Polar polymer microparticles, preparation method and applications thereof

A technology of polar polymers and microparticles, which is applied in the fields of alkali metal compounds, chemical instruments and methods, and water pollutants. High efficiency, high softness, and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

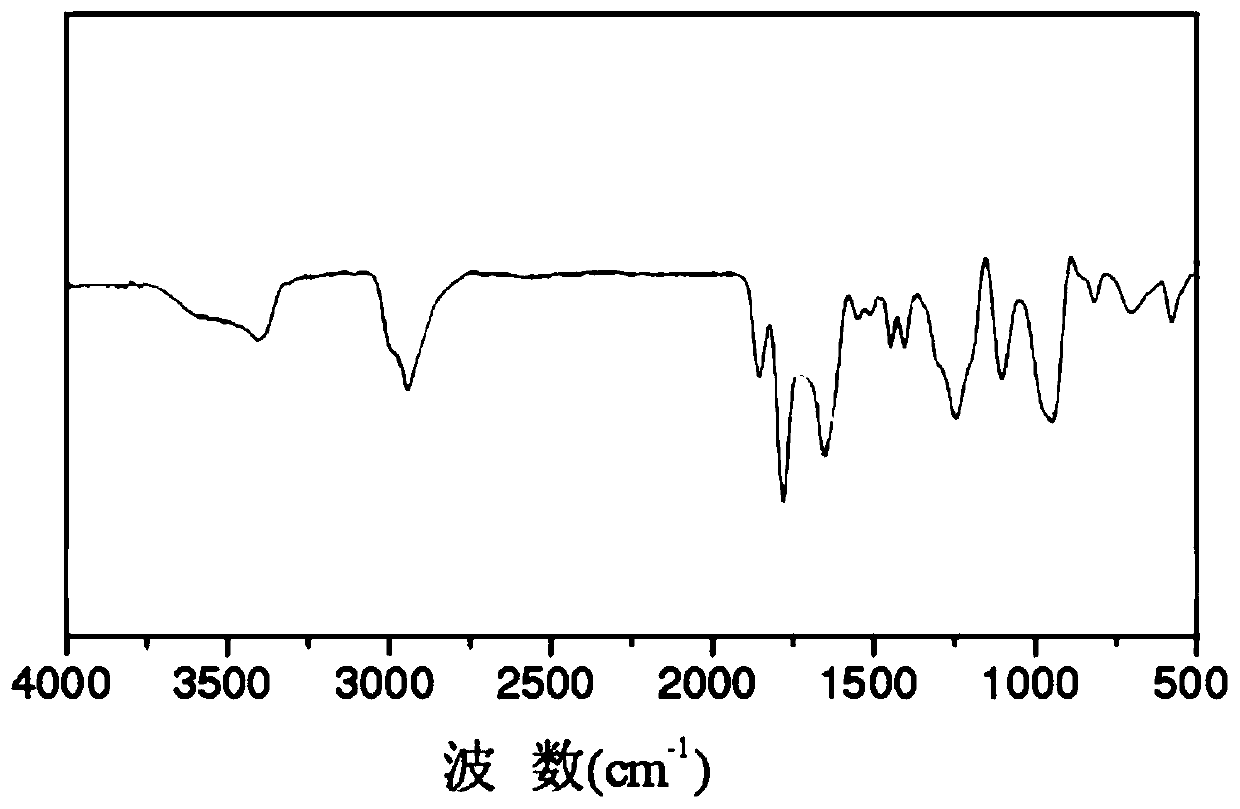

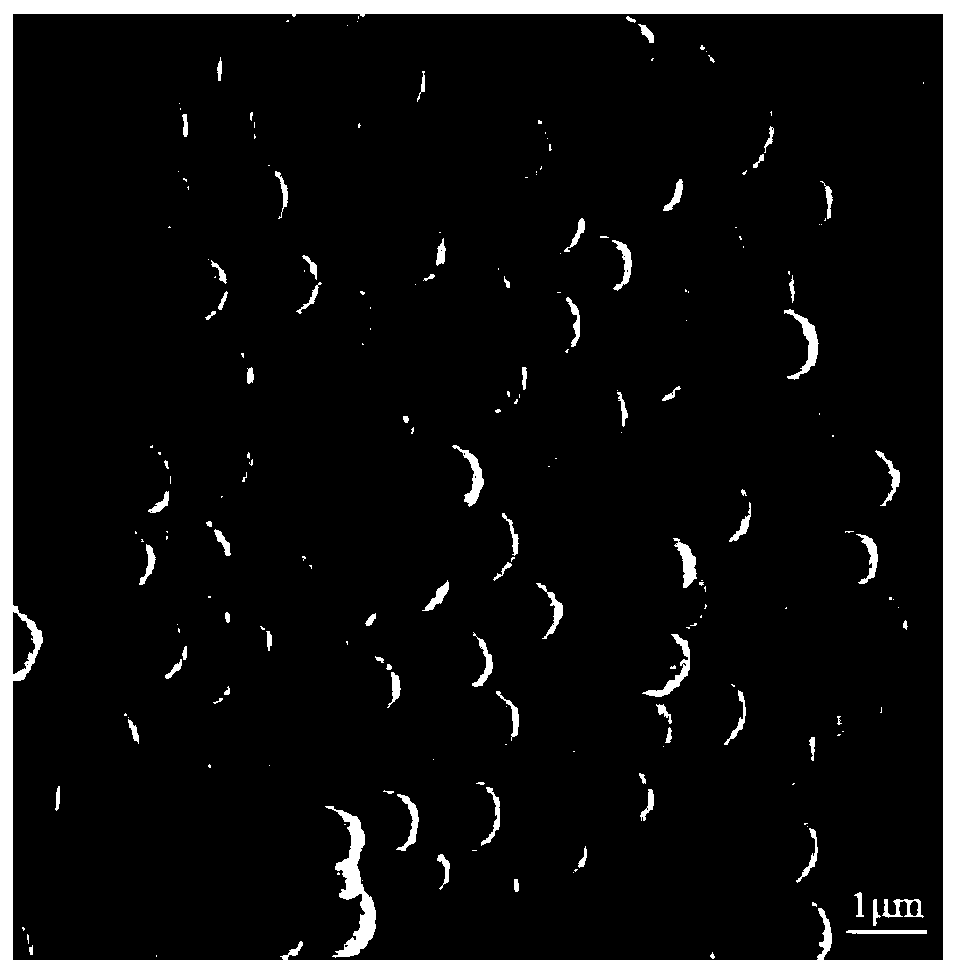

[0029] The preparation method of polar polymer microparticles comprises the following steps:

[0030] 1) prepare maleic anhydride, N-vinylpyrrolidone and vinyl ether in a molar ratio of 1:0.5-2:1;

[0031] 2) maleic anhydride and an organic solvent are added to the reaction vessel according to the solid-liquid ratio of 1:5-8 (g / mL), and stirred until the MA is completely dissolved into a clear and transparent homogeneous solution;

[0032] 3) Add N-vinyl pyrrolidone, vinyl ether and initiator into the reaction vessel, empty it with nitrogen, and mix evenly to obtain a polymerization reaction system. The mass fraction of the initiator in the polymerization reaction system is 1-5%. When the fraction is less than 1%, monodisperse microspheres cannot be obtained, but only some smaller random particles can be obtained. As the concentration of initiator increases, the yield of microspheres gradually increases. When the mass fraction of initiator is greater than When the concentrati...

Embodiment 2

[0040] The preparation method of polar polymer microparticles comprises the following steps:

[0041] 1) prepare maleic anhydride, N-vinylpyrrolidone and vinyl ether in a molar ratio of 1:1.2:1;

