A kind of organic coating treatment method of titanium dioxide

A titanium dioxide and treatment method technology, which is applied in the field of organic coating treatment of titanium dioxide, can solve the problems of increased cleaning frequency of steam powder bag filters, incomplete organic coating, and low film coating rate of organic agents, so as to reduce the cleaning system frequency , reduce surface free energy, weaken the effect of surface polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

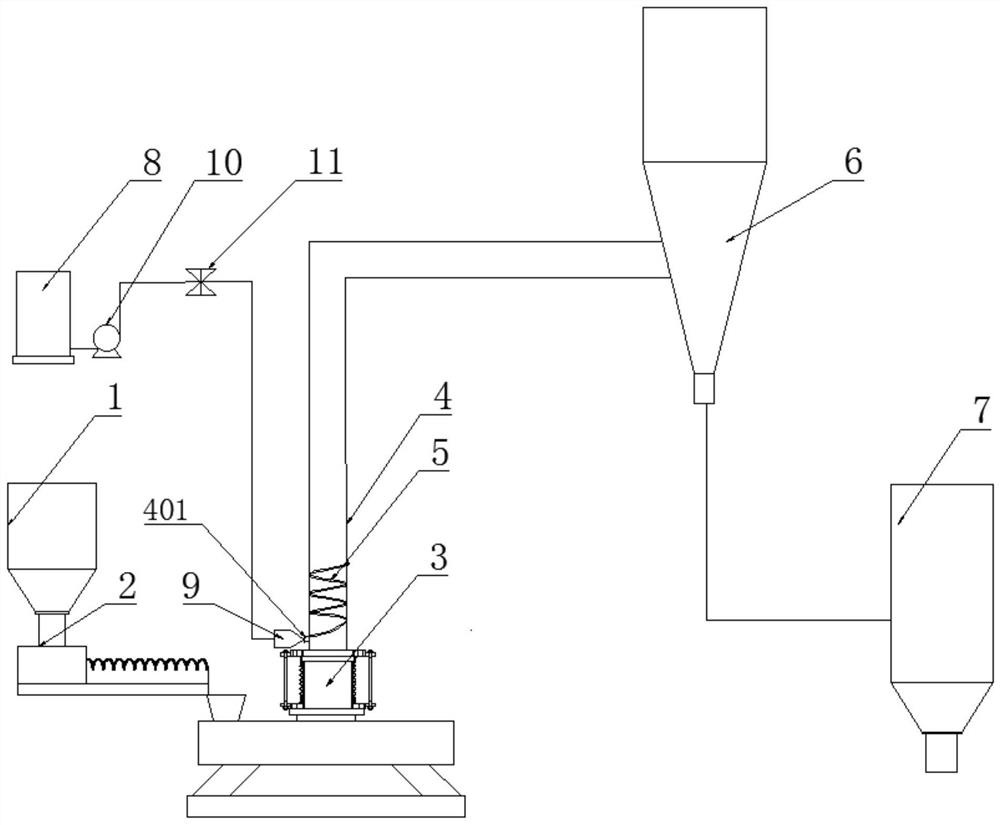

[0022] 1) A titanium dioxide steam powder processing system is adopted, which includes a steam powder silo 1 and an organic silicon material tank 8. The outlet of the steam powder silo 1 is connected with a screw conveyor 2 and a steam powder machine 3 in sequence. The discharge port of the powder machine 3 is connected with a powder bag filter 6 through the conveying ascending pipeline 4, and the discharge port of the powder bag filter 6 is connected with a finished product bin 7; the discharge port of the organic silicon material tank 8 passes through The pipeline is connected with an atomizing spray gun 9, and the atomizing spray gun 9 is a steam atomizing spray gun; a diaphragm pump 10 and a damper 11 are arranged successively on the pipeline between the organosilicon material tank 8 and the atomizing spray gun 9, so that the organic agent flow tends to be stable. An organic agent inlet 401 is provided on the conveying ascending pipeline 4 close to the outlet of the steam ...

Embodiment 2

[0026] 1) A titanium dioxide steam powder treatment system is adopted, which includes a steam powder silo 1, an organic silicon material tank 8 and an atomizing spray gun 9, and the outlet of the steam powder silo 1 is connected with a screw conveyor 2, a steam powder machine 3, the steam powder bag filter 6 is connected to the discharge port of the steam powder machine 3 through the conveying ascending pipeline 4, and an organic agent inlet 401 is provided on the conveying ascending pipeline 4 near the discharge port of the steam powder machine 3, and the organic agent The discharge port of the silicon material tank 8 is communicated with the feed port of the atomizing spray gun 9 through a pipeline, and the nozzle of the atomizing spray gun 9 is communicated with the organic agent inlet 401 on the conveying ascending pipeline 4. A diaphragm pump 10 and a damper 11 are successively arranged on the pipeline between the atomizing spray gun 9, so that the flow of the organic agen...

Embodiment 3

[0030]1) A titanium dioxide steam powder processing system is adopted, which includes a steam powder silo 1 and an organic silicon material tank 8. The outlet of the steam powder silo 1 is connected with a screw conveyor 2 and a steam powder machine 3 in sequence. The discharge port of the powder machine 3 is connected with a powder bag filter 6 through the conveying ascending pipeline 4, and the discharge port of the powder bag filter 6 is connected with a finished product bin 7; the discharge port of the organic silicon material tank 8 passes through The pipeline is connected with an atomizing spray gun 9, and the atomizing spray gun 9 is a steam atomizing spray gun; a diaphragm pump 10 and a damper 11 are arranged successively on the pipeline between the organosilicon material tank 8 and the atomizing spray gun 9, so that the organic agent flow tends to be stable. An organic agent inlet 401 is provided on the conveying ascending pipeline 4 close to the outlet of the steam p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com