Dust removing device of high-speed wire and rod rolling machine

A technology of bar rolling mill and dust removal device, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of dust pollution, affecting the normal operation of electrical equipment, falling off, etc., achieving low input cost and improving field work. Condition, the effect of simple post-maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

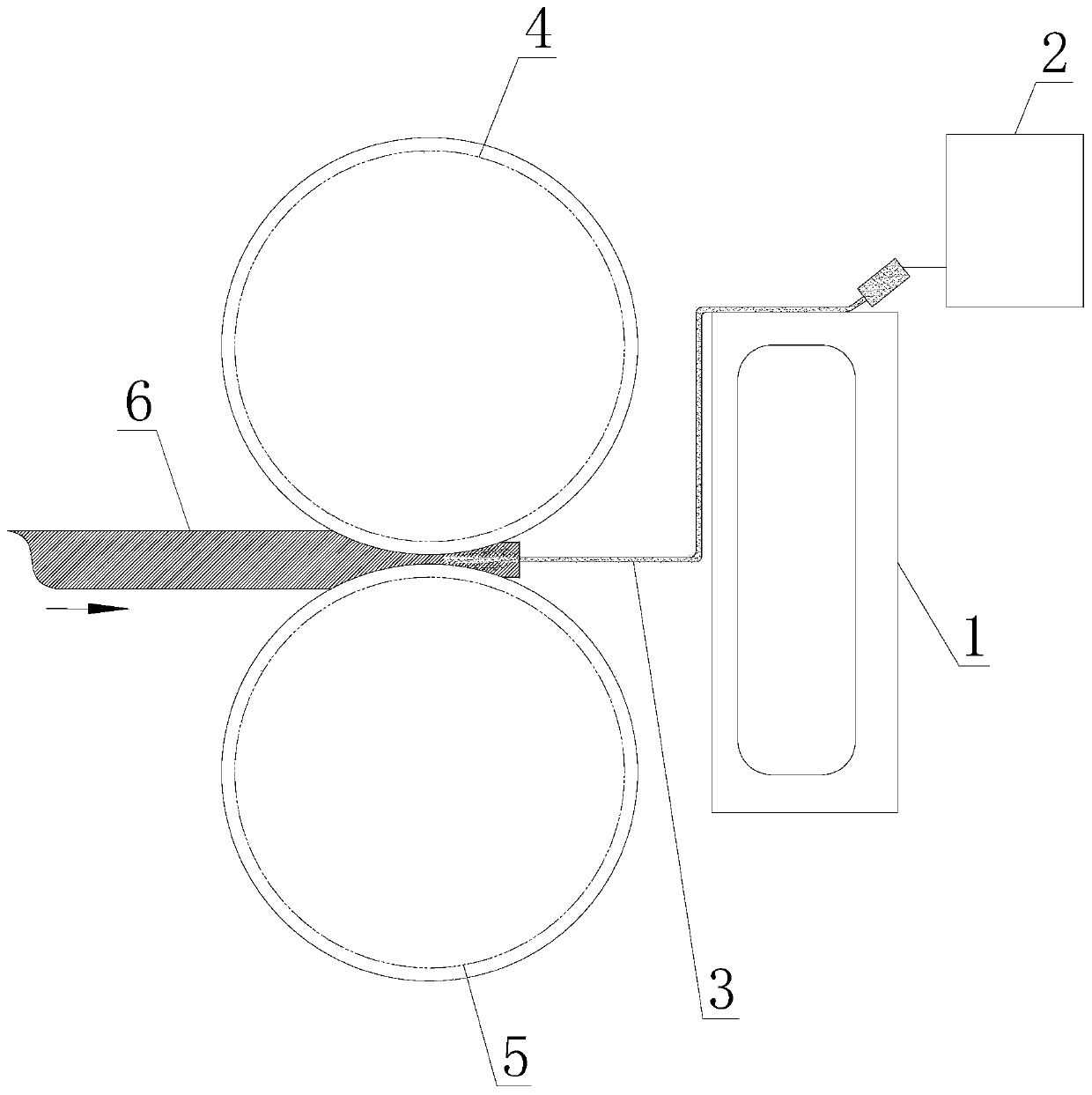

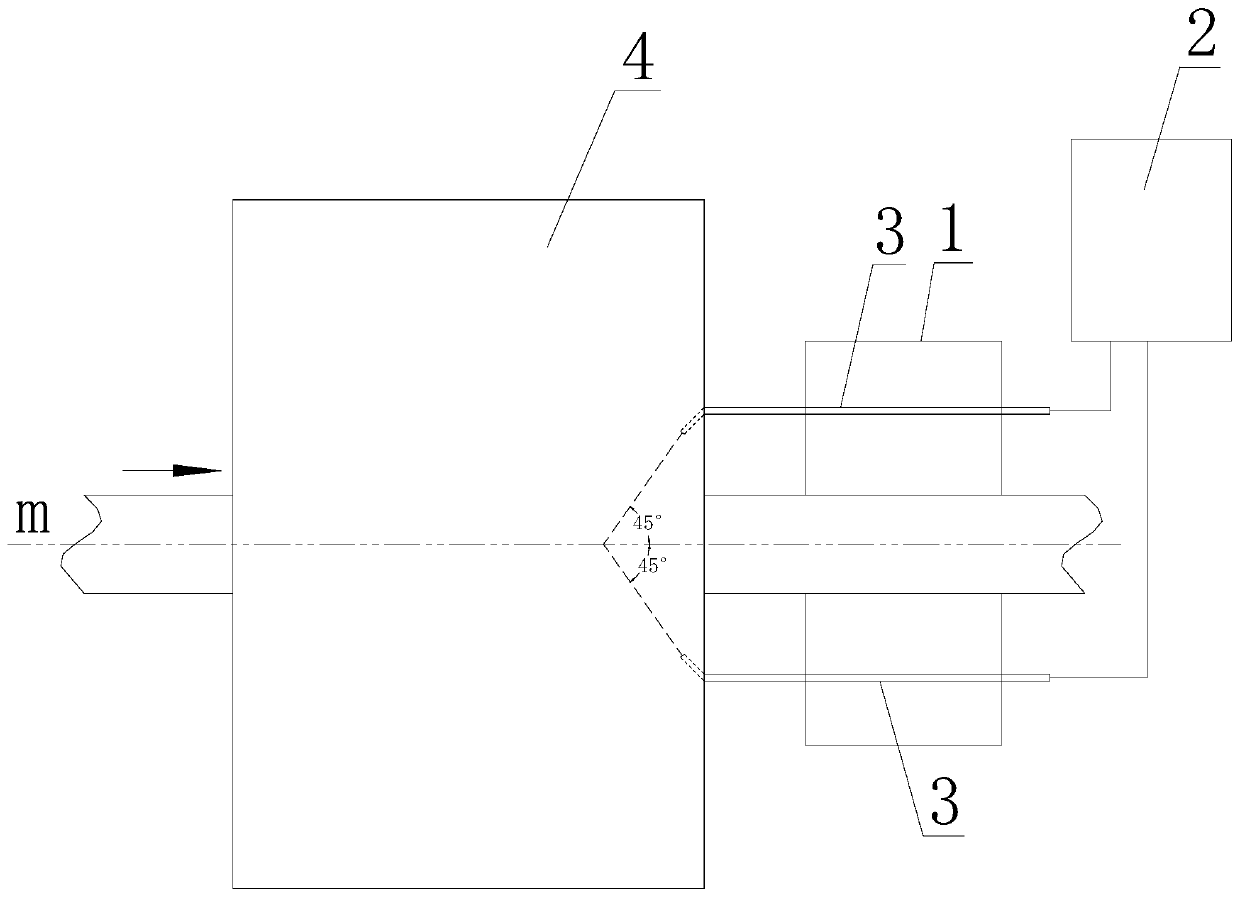

[0012] Such as figure 1 , figure 2 As shown, the dust removal device for a high-speed wire and bar mill includes a water spray pipe 3 installed on the guide 1 at the exit of the rolling mill and connected with the high-pressure water source 2. The nozzle of the water spray pipe 3 is aligned with the upper roll 4 and The deformation area of the rolled piece between the lower rolls 5 ensures that the water spray pipe 3 can cover the rolling piece 6 being deformed in the deformation area of the rolled piece with water when it is working; in this embodiment, the water spray pipe 3 has two groups, two The groups of water spray pipes 3 are distributed on the left and right sides of the deformation area of the rolled piece, and the nozzles of each group of water spray pipes 3 are aimed at the deformation area of the rolled piece be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com