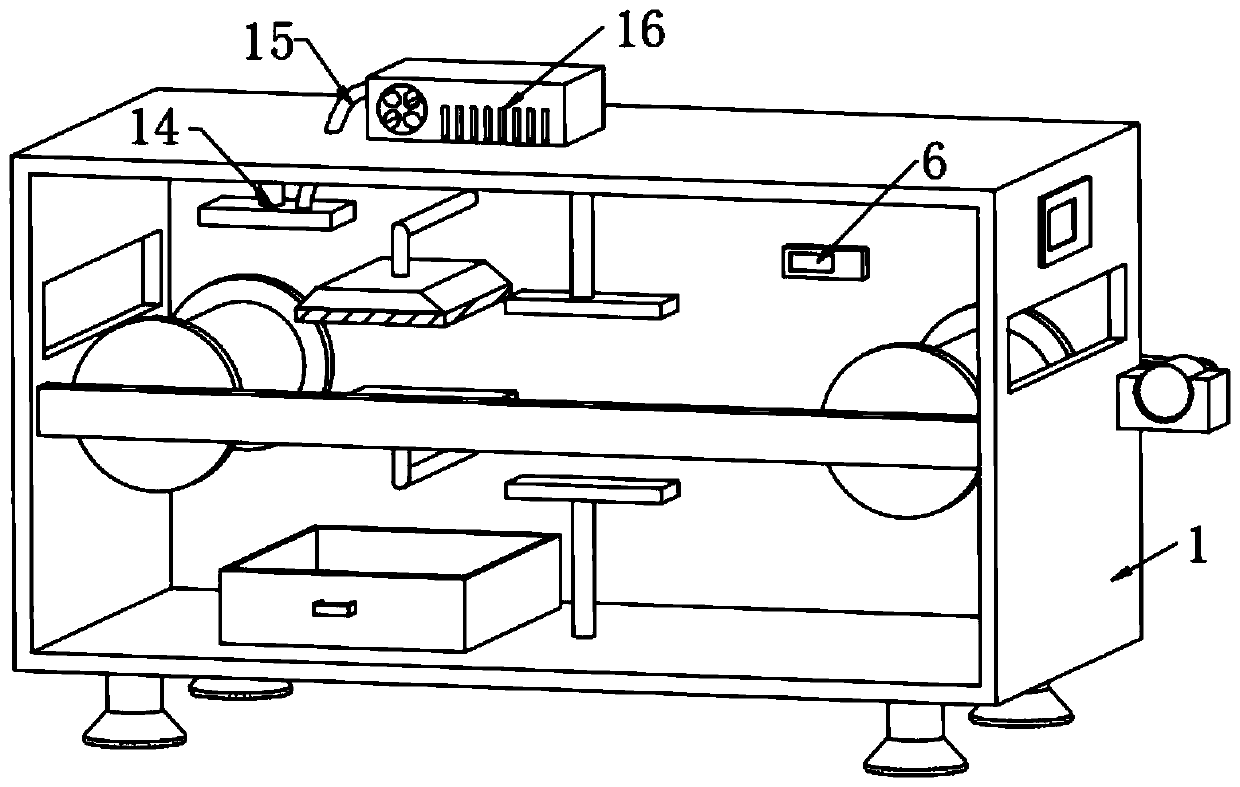

[0033] refer to image 3 , a hot-melt device for recycling waste copper foil tape, also includes a vacuum cleaner 16 welded to the top outer wall of the recovery box 1, the top inner wall of the recovery box 1 is fixed with a dust suction plate 14 by screws, and the top of the dust suction plate 14 The inner wall and the input end of the vacuum cleaner 16 are connected with the same dust guide pipe 15 through flanges, and the dust collector 16 is opened to absorb the dust raised by the cleaning brush 4 into the vacuum cleaner 16, which improves the durability of the device. Vacuum effect.

[0034] Working principle: Connect the device to the power supply, turn on the motor 13, the motor drives the rotating rod 11 to rotate, and then the copper foil tape starts to drive, the cleaning brush 4 cleans the outer walls of both sides of the copper foil tape, and the heating plate 7 is turned on, and the heating plate 7 The copper foil tape is softened, the temperature sensor 6 detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com