[0042] 2) maleic anhydride and tetrahydrofuran are added in the there-necked flask according to the solid-to-liquid ratio of 1:6 (g / mL), and the homogeneous solution is stirred until the MA is completely dissolved;

[0043] 3) adding N-vinylpyrrolidone, vinyl ether and lauroyl peroxide into the reaction vessel, emptying through nitrogen, and mixing uniformly to obtain a polymerization reaction system, and the mass fraction of lauroyl peroxide in the polymerization reaction system is 1.5%;

[0044] 4) The polymerization reaction system was heated up to 65 in 30 min, and the polymerization reaction was carried out at a stirring speed of 500 rpm for 4 h. After the reaction, the reaction was filtered, washed and dried to obtain P(MA-DE-NVP) microparticles.

Embodiment 3

[0046] The preparation method of polar polymer microparticles comprises the following steps:

[0047] 1) prepare maleic anhydride, N-vinylpyrrolidone and vinyl ether in a molar ratio of 1:1.2:1;

[0048] 2) maleic anhydride and tetrahydrofuran are added in the there-necked flask according to the solid-to-liquid ratio of 1:6 (g / mL), and the homogeneous solution is stirred until the MA is completely dissolved;

[0049] 3) N-vinyl pyrrolidone, vinyl ether, lauroyl peroxide, hydroxyapatite and α-amino acid are added to the reaction vessel, emptied with nitrogen, and uniformly mixed to obtain a polymerization reaction system. In the polymerization reaction system, lauroyl peroxide is obtained. The mass fraction of α-amino acid is 0.15%, the mass fraction of hydroxyapatite is 0.06%, and the mass fraction of a-amino acid is 1.5%;

[0050] 4) The polymerization reaction system was heated up to 65 in 30 min, and the polymerization reaction was carried out at a stirring speed of 500 rp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com