Stretchable capacitor electrode-conductor structure and super capacitor

A capacitor electrode, conductor structure technology, applied in the direction of hybrid capacitor electrode, hybrid capacitor collector, hybrid capacitor electrolyte, etc., to achieve the effect of not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

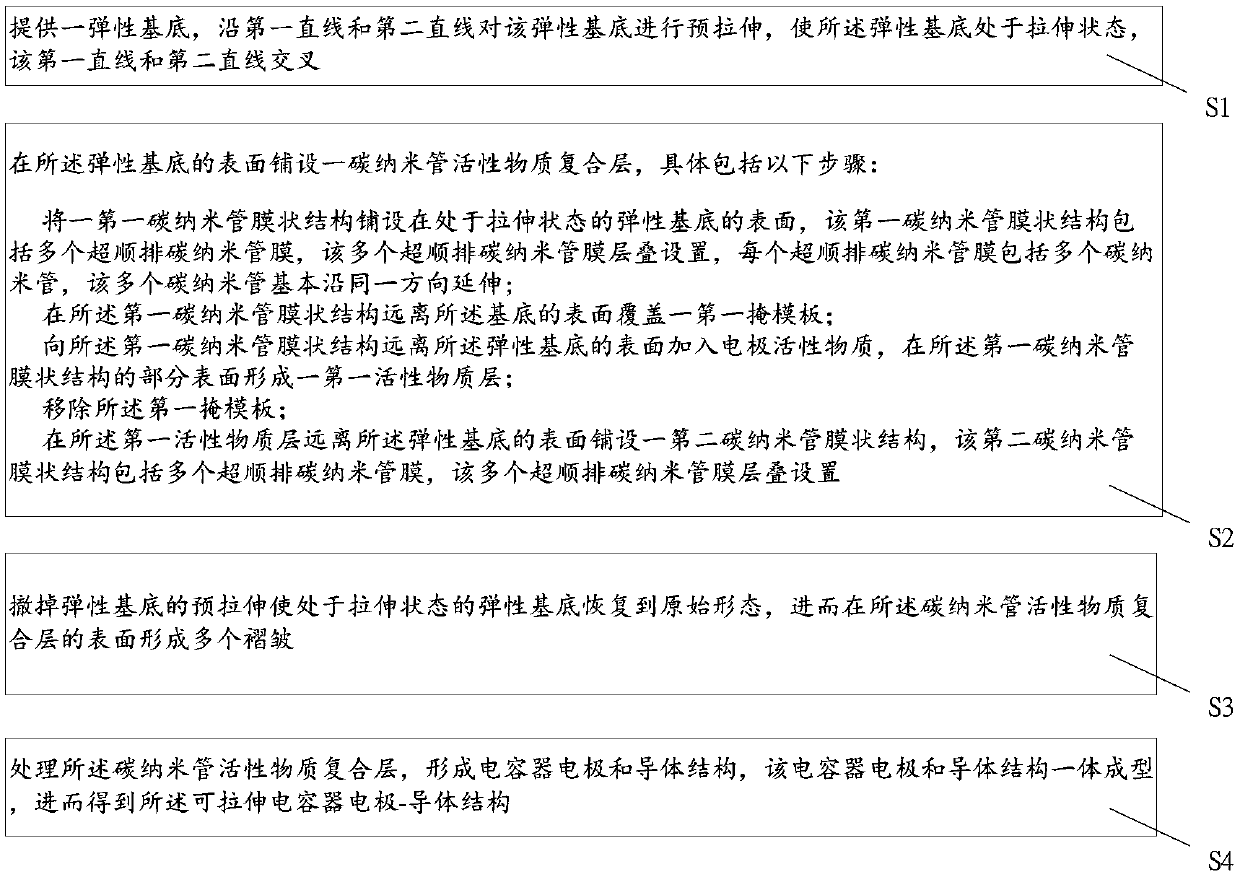

[0030] see figure 1 and 2 , an embodiment of the present invention provides a method for preparing a stretchable capacitor electrode-conductor structure, comprising the following steps:

[0031] Step S1, providing an elastic base, pre-stretching the elastic base along a first direction and a second direction, so that the elastic base is in a stretched state, and the first direction and the second direction intersect;

[0032] Step S2, laying a carbon nanotube active material composite layer on the surface of the elastic substrate, specifically includes the following steps:

[0033] S21, laying a first carbon nanotube film-like structure on the surface of the elastic substrate in a stretched state, the first carbon nanotube film-like structure includes a plurality of super-aligned carbon nanotube films, and the plurality of super-aligned carbon nanotube films The carbon nanotube films are stacked, and each super-aligned carbon nanotube film includes a plurality of carbon nano...

