Magnetic refrigeration heat exchanger and refrigeration heating system and method

A heat exchanger and magnetic refrigeration technology, applied in refrigeration and liquefaction, refrigerators, refrigeration components, etc., can solve the problems of large heat capacity of magnetic refrigeration heat exchangers, loss of magnetic core heat or cooling capacity, and difficulty in ductility. The effect of improving heat exchange efficiency, improving reliability and versatility, and solving the loss of direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

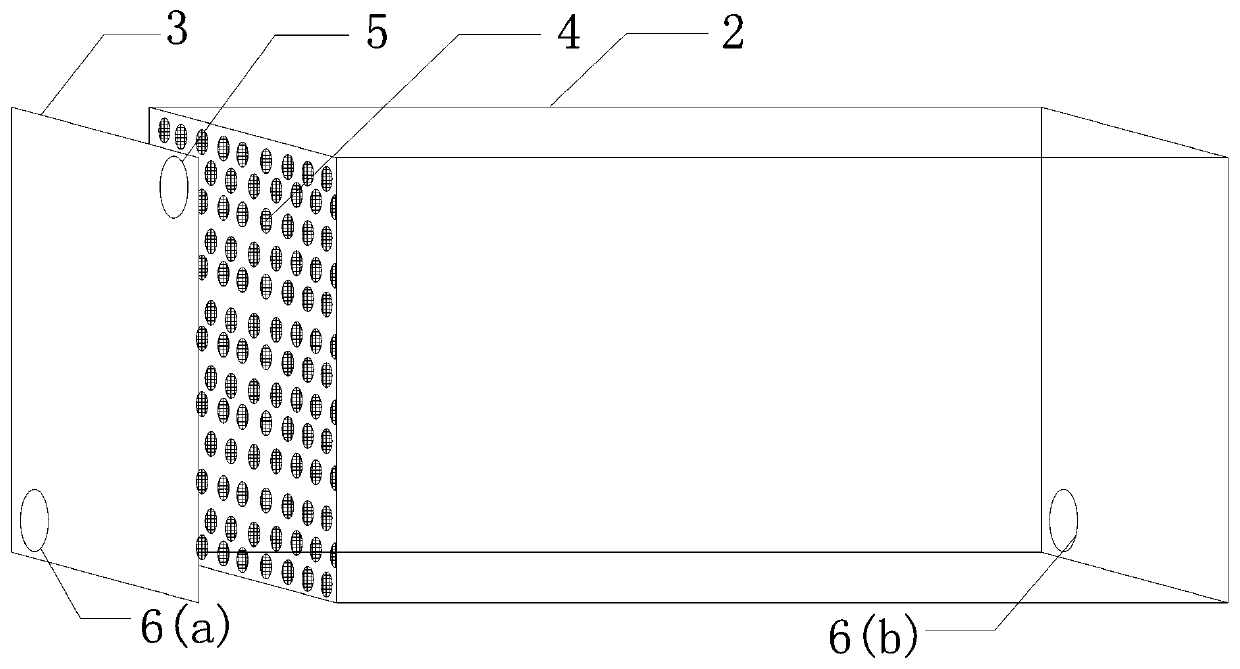

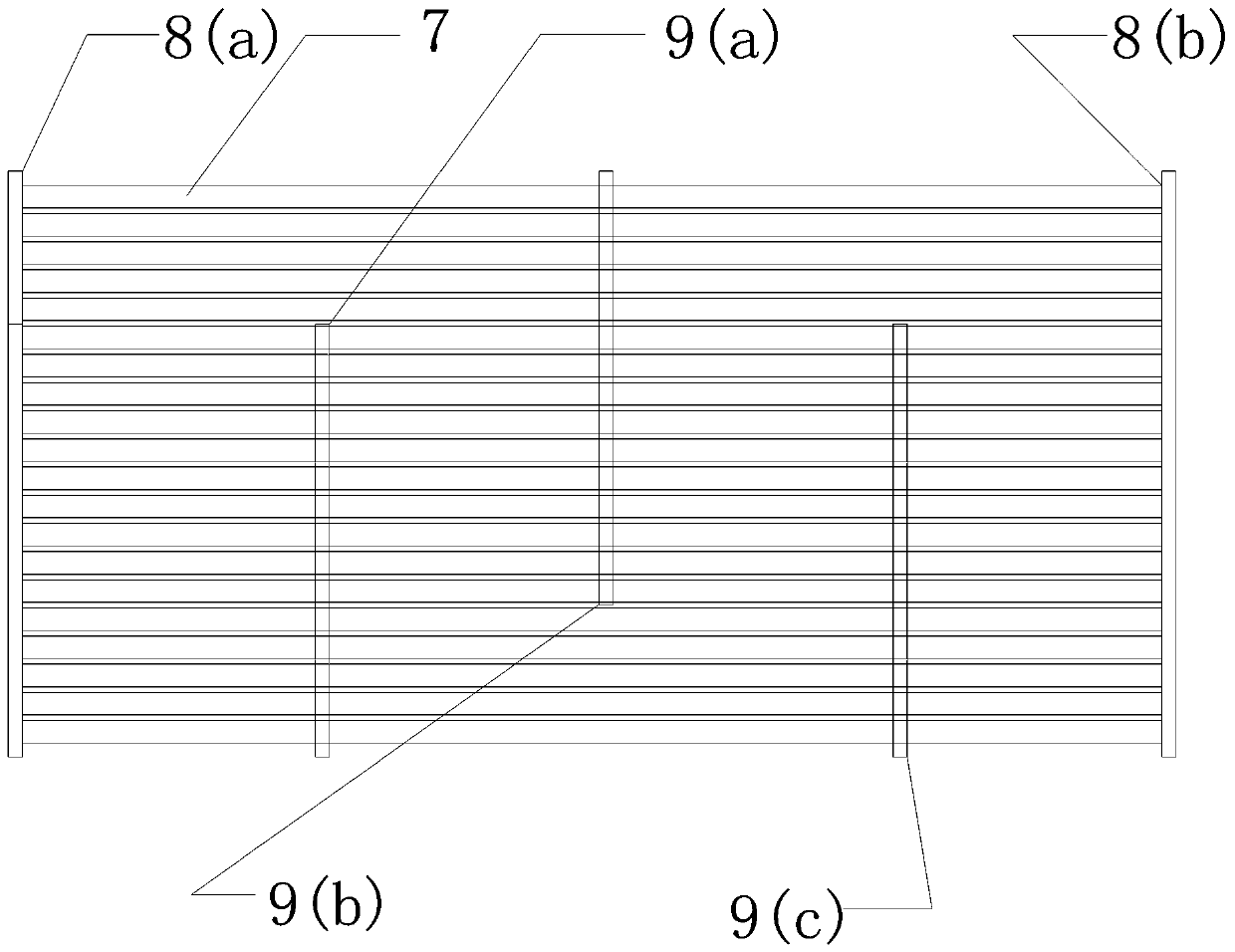

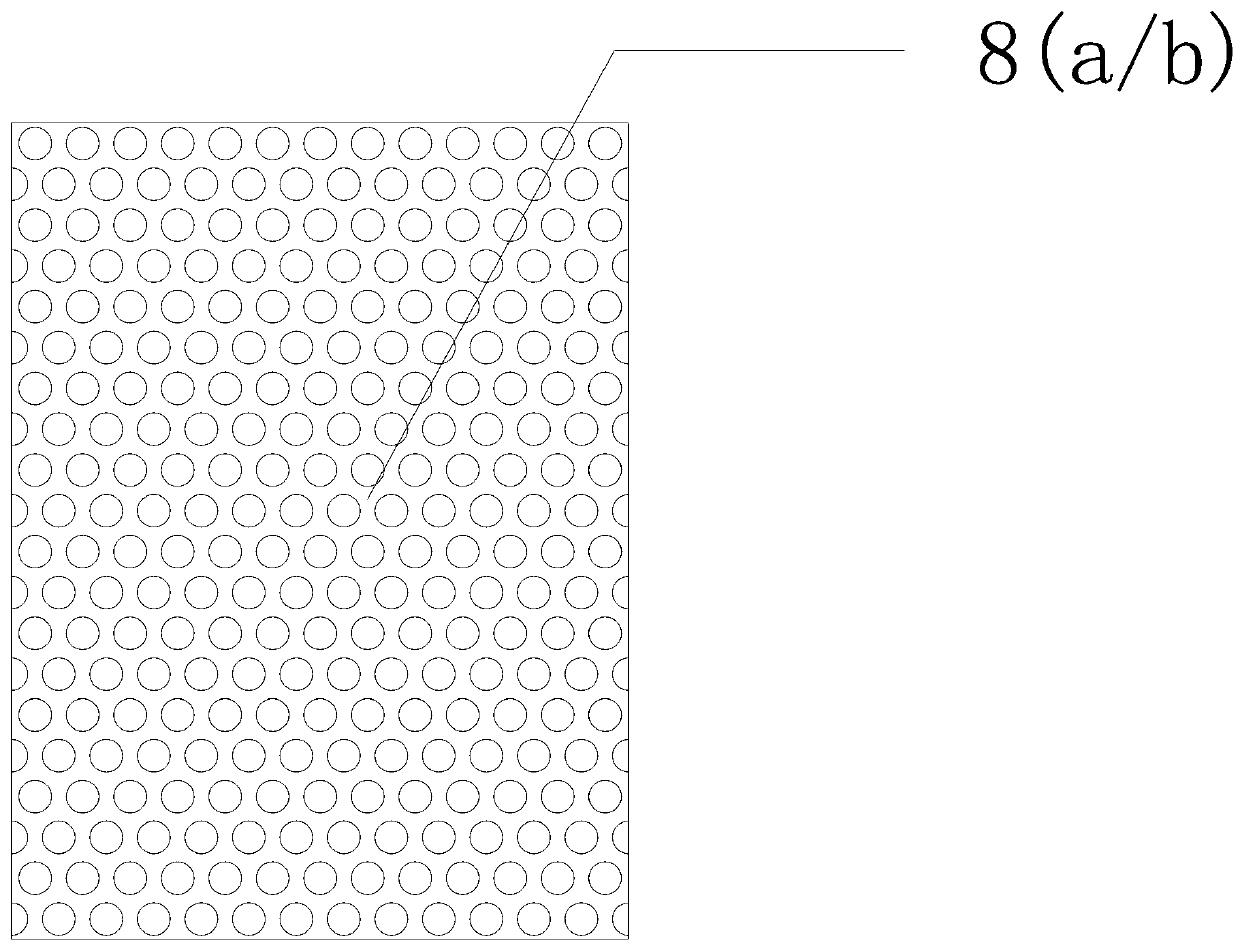

[0051] see Figure 1-10 , a magnetic refrigeration heat exchanger, which includes a rectangular heat exchanger 1, the rectangular heat exchanger 1 includes a heat exchanger shell 2, the inside of the heat exchanger shell 2 is installed with a magnetic working medium 12 The capillary matrix 4 is equipped with a cover plate 3 at both ends of the heat exchanger shell 2 and the capillary matrix 4 is packaged inside it; the upper edge of the cover plate 3 on both sides or the upper heat exchanger shell 2 The first through hole 5 for air intake and exhaust is