Rice protein nutrition powder (tablet) capable of enhancing gastrointestinal tract health and production method thereof

A rice protein, production method technology, applied in protein food processing, protein food ingredients, food science and other directions, can solve the problem of high cost of raw materials, achieve good taste, improve constipation, and reduce flatulence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

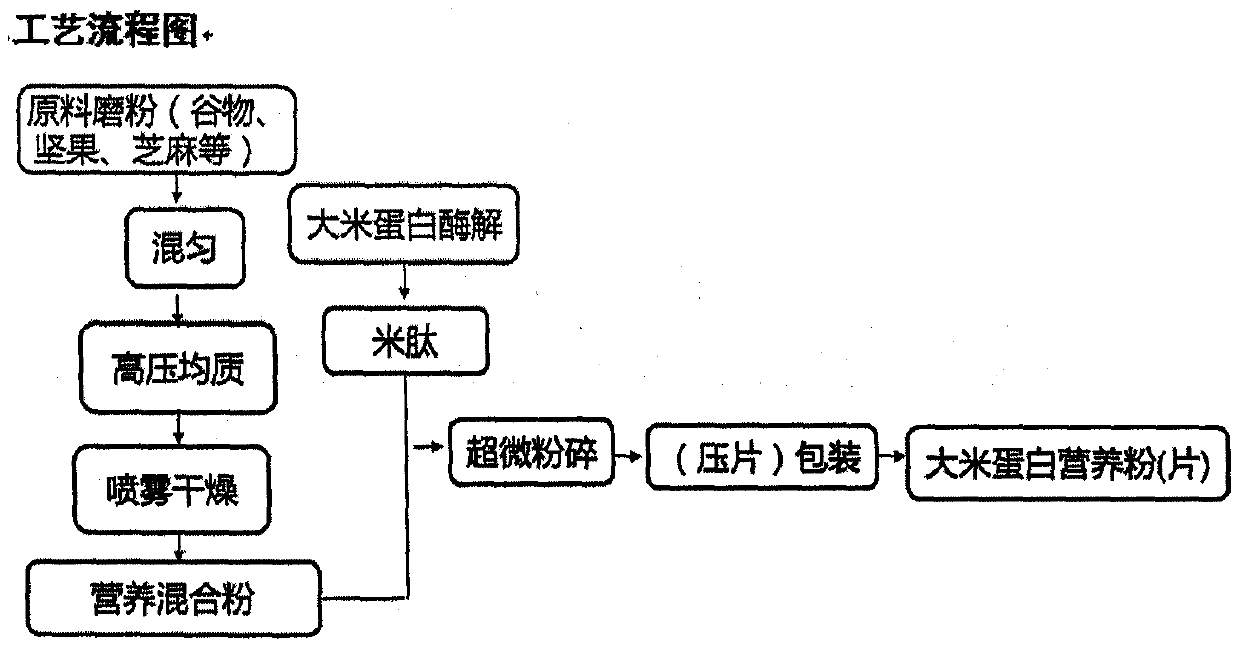

Image

Examples

Embodiment 1

[0028] A kind of rice protein nutrition powder (tablet) that strengthens gastrointestinal health and production method thereof, the steps are as follows:

[0029] (1) Grinding: Take 50 parts of rice, 10 parts of barley, 10 parts of wheat, 10 parts of oats, 1 part of job's tears, 1 part of lotus seeds, 1 part of red dates, 0.1 parts of walnuts, 0.1 parts of cashew nuts, 0.1 parts of pine nuts, and 0.1 parts of hazelnuts , 0.1 part of pumpkin seeds, 1 part of sesame. Grinding the above raw materials into powder;

[0030] (2) Mixing and tempering: Add 1 part of milk powder and 1 part of fructooligosaccharide to the above raw material powder, add water and mix evenly through a colloid mill;

[0031] (3) High-pressure homogenization: homogenization pressure (140-150MPa), time 20-25min, to obtain homogeneous slurry;

[0032] (4) Spray drying: the drying temperature is 140-150°C, and the drying time is 15-20s;

[0033] (5) Dissolve rice protein in water to obtain a protein solutio...

Embodiment 2

[0037] A kind of rice protein nutrition powder (tablet) that strengthens gastrointestinal health and production method thereof, the steps are as follows:

[0038] (1) Grinding: 30 parts of rice, 5 parts of barley, 5 parts of wheat, 5 parts of oats, 5 parts of barley, 5 parts of lotus seeds, 5 parts of red dates, 2 parts of walnuts, 2 parts of cashew nuts, 2 parts of pine nuts, 2 parts of hazelnuts, 2 parts of pumpkin seeds, 2 parts of sesame seeds, milk powder, 2 parts of inulin, 2 parts of vitamins, edible salt, fructooligosaccharides, ground into powder;

[0039] (2) Mixing and tempering: Add 2 parts of milk powder and 2 parts of fructooligosaccharide to the above raw material powder, add water and mix evenly through a colloid mill;

[0040] (3) High-pressure homogenization: homogenization pressure (140-150MPa), time 20-25min, to obtain homogeneous slurry;

[0041](4) Spray drying: the drying temperature is 140-150°C, and the drying time is 15-20s;

[0042] (5) dissolving ...

Embodiment 3

[0047] A kind of rice protein nutrition powder (tablet) that strengthens gastrointestinal health and production method thereof, the steps are as follows:

[0048] (1) Grinding: 25 parts of rice, 10 parts of barley, 10 parts of wheat, 10 parts of oats, 3.6 parts of barley, 3.6 parts of red dates, 3.6 parts of lotus seeds, 0.7 parts of walnuts, 0.7 parts of cashew nuts, 0.7 parts of pine nuts, 0.7 parts of hazelnuts, 0.7 parts of pumpkin seeds, 2 parts of sesame seeds, 2 parts of milk powder, ground into powder;

[0049] (2) Mixing and tempering: Add 2 parts of milk powder and 3 parts of fructooligosaccharide to the above raw material powder, add water and mix evenly through a colloid mill;

[0050] (3) High-pressure homogenization: homogenization pressure (140-150MPa), time 20-25min, to obtain homogeneous slurry;

[0051] (4) Spray drying: the drying temperature is 140-150°C, and the drying time is 15-20s;

[0052] (5) dissolving rice protein in water to obtain a protein solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com