Embodiment 1

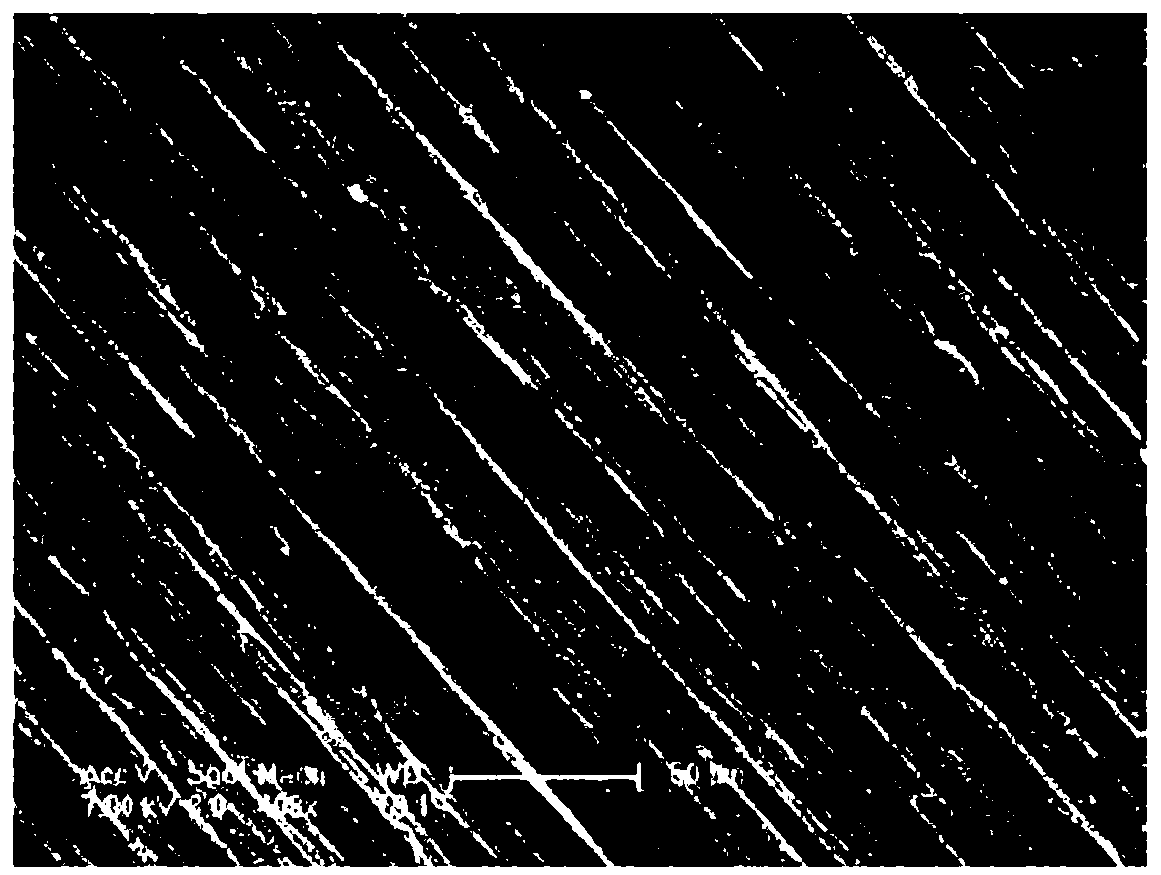

[0067]In this embodiment, a stretchable capacitor electrode-conductor structure is prepared, wherein the capacitor electrode part includes PDMS, superparallel carbon nanotube film and AC, and the conductor part is pure carbon nanotube. The preparation method includes: providing a PDMS substrate, respectively carrying out 150% pre-stretching of the PDMS substrate along the length and width of the rectangular PDMS substrate; The tube cross film is covered on the PDMS substrate in the stretched state; a polyethylene film is covered on the 6-layer super-parallel carbon nanotube cross film as a mask; 45 mg of activated carbon powder is dispersed in 60 mL of ethanol using a cell pulverizer to form a dispersion Liquid, use a pipette gun to take 6mL of dispersion liquid and evenly drop it on the part of the surface of the 6-layer super-parallel carbon nanotube cross film covering the mask plate, and form an AC active material layer after the ethanol evaporates until there are no obviou...

Embodiment 2

[0069] The difference between this embodiment and Embodiment 1 is only that the conductor structure cut from pure carbon nanotubes is different. see Figure 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com