processed in different processes in the interior; the second through hole 6 for circulating heat and cold fluid is processed on the lower edge of the cover plate 3 on both sides or the upper heat exchanger shell 2 (a) and the third through hole 6 (b). By adopting the magnetic refrigeration heat exchanger with the above structure, it adopts the magnetic refrigeration cycle to realize cyclic refrigeration or heating. It uses the...

Embodiment 2

[0061] according to figure 1 , the rectangular heat exchanger 1 is 40mm wide along the moving direction of the magnetic field, 30mm high along the magnetic field height direction, and 80mm long. . The shell and cover of the heat exchanger are cut or welded from 3mm aluminum alloy. The junction of the heat exchanger shell 2 and the cover plate 3 is welded with a 5mm boss for loading the silicone sealing strip and fixing the cover plate. According to the different processes in the heat exchanger, taking the four processes as an example, open a 5mm first through hole 5 on the cover plate or shell of the heat exchanger to connect the gas path through flanges or welded pipes; the cover plate of the heat exchanger Or open two 5mm second through holes 6 (a) and third through holes 6 (b) on the lower edge of the housing to connect the liquid circuit through flanges or welded pipes. The outer wall of the heat exchanger is affixed with a vacuum insulation board to insulate the heat e...

Embodiment 3

[0065] The refrigeration and heating system constructed by the above-mentioned magnetic refrigeration heat exchanger includes a rectangular heat exchanger 1 and a data acquisition and control system 17; the rectangular heat exchanger 1 cooperates with a movable magnetic field 13 arranged on its periphery, so that A heat storage container 14 and a cold storage container 15 are connected in parallel between the second through hole 6 (a) and the third through hole 6 (b) of the rectangular heat exchanger 1, and the outlet of the heat storage container 14 is connected to the heat storage The inlet of the side water pump 21 (a) is connected, and the outlet of the heat storage side water pump 21 (a) is connected to one inlet of the first electric three-way valve 18 (c); the other of the first electric three-way valve 18 (c) The inlet is connected to the outlet of the cold storage side water pump 21 (b), and the inlet of the cold storage side water pump 21 (b) is connected to the outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com